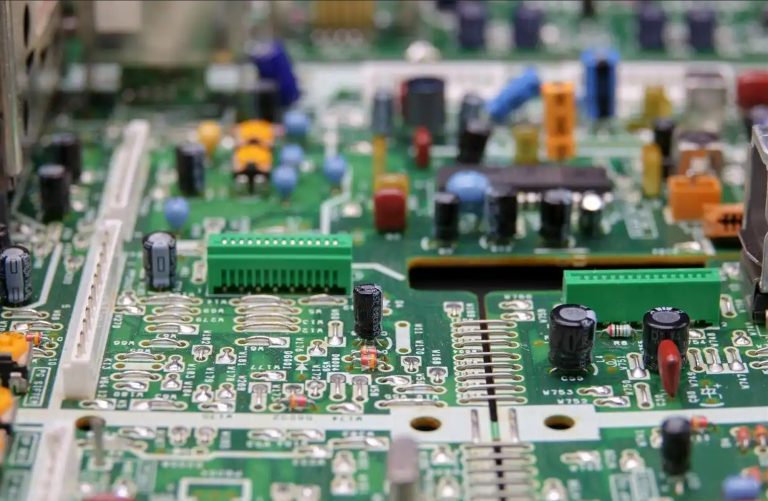

Medical PCBA, or Printed Circuit Board Assembly, is key to modern medical devices. It connects important electronic parts, helping devices do tasks like checking vital signs, giving treatments, and supporting life-saving systems.

Medical PCBA powers devices like pacemakers, glucose monitors, and neurostimulators. These devices make patients more comfortable by being less invasive. They give real-time data for better diagnoses and help people in areas with less healthcare. From ventilators to infusion pumps, medical PCBA helps healthcare improve with safe and accurate patient care.

Key Takeaways

- Medical PCBA is important for wearable and implantable devices. It connects electronic parts to help improve patient care.

- Wearable devices, like fitness trackers and glucose monitors, use Medical PCBA. These devices give real-time health data and make healthcare easier.

- Implantable devices, such as pacemakers and cochlear implants, depend on Medical PCBA. It ensures these devices work safely and reliably inside the body.

- Small and bendable designs in Medical PCBA make devices more comfortable. This helps them fit easily into everyday life.

- Following strict rules like ISO 13485 makes Medical PCBA safe. It helps create high-quality and dependable medical devices.

Applications of Medical PCBA in Medical Devices

Medical PCBA is crucial for wearable and implantable medical devices. These uses show how circuit boards help create better healthcare tools.

Wearable Devices

Wearable devices have changed healthcare by tracking health in real-time. Medical PCBs keep these devices small, effective, and dependable.

Fitness Trackers and Smartwatches

Fitness trackers and smartwatches use PCBA to track heart rate, steps, and sleep. They help you stay healthy by giving useful health tips. Medical PCBA ensures accurate tracking and easy connection to other gadgets.

Continuous Glucose Monitors

Continuous glucose monitors (CGMs) are helpful for people with diabetes. Medical PCBs let these devices check glucose levels and send data to phones. This reduces finger pricks and makes diabetes care easier.

Remote Patient Monitoring Devices

Remote patient monitors let doctors check your health from far away. Medical PCBs make these devices work well and send data smoothly. This is especially helpful for people in areas with less healthcare.

Did you know? The wearable device market using medical PCBA was worth $61.30 billion in 2023. It is growing at 18% yearly. Over 80% of Americans now own wearable devices, showing their popularity.

| Statistic | Value |

|---|---|

| Global market value in 2023 | $61.30 billion |

| Expected CAGR for medical wearables | 18% |

| Percentage of U.S. consumers owning wearables | Over 80% |

| Global market value in 2022 | $33.5 billion |

| Expected market value by 2025 | $74.2 billion |

| Expected CAGR for IoT in wearables | 14.6% |

Implantable Devices

Implantable devices depend on medical PCBA to work safely inside the body. These devices must be very safe and reliable.

Pacemakers and Defibrillators

Pacemakers and defibrillators use PCBs to control heartbeats and give shocks. Their small size allows them to be implanted with little discomfort.

Cochlear Implants

Cochlear implants help people with hearing loss hear better. Medical PCBs process sounds and send signals to the hearing nerve.

Neurostimulators and Drug Delivery Systems

Neurostimulators and drug delivery systems help people with chronic illnesses. Medical PCBs make sure these devices work accurately, sending signals or medicine when needed.

Medical PCBA in wearable and implantable devices shows its role in healthcare. These tools improve patient health and make care better.

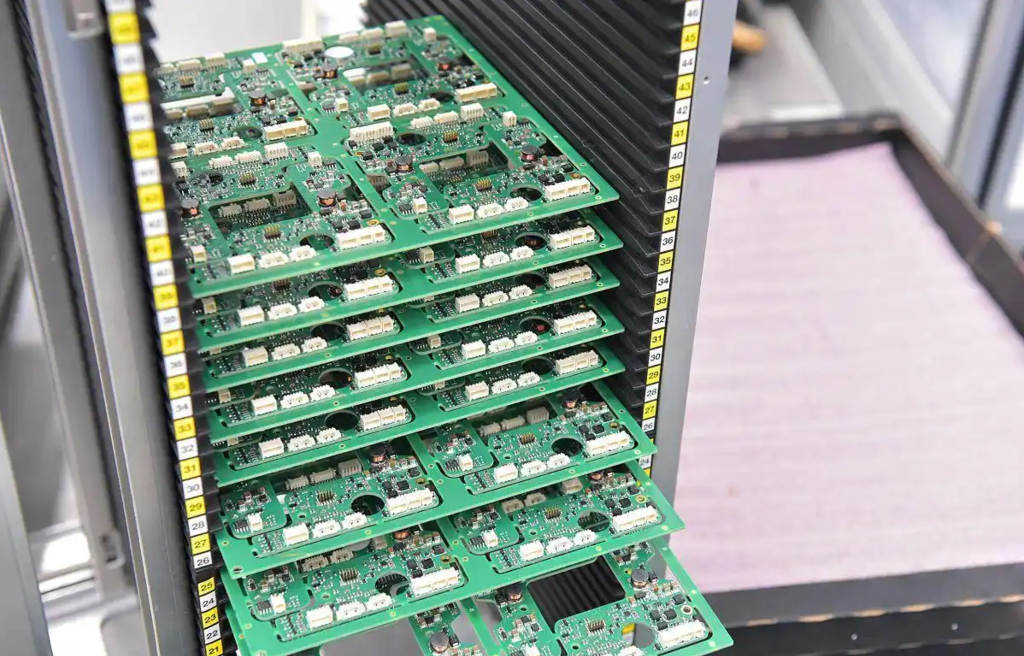

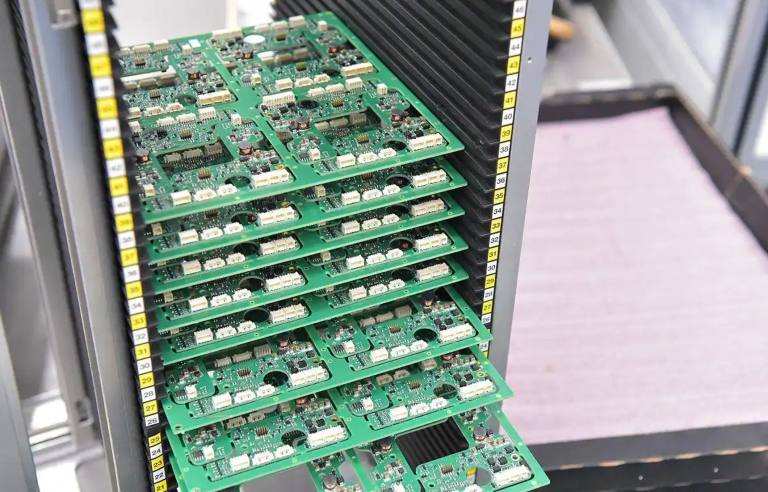

Design and Manufacturing Considerations for Medical PCBA

Miniaturization and Compact Design

Why smaller devices matter in wearables and implantables

Small devices are important for comfort and ease of use. Tiny implantable devices, like pacemakers, fit easily in the body. Wearable gadgets, like fitness trackers, are lighter and less bulky. PCB assembly helps shrink devices by combining parts into one small unit. This keeps devices portable and efficient without losing functionality.

Problems with making small designs

Making small designs can be tricky. Parts must be placed carefully to avoid problems. Multi-layer boards are often needed for complex wiring, which is harder to make. Small devices can overheat, so heat sinks and smart layouts help manage heat. Parts also need to handle moisture and temperature changes to stay reliable.

Flexibility and Durability

Flexible PCBAs for wearable gadgets

Wearable gadgets need to bend and move with users. Flexible PCBs use materials that bend but still work well. This makes devices like smartwatches and fitness trackers last longer. Flexible designs also allow cool shapes, making wearables more comfy and stylish.

Making implantable devices strong and reliable

Implantable devices must be very strong to work inside the body. They need to handle body fluids and temperature changes for years. Backup systems ensure they work even if one part fails. Safety tests check that these devices meet strict medical rules. This ensures they stay safe and reliable over time.

Biocompatibility and Material Selection

Why biocompatible materials are needed for implantables

Implantable devices need materials that are safe for the body. PCB parts must not cause irritation or rejection. Special coatings and materials are chosen to work well with human tissue. This helps devices like cochlear implants fit naturally in the body.

Stopping bad reactions in the body

Bad reactions can make medical devices unsafe. To prevent this, makers use non-toxic, corrosion-resistant materials. They follow strict rules like ISO 13485 to meet medical standards. Careful material choices keep patients safe and devices dependable.

Regulatory and Safety Standards for Medical PCBA

ISO 13485 Compliance

What is ISO 13485?

ISO 13485 is a global rule for medical device quality. It makes sure companies follow strict steps to make safe products. This rule focuses on managing risks, tracking parts, and meeting laws. By following ISO 13485, you know medical tools are high-quality and trustworthy.

Why is compliance important?

Following ISO 13485 is key to making safe devices. It lowers risks by requiring careful tests and records at every step. For companies, it builds trust and allows selling in strict markets. For you, it means the devices you use are safe and work well.

IEC 60601 Standards

Keeping medical devices safe

IEC 60601 sets rules for safe medical electrical tools. Its main goal is to protect people from shocks or burns. This rule ensures devices work safely in different situations, giving you confidence in using them.

| Aspect | Description |

|---|---|

| Standards Overview | IEC 60601 gives safety and performance rules for medical electrical tools. |

| Safety Goals | It aims to keep patients safe from shocks or burns. |

| Framework Consistency | It provides clear safety rules for many medical electrical tools. |

Special rules for wearable and implantable devices

Wearable and implantable devices need extra safety because they touch the body. IEC 60601 adds rules like better insulation and fail-safe systems. These rules make sure your device works safely and reliably.

FDA and Other Regional Regulations

How does the FDA approve devices?

The FDA checks medical devices in the U.S. before they are sold. This includes lab tests, human trials, and checks after selling. For you, this means FDA-approved devices are tested for safety and quality.

Different rules in other places

Medical device rules change in different countries. The U.S. uses FDA rules, while Europe uses CE marking, and Japan has PMDA. Companies must follow these rules to sell worldwide. For you, this means devices meet safety rules wherever you live.

Benefits of Medical PCBA in Healthcare Devices

Better Patient Monitoring and Care

Collecting and using real-time health data

Medical PCBs help devices track health in real-time. These devices gather and send important health data nonstop. For example:

- IoT devices let doctors check patients at home, reducing trips.

- Real-time data helps doctors quickly change treatments for better care.

- Dashboards with medical PCBs let doctors watch many patients easily.

This makes sure you get fast and accurate care, even far away. IoT and medical PCBs make wearable devices more useful in healthcare today.

Helping patients with early problem detection

Finding health problems early makes treatments work better. Medical PCBs make diagnostic devices reliable for spotting issues on time. By giving constant and accurate data, these devices help doctors act early. This lowers risks and improves your health outcomes.

More Reliable and Long-lasting Devices

Why reliable PCBAs matter in medical tools

Medical tools must work without failing. Good medical PCBs keep devices like pacemakers working for a long time. Following rules like ISO 13485 ensures these PCBs are high-quality. This is key for life-saving devices to work well.

Making implantable devices last longer

Medical PCBs are built to handle tough conditions. They resist body fluids and temperature changes. Tests under stress make sure they stay strong. For example:

- Stress tests copy real-life conditions.

- Data from tests checks how well they work.

- Results predict how long they will last.

These steps make sure implantable devices work for years, giving you reliable care.

Progress in Personalized Medicine

How PCBAs help create custom treatments

Medical PCBs are important for personalized medicine. They let devices collect and use data just for you. Small sensors in PCBs gather key details for accurate care.

Using AI and IoT for personal healthcare

AI and IoT with medical PCBs are changing healthcare. IoT shares data instantly, and AI improves diagnosis and treatment plans.

IoT devices monitor health and allow remote care, fitting your needs.

This teamwork makes medical devices better and opens doors to new healthcare ideas.

Medical PCBA is vital for wearable and implantable devices. These small, strong circuit boards improve medical tools. They help with accurate tests and better treatments. Real-time tracking and IoT features allow personalized care. This improves health results for patients.

New PCBA designs create safer and better medical devices. Following strict rules ensures these devices are safe and high-quality. This protects patients and builds trust in healthcare systems.

| Evidence Type | Description |

|---|---|

| Better Performance | PCBs make devices more reliable for patient care. |

| Safety Standards | Built to meet strict rules, keeping patients safe. |

| Clear Signals | Stable signals help with accurate health checks. |

| Custom Designs | Special PCBs help create new medical tools. |

| Smaller Devices | Tiny designs make devices easier and more comfy to use. |

| IoT Features | Real-time tracking and remote care through IoT connections. |

- Small sensors in PCBs collect important health data for tracking.

- Custom designs improve how devices work and inspire new ideas.

- Cloud storage keeps health data in one place for better care.

Medical PCBA keeps changing healthcare by focusing on safety, ease, and personal care.

FAQ

What does PCBA do in medical devices?

PCBA is like the brain of medical devices. It connects and powers parts to work together. It helps process data, ensures smooth performance, and links device components. This is why it’s vital for tools like imaging machines and monitors.

Why is making PCBA smaller important?

Smaller PCBAs make devices lighter and easier to use. Tiny PCBAs help wearables stay hidden and implantables fit inside the body. This makes devices more comfortable and better for patients.

How does PCBA make medical devices more reliable?

PCBA uses strong materials and smart building methods. This helps devices like pacemakers work well in tough conditions. It keeps them running safely for important healthcare tasks.

Do medical imaging devices use PCBAs?

Yes, PCBAs are key in imaging devices. They handle tricky data and create clear pictures. This helps doctors find problems and treat patients better.

Why is PCBA important for medical monitors?

PCBA helps monitors collect and send health data quickly. It keeps these devices working well and gives accurate info to doctors and patients. This leads to smarter choices and better care.