Choosing the right PCB manufacturers can make or break your project. A reliable PCB supplier board ensures your printed circuit board meets your specifications and performs flawlessly. Without the right partner, delays, quality issues, or miscommunication could derail your pcb manufacturing project.

By following structured tips, you can:

- Establish clear communication with your supplier.

- Provide detailed specifications for your printed circuit board needs.

- Collaborate effectively to ensure manufacturability.

- Test and validate your PCB for optimal performance.

- Build a long-term partnership for future projects.

When you choose a PCB manufacturer wisely, you set the foundation for success. Take control of your project by partnering with a supplier who aligns with your goals.

Key Takeaways

- Talk clearly with your PCB supplier to prevent confusion and succeed.

- Check the supplier’s certifications and quality checks for good PCBs.

- Make sure the supplier can make your specific PCB designs.

- Read customer reviews to see if the supplier is trustworthy.

- Find extra services like design help and testing to save time.

Assess the Quality of the PCB Supplier Board

Choosing a PCB supplier board with high-quality standards is essential for ensuring defect-free PCBs that meet your project requirements. To make an informed decision, you must evaluate certifications and quality control processes that reflect the supplier’s commitment to excellence.

Certifications to Look For

Certifications are a clear indicator of a PCB manufacturing company’s dedication to quality and compliance. Look for the following certifications when assessing a supplier:

- ISO Certifications: ISO 9001 ensures the supplier has a robust Quality Management System (QMS) in place, focusing on consistent delivery of high-quality PCBs. ISO 13485 and AS9100 are additional certifications for medical and aerospace applications.

- UL Certifications: These certifications guarantee the safety and compliance of printed circuit boards through rigorous testing.

- IPC Standards: IPC classifications, especially Class 3, demonstrate the supplier’s ability to produce high-quality PCBs for demanding industries like aerospace and military.

Adhering to these certifications ensures that the supplier meets high-quality standards, promotes reliability, and delivers defect-free PCBs.

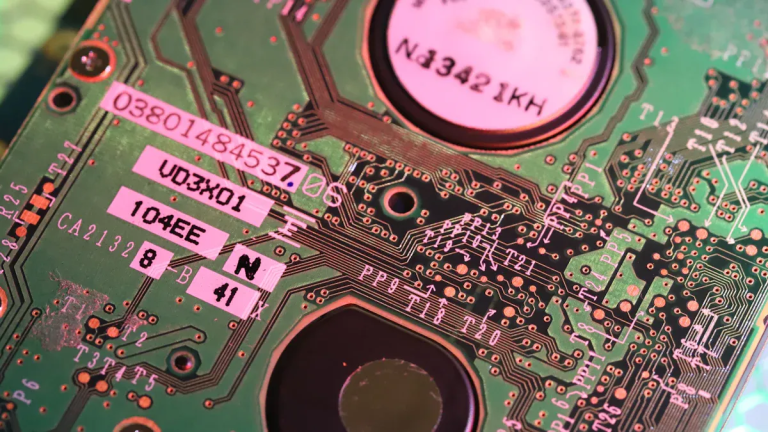

Quality Control Processes

A supplier’s quality control processes play a pivotal role in delivering high-quality PCBs. Top PCB manufacturing companies implement comprehensive inspection and testing capabilities to maintain consistency and reliability.

Testing Methods (e.g., AOI, X-ray Inspection)

Effective quality control begins with advanced testing methods. Automated Optical Inspection (AOI) systems detect defects in real-time during assembly, while X-ray inspections identify hidden issues like solder joint problems. These methods ensure thorough inspection at every stage of production.

Consistency in Delivering High-Quality Products

Consistency is key to quality assurance. Suppliers with IPC-certified technicians and documented process controls maintain uniformity in production. Regular assembly checks and functional testing further guarantee defect-free PCBs. A supplier with robust inspection and testing capabilities ensures your PCB performs flawlessly in its intended application.

By prioritizing certifications and quality control processes, you can confidently choose a PCB supplier board that aligns with your project goals and delivers high-quality PCBs every time.

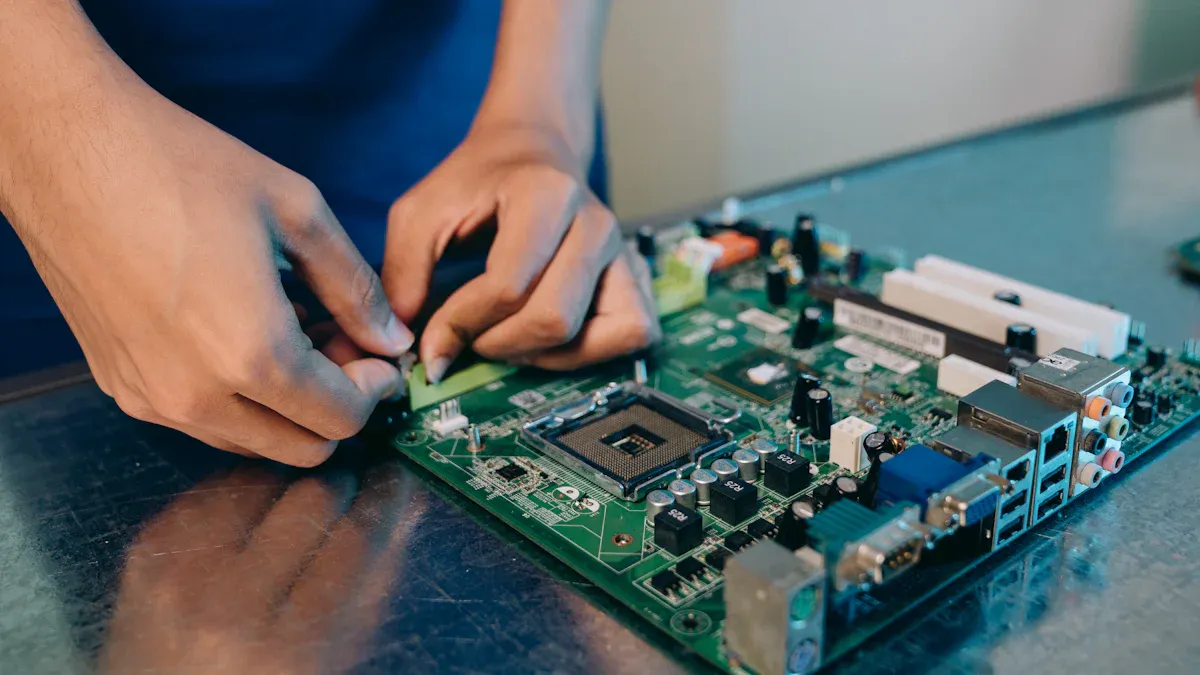

Evaluate the Manufacturing Capabilities of the PCB Supplier

When choosing a PCB supplier, their manufacturing capabilities can significantly impact your project’s success. A supplier with robust technical expertise and production capacity ensures your PCBs meet your design and volume requirements.

Technical Expertise

Handling Complex PCB Designs (e.g., multilayer, HDI)

Not all suppliers can handle intricate PCB designs like multilayer or HDI boards. You need a partner with proven technical expertise to manage these complexities. Look for the following indicators:

- Technical Depth: Ensure the supplier has experience with advanced PCB designs.

- Technology Alignment: Verify their equipment and processes match your project’s needs.

- Certifications and Standards: Check for ISO 9001 and IPC-A-610 certifications to ensure quality.

- Equipment and Process Capabilities: Confirm they use advanced tools like SMT placement machines and AOI systems.

- Quality Assurance Rigor: Ask about their inspection protocols and traceability systems.

- Engineering Expertise: Collaborate with their engineers early for design-for-manufacturing (DFM) support.

A supplier with these capabilities can handle even the most demanding PCB designs, ensuring your project stays on track.

Support for Various Materials and Finishes

Your project may require specific materials or finishes, such as FR4, aluminum, or gold plating. A capable supplier offers a wide range of options to meet your needs. Their expertise in handling diverse materials ensures your PCB performs optimally in its intended application.

Production Capacity

Scalability for Prototyping and Mass Production

A reliable supplier should scale production to match your requirements, whether you need a prototype or mass production. Here’s what you should expect:

- Prototyping: Quick turnaround for small batches to test your design.

- Mass Production: Capacity to produce thousands or even millions of PCBs.

| Feature | Details |

|---|---|

| Order Size | No limits per order; supports small to large volumes. |

| Daily Production Rate | 600–800 boards per day. |

| Panel Sizes Available | 12×18, 18×24, and 21×24. |

This scalability ensures your supplier can grow with your project.

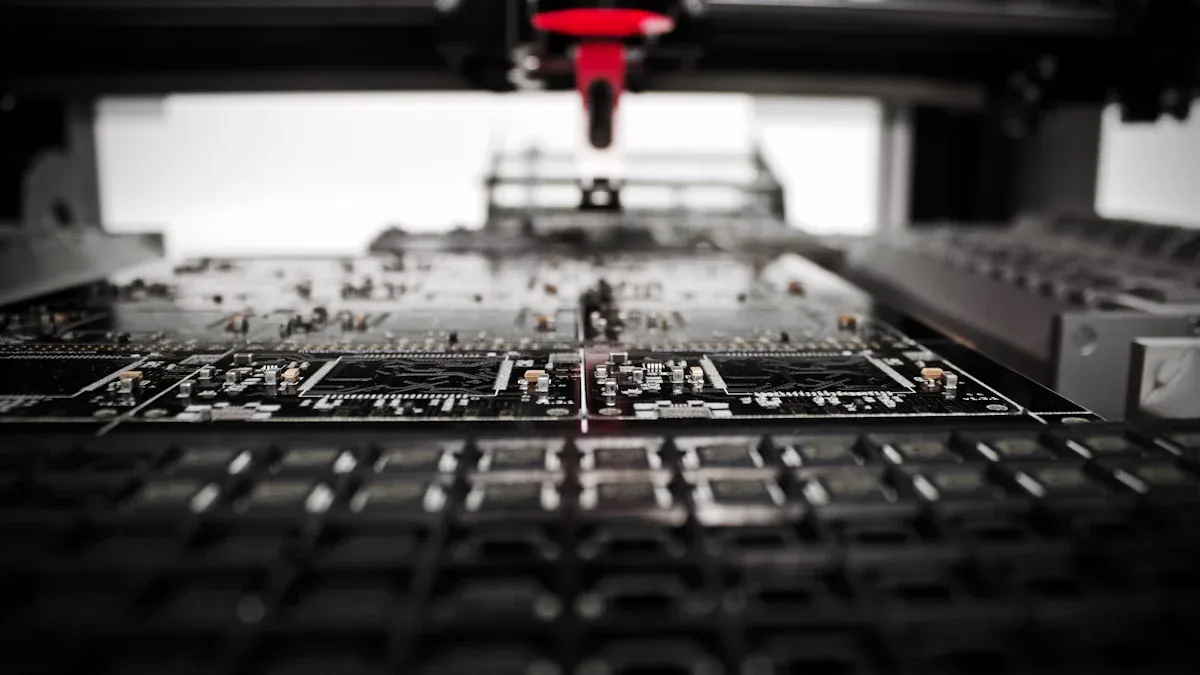

Advanced Equipment and Technology

Modern PCB manufacturing relies on cutting-edge equipment. A supplier with advanced tools ensures precision and efficiency. Key technologies include:

- Automated Optical Inspection (AOI)

- Surface Mount Technology (SMT) Equipment

- Multi-layer Presses

- Computer Numerical Control (CNC) Equipment

- Surface Finishing Technology

These tools enhance production quality and reduce errors, giving you confidence in your supplier’s capabilities.

By evaluating a supplier’s technical expertise and production capacity, you can ensure they have the manufacturing capabilities to meet your project’s demands.

Consider the Experience and Reputation of the Supplier

When selecting the right PCB manufacturers, the supplier’s experience and industry reputation play a pivotal role in ensuring your project’s success. A well-established PCB manufacturing company with a proven track record can provide the reliability and quality you need.

Track Record and Industry Expertise

Years in Business and Portfolio of Past Projects

A supplier with years of experience in the PCB industry demonstrates stability and expertise. Look for manufacturers who have successfully completed projects similar to yours. Their portfolio should showcase a variety of PCB designs, including complex multilayer boards and high-density interconnects (HDI). This breadth of experience ensures they can handle your unique requirements with confidence.

Case Studies Demonstrating Success

Case studies offer valuable insights into a supplier’s capabilities. They highlight real-world examples of how the manufacturer has delivered high-quality PCBs for demanding applications. These success stories can reassure you that the supplier has the technical expertise and problem-solving skills to meet your expectations.

Customer Reviews and Testimonials

Identifying Positive Feedback Trends

Customer reviews and testimonials provide a window into a supplier’s reputation. Look for consistent praise in areas like communication, delivery reliability, and product quality. Positive feedback about their ability to adapt to changing project requirements or provide excellent customer support is a strong indicator of a reliable partner.

Addressing Red Flags in Negative Reviews

Negative reviews can reveal potential issues. Pay attention to recurring complaints about delays, poor communication, or inconsistent quality. If a supplier has addressed these concerns transparently and resolved them effectively, it shows their commitment to improvement. However, unresolved issues may signal a lack of reliability.

Tip: Choose a PCB manufacturing company with a strong reputation for quality, flexibility, and customer support. This ensures your project stays on track and meets your expectations.

By evaluating a supplier’s experience and industry reputation, you can make an informed decision. A trusted partner with a solid track record and positive customer feedback will help you achieve your project goals with confidence.

Analyze Lead Times and Delivery Reliability

Timely delivery is critical to the success of your project. A PCB supplier with dependable lead times and delivery performance ensures you meet deadlines without compromising quality. Here’s how you can evaluate these factors effectively.

Turnaround Times

Prototyping vs. Full Production Lead Times

Understanding the difference between prototyping and full production lead times helps you plan better. Prototyping often requires faster turnaround to test designs quickly.

- Domestic suppliers can deliver prototypes in as little as 24-48 hours for quick-turn services, though this may come at a higher cost.

- Offshore manufacturers typically offer more economical options, with lead times ranging from 3-7 days.

For full production, lead times may extend depending on order size and complexity. Always confirm timelines with your supplier to avoid delays.

Flexibility for Urgent Orders

Urgent orders can arise unexpectedly. A supplier’s ability to handle these depends on several factors:

- Effective communication ensures your priorities are understood. Regular meetings can align expectations.

- Workflow optimization, such as implementing a first-in, first-out (FIFO) system, allows suppliers to manage urgent orders without disrupting regular production.

- Managing costs like storage and shipping efficiently helps prioritize urgent needs.

Choose a supplier who demonstrates flexibility and a proactive approach to urgent requests.

Delivery Performance

On-Time Delivery Rates

On-time delivery rates (OTD) are a key metric for evaluating a supplier’s reliability. This metric measures the percentage of orders delivered on schedule. Consistently high OTD rates prevent production delays and keep your project on track.

Reliable Logistics Partnerships

Strong logistics partnerships enhance delivery reliability. Suppliers with established networks can adapt to unforeseen challenges, ensuring your PCBs arrive as planned. Look for those who prioritize consistency and flexibility in their delivery schedules.

| Metric | Description |

|---|---|

| On-Time Delivery Rate (OTD) | Measures the percentage of orders delivered on time, calculated as (Number of on-time deliveries / Total deliveries) x 100. |

| Consistency | Ensures reliable delivery schedules to prevent production delays and meet customer demand. |

| Flexibility | Ability of suppliers to adapt to changes in specifications or demand, crucial in dynamic markets. |

| Lead Time | The time between order placement and delivery, with shorter times aiding in production planning. |

By analyzing lead times and delivery performance, you can select a PCB supplier who aligns with your project’s timeline and ensures reliability throughout the process.

Review Pricing and Transparency When You Choose a PCB Manufacturer

When you choose a PCB manufacturer, understanding their pricing structures and transparency is crucial. A clear breakdown of costs and open communication ensures you avoid unexpected expenses and stay within budget.

Pricing Structures

Cost Breakdown (e.g., materials, labor, shipping)

PCB pricing depends on several factors, including materials, labor, and shipping. Here’s a quick overview of typical price ranges:

| Specification | Price Range (USD) | Notes |

|---|---|---|

| Single Layer PCB (100mm x 100mm) | $2 – $5 | Varies with quantity |

| Double Layer PCB (100mm x 100mm) | $5 – $10 | Varies with quantity and thickness |

| 4 Layer PCB (100mm x 100mm) | $10 – $20 | Price increases with complexity |

| Single Layer PCB (200mm x 200mm) | $5 – $10 | Varies with quantity |

| Double Layer PCB (200mm x 200mm) | $10 – $20 | Varies with quantity and thickness |

| 4 Layer PCB (200mm x 200mm) | $20 – $40 | Price increases with complexity |

Factors like circuit complexity, PCB size, and layer count also influence costs. For example:

- Circuit Complexity: More intricate designs require additional components, increasing expenses.

- PCB Size: Larger boards demand more materials and higher shipping fees.

- Layer Count: Adding layers raises manufacturing complexity and costs.

Understanding these elements helps you plan your budget effectively.

Identifying Hidden Fees

Hidden fees can inflate your costs unexpectedly. Watch out for these common charges:

| Fee Type | Description | Cost Impact | Mitigation Strategies |

|---|---|---|---|

| Panelization Fee | Charges for combining multiple PCB designs onto a single panel. | Significant for small quantities or designs. | Panelize designs yourself or reduce separate designs. |

| Multiple Design Fee | Applied when different PCB designs are included in one order. | Adds per-design charges. | Consolidate designs or order separately to minimize fees. |

| Testing Fees | Costs for electrical testing services like Flying Probe or Bed of Nails. | High for complex PCBs or large runs. | Test prototypes thoroughly to avoid issues in production. |

| Special Material Fees | Extra charges for non-standard materials like aluminum or high-Tg FR4. | Increases based on material availability. | Stick to standard FR4 when possible. |

| Stencil Fee | Costs for custom stencils used in solder paste application. | Mandatory for SMT assembly. | Use a single stencil for boards with similar components. |

By identifying these fees early, you can negotiate better terms or adjust your design to minimize unnecessary costs.

Transparent Communication

Clear Quotes and Invoices

A trustworthy supplier provides detailed quotes and invoices. These documents should clearly outline all costs, including materials, labor, shipping, and any additional fees. Transparency in pricing builds trust and helps you avoid surprises.

Open Discussions on Pricing Adjustments

Open communication is key to managing costs effectively. A reliable supplier will discuss pricing adjustments with you, whether due to design changes, material upgrades, or order volume increases. This collaborative approach ensures you stay informed and in control of your budget.

Tip: Always ask for a comprehensive cost breakdown and clarify any ambiguous charges before finalizing your order.

By reviewing pricing structures and ensuring transparent communication, you can choose a PCB manufacturer who aligns with your financial goals while maintaining quality and reliability.

Examine Customer Service and Communication with Your PCB Assembly Partner

When working with pcb assembly companies, customer service and communication can make or break your project. A reliable pcb assembly partner ensures smooth collaboration, quick resolutions, and a seamless experience. Let’s explore how responsiveness and problem-solving skills can help you choose the right partner.

Responsiveness

Speed of Replies to Inquiries

Timely responses are crucial when you’re managing tight deadlines. A pcb assembly partner who replies quickly to your inquiries shows they value your time. Whether you’re asking about pricing, lead times, or technical details, their ability to provide prompt answers keeps your project on track. Delays in communication can lead to missed deadlines and unnecessary stress.

Availability of Support Channels (e.g., email, phone, chat)

Effective communication depends on accessible support channels. Look for pcb assembly companies that offer multiple ways to connect, such as email, phone, and live chat. This variety ensures you can reach them in the way that’s most convenient for you. A partner with 24/7 support availability demonstrates their commitment to your success, especially when urgent issues arise.

Problem-Solving Skills

Handling Complaints or Issues

Every project encounters challenges, but how your pcb assembly partner handles them sets the tone for your collaboration. The best pcb assembly companies use structured approaches like the Kepner-Tregoe methodology. This method involves analyzing the situation, identifying root causes, and evaluating potential solutions. By addressing problems systematically, they avoid quick fixes and deliver lasting results.

Collaborating on Solutions

Collaboration is key to resolving issues effectively. Top pcb assembly companies use tools like brainstorming and prioritization matrices to involve you in the problem-solving process. They also rely on techniques like the 5 Ws and H (Who, What, Where, When, Why, and How) to gather comprehensive information. This approach ensures they fully understand your concerns and develop solutions tailored to your needs.

Tip: Choose a pcb assembly partner who prioritizes effective communication and excels in problem-solving. Their responsiveness and collaborative approach will ensure your project runs smoothly from start to finish.

Look for Value-Added Services from Your PCB Supplier

When selecting a PCB supplier, value-added services can make a significant difference in your overall experience. These services not only enhance the quality of your project but also save you time and resources. Let’s explore the additional offerings and long-term benefits you should look for in a supplier.

Additional Offerings

Design Assistance and Prototyping Support

A supplier that offers design assistance can help you refine your PCB layout for optimal performance. Their expertise ensures your design is manufacturable and meets industry standards. Prototyping support is equally important. Quick prototyping services allow you to test and validate your design before full-scale production. This reduces the risk of costly errors and ensures your project stays on track.

Assembly Services and Testing

Comprehensive assembly services streamline your production process by integrating component placement and soldering into one solution. Testing services, such as functional testing and in-circuit testing, verify that your PCB operates as intended. These services eliminate the need for third-party testing, saving you time and ensuring quality control.

| Value-Added Service | Description |

|---|---|

| Technical application engineering support | Assistance in selecting the right sensors for specific needs, ensuring appropriate solutions. |

| 24/7 technical emergency hotline | Immediate troubleshooting support for urgent testing or monitoring needs at any time. |

| Best-in-class warranty and ‘no-risk’ policy | Assurance of repair, replacement, or refund if customers are not satisfied with their order. |

| Customer feedback mechanisms | Encouragement for customers to provide feedback to improve services and correct issues. |

Long-Term Partnership Potential

Discounts for Repeat Customers

Building a long-term relationship with your supplier often comes with financial perks. Many suppliers offer discounts for repeat customers, reducing your overall costs. These savings can be reinvested into future projects, giving you a competitive edge.

Support for Future Projects

A reliable supplier becomes a valuable partner for your future endeavors. Long-term partnerships foster better collaboration and faster turnaround times. Suppliers committed to quality standards ensure consistent results. They also provide advanced customization options and robust compliance with safety regulations. This level of support helps you innovate and scale your projects with confidence.

- Benefits of long-term partnerships include:

- Faster turnaround and shorter lead times

- Intellectual property protection

- Supply chain stability and risk mitigation

- Advanced technological innovation

Tip: Choose a supplier who offers value-added services and demonstrates a commitment to long-term collaboration. These qualities ensure your projects succeed today and in the future.

Choosing the right PCB supplier board is a critical step in ensuring your project’s success. By focusing on quality standards, manufacturing capabilities, customer service, pricing, lead times, and environmental responsibility, you can make an informed decision. Prioritize suppliers who demonstrate reliability, offer value-added services, and align with your long-term goals.

Remember, the best supplier is not just about the lowest price but the overall value they bring to your project. Take the time to assess their certifications, production capabilities, and customer support. With the right partner, you can confidently bring your PCB designs to life and achieve outstanding results.

Pro Tip: Apply these seven tips today to find a supplier who meets your needs and helps you stay ahead in your industry.

FAQ

What is the most important factor when choosing a PCB supplier?

You should prioritize quality above all else. A supplier with strong certifications, advanced testing methods, and consistent delivery ensures your PCB performs reliably. This guarantees your project stays on track and meets your expectations.

How can I ensure my PCB supplier meets deadlines?

Ask about their on-time delivery rates and logistics partnerships. Reliable suppliers provide clear timelines and adapt to urgent requests. Their ability to meet deadlines ensures your project progresses without delays.

Why are value-added services important in PCB manufacturing?

Value-added services like design assistance and testing save you time and resources. These offerings enhance your PCB’s quality and ensure it meets industry standards. They also simplify your project by reducing the need for third-party services.

How do I avoid hidden fees when working with a PCB supplier?

Request a detailed cost breakdown upfront. Clarify charges for materials, labor, and additional services. Transparent communication helps you identify and eliminate unnecessary expenses, keeping your project within budget.

Can I trust online reviews when selecting a PCB supplier?

Yes, but analyze trends in feedback. Consistent positive reviews about quality and communication indicate reliability. Address recurring negative comments directly with the supplier to assess their commitment to improvement.