Multilayer PCB

- Home

- Multilayer PCB

Multilayer PCB

- Home

- Multilayer PCB

Advantages of multilayer PCB

Why Choose Us

Advanced Multilayer PCB Manufacturing

Our company specializes in the production of high-quality multilayer PCBs, utilizing state-of-the-art equipment and technology. We are capable of producing multilayer PCBs with a high layer count, ensuring stability, reliability, and optimal electrical performance. Whether it's for complex industrial control systems, medical devices, or automotive applications, our manufacturing processes meet the highest industry standards, providing robust solutions for demanding projects.

Fast Delivery

With a well-organized production system and efficient workflow, we minimize lead times for multilayer PCB manufacturing. Our experienced team and optimized supply chain allow us to quickly turn around even large and complex orders without compromising on quality. This ensures that our clients can meet tight project deadlines and maintain a competitive edge in their respective markets.

Flexible Customization

We understand that different industries and projects have unique requirements, which is why we offer a wide range of customization options for multilayer PCBs. From material selection to layer count, thickness, and layout design, we collaborate closely with clients to ensure the PCBs are tailored to specific needs. Whether it's for high-density, high-speed circuits or specific thermal management needs, we provide flexible solutions that cater to various industry demands.

Strict Quality Control

Quality is our top priority, and we implement rigorous testing and inspection procedures throughout every stage of the multilayer PCB production process. From raw material inspection to in-process quality checks and final testing, we ensure that each PCB meets or exceeds international standards. Our commitment to quality ensures that our PCBs deliver reliable, long-term performance in even the most critical applications, giving clients peace of mind.

production capacity

Items | Rigid |

Material | Lead-free、Halogen-free、H-Tg、Low loss |

Layers | 1-40L |

Max cut lamination size | Min3*3mm-Max1200mm |

Final board thickness | 0.18-5.0mm |

Min Final Hole size | 0.075mm |

Aspect Ratio | 14:1 |

Inner layer Line Width/Space | 0.05mm |

Copper Foil Thickness (Inner Layers) | 1/2oz~3.0oz |

Min dielectric layer thickness | 50um |

Copper Foil Thickness (Outer Layers) | Hoz-14oz |

Copper to drill distance | 0.2mm |

Out layer Line width/space | 0.05mm |

Min SMD width | 0.05mm |

Max Solder Mask Plug Hole Diameter | 0.5mm |

solder mask strip width | 0.075mm(Green/1OZ) |

Final Set Size Tolerance | ±0.1mm/limit±0.05mm |

Min Hole to board edge Distance | 0.15mm |

Min Beveling angle Tolerance | ±3-5° |

Layer to layer Tolerance | ≤0.075mm(1-6L) |

Inner layer Min PTH Annular Ring | 0.15mm |

Out layer Min PTH Annular ring | 0.15mm |

Surface Treatment | OSP、HASL 、ENIG、Gold Finger、Plating Gold 、ENEPIG、IMM TIN、IMM AG |

Warp&Twist | ≤0.5% |

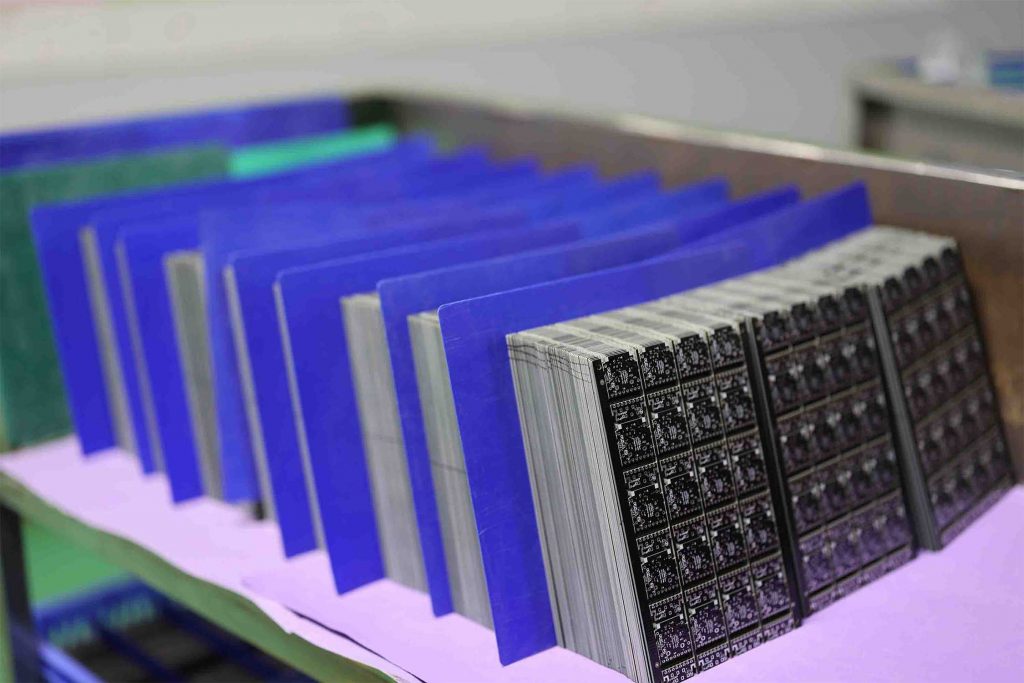

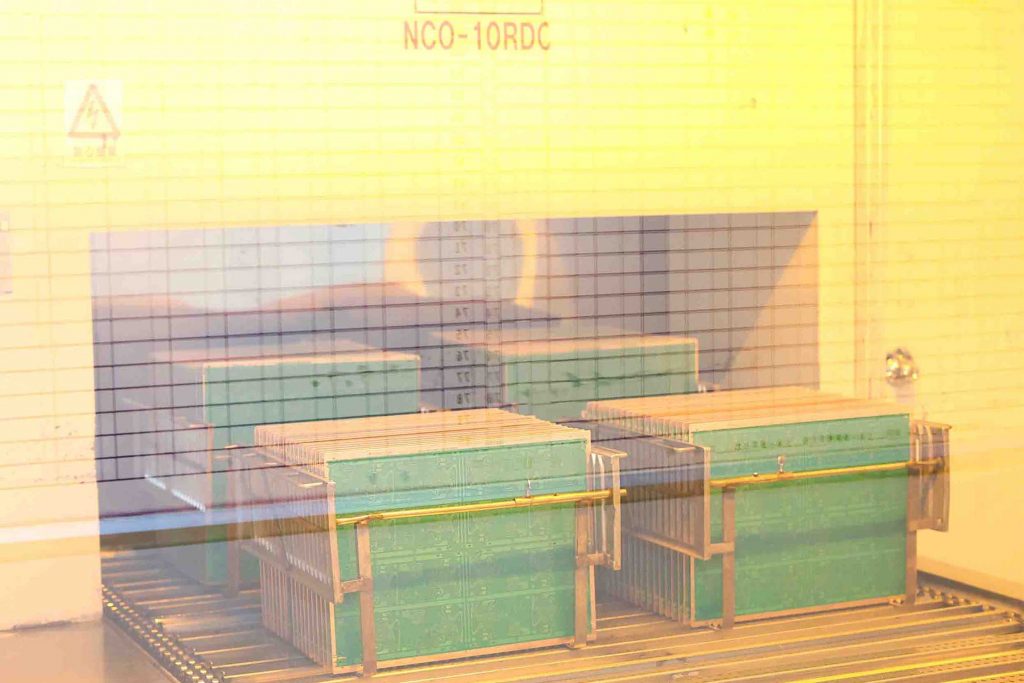

PCB factory display

Frequently Asked Questions

We can offer up to 24 to 40-layer boards with the highest degree of precision.

For multilayer PCBs, we can offer following finishes

*Electroless Nickel / Immersion Gold

*Silver

*Electroless Tin Lead

*Organic (OSP)

*Hard Gold (edge contact)

*Carbon

*Peelable

Our delivery schedule can range from 24 hours to 3 weeks depending on the project.

Single layer boards have just 1 layer and multilayer PCBs have multiple layers more than two.

At KING FIELD, we prioritize quality and efficiency as our core values. We understand the importance of timely execution for time-sensitive projects without compromising on production quality. Our commitment to speed encompasses rapid quotations, streamlined communication, personalized one-to-one service, and more. Rest assured that when you engage with us, our dedicated service begins irrespective of your final decision to choose our services or not.

To start PCB manufacturing, we would require various design files including Gerber Files, Bill of Materials (BOM) file, Assembly drawings, Preliminary files or any other special requirements file.