Turnkey PCB manufacturing offers a seamless, end-to-end solution for producing printed circuit boards. By integrating design, sourcing, assembly, and testing into one streamlined process, it eliminates the need to manage multiple vendors. This approach addresses common challenges in traditional PCB manufacturing, such as inconsistent quality and long lead times, which often exceed 8-12 weeks. With turnkey solutions, you benefit from faster turnaround times and a single point of contact, ensuring efficient communication and reduced project delays. As the demand for rapid delivery grows, turnkey PCB manufacturing has become essential for staying competitive in today’s fast-paced market.

Key Takeaways

- Turnkey PCB manufacturing makes production easier by handling everything.

- It includes design, parts sourcing, assembly, and testing in one place.

- This method saves time, cutting production by 30-50%.

- Businesses can quickly meet market needs with faster production.

- Combining services lowers costs and solves delivery problems.

- It is a good choice for startups and small businesses.

- Careful testing ensures products are high-quality and reliable.

- This improves customer trust and satisfaction.

- Turnkey providers can adjust to small or large production needs.

- They work well for prototypes or big production runs.

What Is Turnkey PCB Manufacturing?

Definition and Overview

Turnkey PCB manufacturing refers to a comprehensive approach where a single provider manages every stage of the printed circuit board (PCB) production process. This includes design, prototyping, component sourcing, assembly, and testing. By consolidating these steps under one roof, turnkey solutions eliminate the need for you to coordinate with multiple vendors. This streamlined process ensures faster production cycles, consistent quality, and reduced overhead costs. Whether you are a startup or an established business, turnkey PCB manufacturing simplifies complex workflows, allowing you to focus on innovation and product development.

Key Components of Turnkey PCB Manufacturing

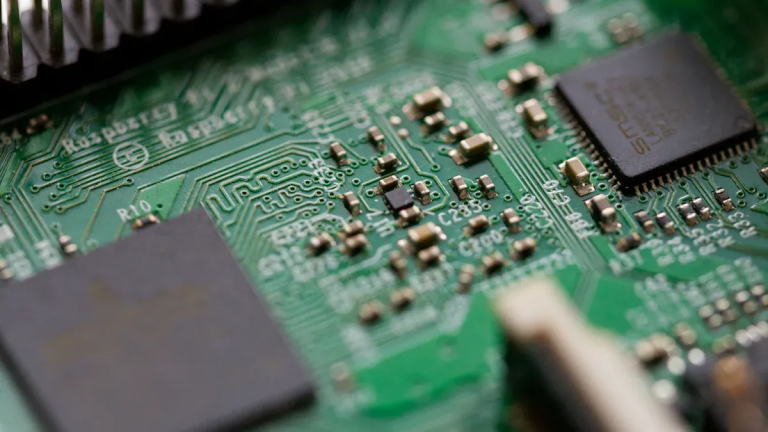

PCB Design and Prototyping

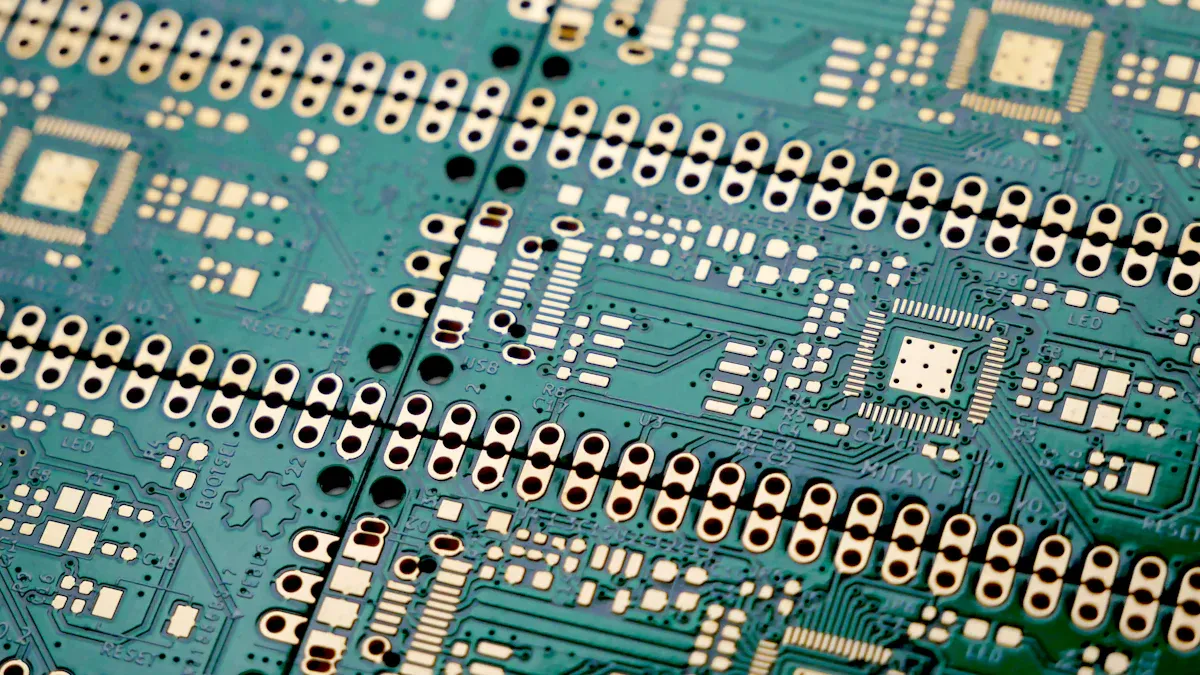

The process begins with creating a schematic and layout for your PCB. This stage involves translating your product’s requirements into a functional design. Prototyping follows, allowing you to test the design for performance and reliability before moving to full-scale production. Early prototyping helps identify and resolve potential issues, saving time and resources.

Component Sourcing and Procurement

Turnkey providers handle the sourcing of components required for your PCB. They leverage their supplier networks to secure high-quality parts at competitive prices. Bulk sourcing not only reduces costs but also ensures the availability of components, minimizing delays in production.

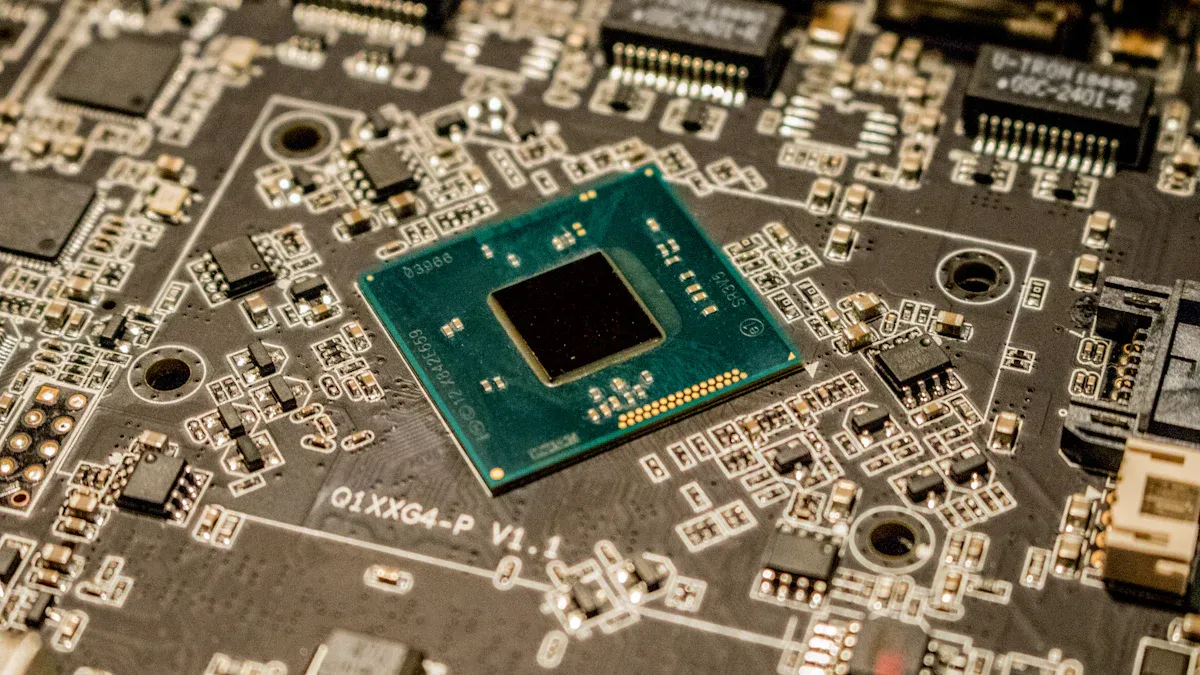

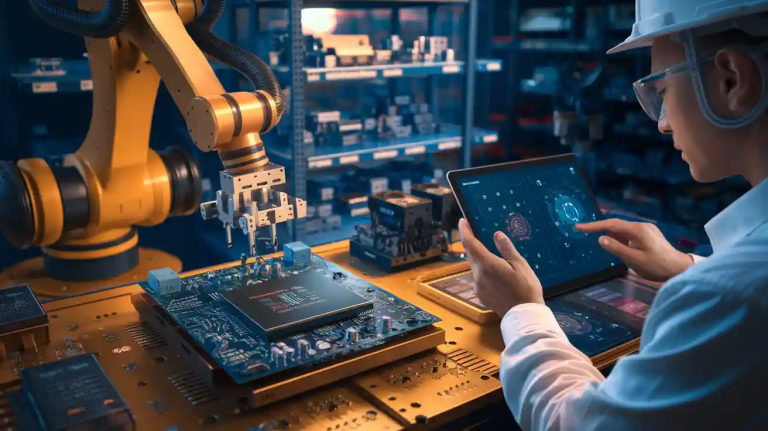

Turnkey PCB Assembly

In this stage, components are assembled onto the PCB using advanced techniques like surface-mount technology (SMT) or through-hole technology. Turnkey PCB assembly ensures precision and efficiency, reducing the risk of errors during production.

Testing and Quality Control

Rigorous testing is a cornerstone of turnkey PCB manufacturing. Providers conduct electrical tests, visual inspections, and in-circuit testing to verify the functionality and reliability of the PCB. This step ensures that the final product meets your specifications and industry standards.

How Turnkey PCB Manufacturing Works

The turnkey process follows a structured workflow to deliver high-quality PCBs efficiently. Here’s an overview of the steps involved:

- Initial Consultation: Discuss your requirements, including design specifications, budget, and timeline.

- Design and Prototyping: Develop the schematic and layout, then create prototypes for testing.

- Manufacturing: Fabricate the PCB by creating layers and etching conductive pathways.

- Assembly: Place components onto the PCB using SMT or through-hole technology.

- Testing and Quality Control: Perform rigorous testing to ensure functionality and reliability.

- Packaging and Delivery: Securely package the finished PCBs and ship them to you.

This end-to-end approach ensures that every stage of production is seamlessly integrated, reducing lead times and improving overall efficiency.

How Turnkey PCB Manufacturing Differs from Other Models

Turnkey vs. Contract Manufacturing

Scope of Services

Turnkey PCB manufacturing provides an all-inclusive service. The manufacturer handles every stage, from design to testing and delivery. This approach ensures that you only need to supply the design files and specifications. In contrast, contract manufacturing focuses on specific stages, such as assembly or testing. You must coordinate with multiple vendors to complete the production process.

Tip: Turnkey solutions save you time by consolidating all services under one provider, reducing the need for extensive project management.

Responsibility and Accountability

A turnkey provider assumes full responsibility for the entire production lifecycle. They manage design, material sourcing, assembly, and quality control. This ensures a seamless process and consistent quality. On the other hand, contract manufacturers rely on you to supply materials and manage other stages. This division of responsibility can lead to miscommunication and delays.

- Turnkey Manufacturing: The provider sources all materials and components, ensuring quality and availability.

- Contract Manufacturing: You supply materials, while the manufacturer focuses on labor and assembly.

Turnkey vs. Partial PCB Manufacturing

Integration of Processes

Turnkey PCB manufacturing integrates all processes, from sourcing to assembly, under one roof. This eliminates the need for you to manage multiple vendors. Partial PCB manufacturing, however, allows you to retain control over specific components. You may choose to source critical parts yourself while the provider handles the rest.

- Turnkey PCB Manufacturing: Streamlines the entire process, requiring only your design files and bill of materials.

- Partial PCB Manufacturing: Offers flexibility but requires more oversight and coordination on your part.

Vendor Management

Vendor management is simplified in turnkey PCB manufacturing. The provider handles all sourcing, assembly, and logistics. This reduces your workload and ensures faster turnaround times. In partial PCB manufacturing, you must manage some vendors yourself. This can lead to delays and increased complexity.

| Service Model | Partial Turn-Key PCB Assembly | Full Turn-Key PCB Assembly |

|---|---|---|

| Responsibilities | Client supplies some components | Provider sources all parts |

| Advantages | Greater control over components | Faster time-to-market |

| Challenges | Requires more oversight | Less control over sourcing |

Advantages of Turnkey PCB Manufacturing

Turnkey PCB manufacturing offers several advantages over other models:

- Integrated Efficiency: Combines all stages of production, reducing lead times.

- Cost-Effectiveness: Minimizes hidden costs and ensures long-term savings.

- Quality Assurance: Maintains consistent standards through comprehensive testing.

- Scalability: Adapts to your production needs, whether for prototypes or large-scale runs.

By choosing turnkey solutions, you benefit from a streamlined process that saves time and resources while delivering high-quality PCBs.

Benefits of Turnkey PCB Manufacturing

Cost Efficiency

Reduced Overhead Costs

Turnkey PCB manufacturing minimizes overhead expenses by consolidating all production stages under one provider. You no longer need to manage multiple vendors or handle logistics between them. This approach eliminates transportation and handling costs associated with shipping components between different facilities. Additionally, turnkey providers streamline operations, reducing redundancies and optimizing workflows. These efficiencies translate into significant cost savings for your business.

- Key Cost-Saving Opportunities:

- Reduced transportation and handling costs.

- Consolidated services and supplier management.

- Minimized administrative efforts and fixed costs.

Bulk Component Sourcing

Turnkey PCB assembly services leverage economies of scale to secure components at competitive prices. Providers maintain long-term relationships with suppliers, enabling them to negotiate better rates. Bulk purchasing not only ensures cost savings but also guarantees the availability of high-quality components. By sourcing materials early, turnkey providers mitigate risks associated with supply chain disruptions, ensuring your project stays on schedule.

Tip: Bulk sourcing through turnkey services reduces logistical challenges, saving you time and money on shipping and inventory management.

Streamlined Processes

Simplified Communication

Turnkey PCB manufacturing simplifies communication by providing a single point of contact for your project. Instead of coordinating with multiple vendors, you work directly with one provider who oversees the entire process. This reduces the chances of miscommunication and ensures that your requirements are clearly understood and implemented. A streamlined communication channel also allows for quicker resolution of any issues that may arise.

Faster Turnaround Times

By consolidating design, fabrication, and assembly processes, turnkey PCB manufacturing significantly reduces production timelines. Providers handle all stages in-house, eliminating delays caused by vendor coordination. This efficiency accelerates time-to-market, enabling you to respond quickly to market demands. Faster turnaround times give your business a competitive edge, especially in industries where speed is critical.

- Factors Enhancing Efficiency:

- Experienced providers with established workflows.

- Integrated processes that eliminate redundancies.

- Optimized project management from start to finish.

Quality Assurance

Consistent Standards Across Stages

Turnkey PCB manufacturing ensures consistent quality by adhering to industry standards like IPC certifications. These standards enhance the reliability and longevity of your PCBs, reducing the likelihood of malfunctions. By maintaining uniformity across all stages, turnkey providers deliver products that meet high-quality benchmarks and exceed customer expectations.

- Benefits of Consistent Standards:

- Uniformity in design, manufacturing, and testing.

- Enhanced product reliability and durability.

- Streamlined processes that minimize errors.

Comprehensive Testing Protocols

Turnkey providers implement rigorous testing protocols to verify the functionality and reliability of your PCBs. These include in-circuit testing (ICT), automated optical inspection (AOI), and functional testing. Each stage of testing ensures that your PCB meets performance specifications and industry standards. By identifying and addressing potential issues early, turnkey providers save you from costly rework and delays.

| Testing Method | Purpose |

|---|---|

| In-Circuit Testing (ICT) | Detects defects in the circuit. |

| Automated Optical Inspection | Ensures proper component placement and soldering. |

| Functional Testing | Verifies performance against specifications. |

Note: Comprehensive testing not only ensures quality but also boosts your confidence in the final product’s reliability.

Scalability and Flexibility

Adapting to Project Needs

Turnkey PCB manufacturing excels in adapting to projects of all sizes. Whether you need a small batch of prototypes or a full-scale production run, turnkey providers tailor their services to meet your specific requirements. This scalability ensures that you can transition seamlessly from initial design to mass production without needing to switch vendors.

Turnkey assembly services are designed to handle varying production volumes efficiently. Providers can adjust their operations to accommodate changes in your project scope, whether it involves increasing the number of units or modifying the design. This flexibility allows you to respond quickly to market demands or unexpected challenges. By partnering with a turnkey provider, you gain the ability to scale your production up or down as needed, ensuring your project remains on track.

Supporting Large-Scale Production

Turnkey PCB manufacturing supports large-scale production while maintaining high standards of quality. Providers employ advanced technologies and processes to ensure efficiency and reliability. For example, TechInnovate partnered with a leading turnkey PCB assembly manufacturer and achieved remarkable results:

- Comprehensive DFM (Design for Manufacturing) reviews ensured designs were optimized for production.

- Advanced SMT capabilities enabled the assembly of high-density boards with precision.

- Rigorous quality control processes reduced defect rates from 3.5% to less than 0.5%.

- Flexible production capacity allowed for a 300% increase in output without additional resource management.

These capabilities demonstrate how turnkey providers can handle large-scale production without compromising quality or efficiency. By reducing lead times from 10-12 weeks to just 4-5 weeks, they help you bring products to market faster. This scalability ensures that your business can grow without being constrained by manufacturing limitations.

Tip: Partnering with a turnkey provider not only simplifies your production process but also positions your business for long-term success in a competitive market.

Why Turnkey PCB Manufacturing Matters

Impact on Project Success

Meeting Deadlines

Turnkey PCB manufacturing plays a critical role in helping you meet project deadlines. By consolidating all production stages under one provider, it eliminates delays caused by transferring projects between multiple vendors. This streamlined approach reduces total production time by 30-50%, depending on the complexity and volume of your project. Managing a single turnkey provider simplifies communication, ensuring smoother execution and fewer misunderstandings.

- Key Benefits of Turnkey PCB Manufacturing for Deadlines:

- Faster lead times compared to traditional methods.

- Reduced delays from vendor coordination.

- Simplified project management with a single point of contact.

Ensuring Product Reliability

Turnkey providers prioritize quality at every stage of production, ensuring reliable printed circuit board assemblies. They follow stringent standards like IPC-A-610 and IPC-6012, conduct comprehensive testing, and implement rigorous quality control processes. These measures help identify defects early, ensuring your PCBs meet high-performance benchmarks.

| Quality Assurance Measures | Description |

|---|---|

| Quality Control Processes | High standards maintained throughout production. |

| Comprehensive Testing | Identifies defects and ensures consistent quality. |

Importance for Startups and Small Businesses

Lower Barriers to Entry

Turnkey PCB manufacturing offers startups and small businesses an accessible path to high-quality PCB production. It reduces the time and effort required for sourcing components and managing multiple vendors. This allows you to focus on core business activities, such as product development and marketing. Additionally, turnkey services provide competitive pricing, saving you money on shipping and logistics.

- Advantages for Startups:

- Professional-looking boards that impress investors.

- Early detection of design issues to prevent costly errors.

- Simplified budgeting with clear cost estimates.

Access to Expertise

Turnkey providers bring industry expertise to your project, ensuring best-in-class performance and reliability. They help you identify potential design flaws early, minimizing errors and improving product quality. With a single point of contact, you save time and energy, allowing you to focus on scaling your business.

- Expertise Benefits:

- High-quality products with expert soldering.

- Customization options without compromising cost efficiency.

- Enhanced investor confidence through professional-grade PCBs.

Role in Advancing Technology

Supporting Innovation

Turnkey PCB manufacturing fosters innovation by streamlining the production process. By managing all stages under one roof, it reduces lead times and allows you to focus on developing new technologies. This efficiency accelerates time-to-market, enabling quicker innovation cycles. Cost savings from consolidated services also free up resources for research and development.

- How Turnkey Supports Innovation:

- Shortened project timelines for faster market entry.

- Reliable quality control for dependable product development.

- Cost-effective solutions that allocate resources toward innovation.

Enabling Faster Product Development

Turnkey providers excel in rapid prototyping, which is essential for faster product development. They integrate new technologies seamlessly across the production process, allowing you to adapt quickly to changes in design or materials. With quick-turn PCB assembly, production times can shrink from weeks to just days, helping you stay ahead in competitive markets.

- Key Features for Faster Development:

- Agile adaptation to new designs and techniques.

- Comprehensive data utilization for process optimization.

- Rapid prototyping to address industry demands.

Tip: Partnering with a turnkey provider ensures your project benefits from streamlined processes, cost savings, and faster innovation cycles.

Turnkey PCB manufacturing simplifies the complex process of PCB production by integrating design, sourcing, assembly, and testing under one provider. This approach ensures seamless workflows, consistent quality, and faster delivery times. Its key components, such as prototyping, component procurement, and rigorous testing, create a reliable foundation for high-quality products.

Key Benefits for Businesses

- Cost Reduction: Consolidated services lower overhead and material costs.

- Convenient Prototyping: Rapid prototyping identifies design flaws early.

- Flexibility: Adapts to changes in design or production volumes.

- Efficient Resource Management: Frees you to focus on innovation.

- Risk Mitigation: Providers assume responsibility for assembly issues.

| Benefit | Description |

|---|---|

| Integrated Efficiency | Streamlines the entire PCB production process, from design to final assembly. |

| Time Savings | Faster turnaround times help meet tight market deadlines. |

| Quality Assurance | Consistent standards and comprehensive testing ensure reliable products. |

| Scalability | Easily adjusts to changing production needs, from prototypes to high-volume runs. |

By leveraging economies of scale, turnkey providers reduce costs and enhance operational efficiency. Their streamlined processes and consistent quality standards position your business to stay competitive in fast-paced markets. Whether you are a startup or an established company, turnkey PCB manufacturing offers the tools to innovate, scale, and succeed.

Tip: Partnering with a turnkey provider not only simplifies production but also strengthens your ability to deliver reliable, cutting-edge products.

FAQ

What is the difference between turnkey PCB manufacturing and traditional PCB production?

Turnkey PCB manufacturing integrates all stages of production under one provider. Traditional PCB production often requires you to manage multiple vendors for design, sourcing, assembly, and testing. Turnkey solutions streamline the process, saving time and reducing errors.

How does turnkey PCB manufacturing ensure quality?

Turnkey providers follow strict industry standards like IPC certifications. They conduct comprehensive testing, including in-circuit testing (ICT) and automated optical inspection (AOI). These measures ensure your PCBs meet performance requirements and maintain consistent quality across all production stages.

Can turnkey PCB manufacturing handle small production runs?

Yes, turnkey PCB manufacturing is highly scalable. Providers can efficiently manage small prototype runs or large-scale production. This flexibility allows you to test designs with minimal investment before committing to full-scale manufacturing.

How long does turnkey PCB manufacturing take?

Turnkey PCB manufacturing typically reduces lead times by 30-50% compared to traditional methods. Depending on your project’s complexity, production can take as little as 4-5 weeks, ensuring faster time-to-market for your products.

Is turnkey PCB manufacturing cost-effective for startups?

Absolutely. Turnkey solutions consolidate services, reducing overhead costs and logistical challenges. Bulk component sourcing and streamlined processes lower expenses, making it an ideal choice for startups looking to optimize budgets without compromising quality.

Tip: Partnering with a turnkey provider helps startups focus on innovation while leaving production complexities to the experts.