Finding good industrial control board services can be tough. The market is growing from $11 billion in 2023 to $18 billion by 2032. Many industries like factories, energy, and medicine need these services. This growth shows how automation helps work faster and with fewer mistakes. But picking the right company takes research, checking their work, and clear talks.

Focus on saving energy and being eco-friendly has led to new ideas in control boards. These boards help save power and follow green rules.

Experienced companies give custom solutions to improve safety and work quality. Their skills lower risks and create systems that fit your needs.

Key Takeaways

- Look into companies carefully to find ones that know your industry.

- Check for certifications like ISO 9001 to confirm safety and quality.

- Review past work and customer feedback to see if they are reliable.

- Compare services and prices, focusing on what gives the best value.

- Pick companies that provide support to keep your systems working well.

Understanding Industrial Control Board Services

What Are Industrial Control Boards?

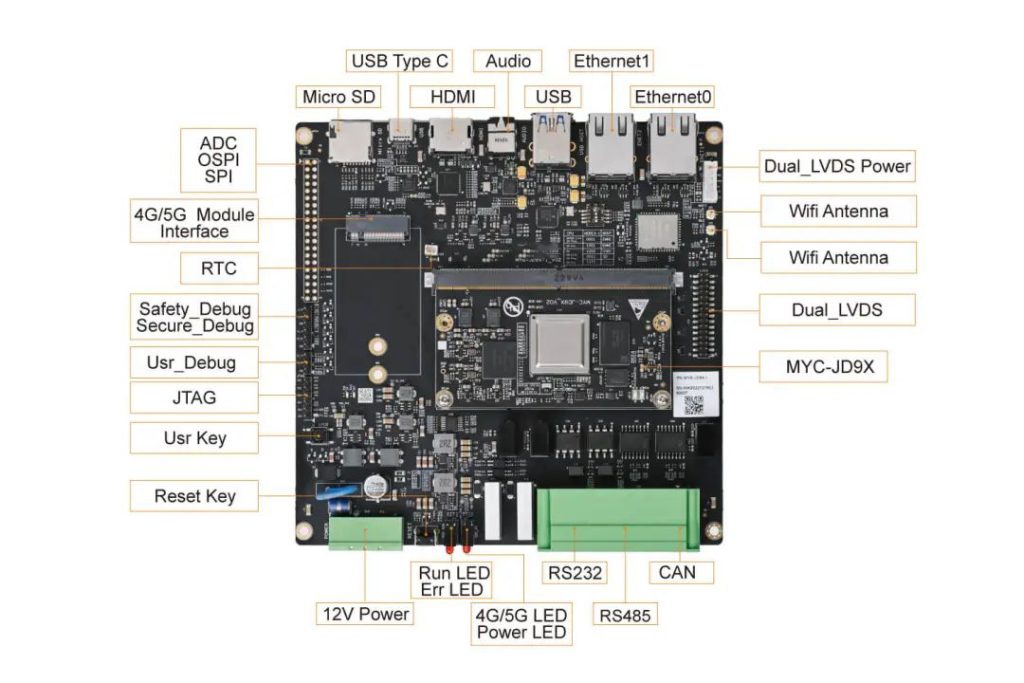

Industrial control boards are key parts of modern automation systems. They help manage and monitor industrial tasks with accuracy. You can find them in factories, power plants, and medicine labs. These boards work like the brain of machines, controlling tools and sensors. By using them, industries can work faster, make fewer mistakes, and get more done.

📌 Tip: Industrial control boards are crucial for industries using smart tech like robots and AI.

Importance of Custom Design and Fabrication

Custom designs make control boards fit specific job needs. These tailored boards work better and match current systems. For example, factories use them to save money and boost production. Energy companies need them to manage power and connect to smart grids. Car makers use them for electric cars and self-driving systems. Medicine companies rely on them for accuracy and following rules.

| Sector | Application | Key Drivers |

|---|---|---|

| Manufacturing | Automation for better quality and lower costs | Growth of smart factories, robots, and AI |

| Energy and Utilities | Managing energy flow and smart grid links | Need for better energy use and smart grid connections |

| Automotive | Making electric and self-driving cars | Demand for advanced systems and high-quality parts |

| Pharmaceuticals | Accurate and reliable production | Following rules and meeting growing healthcare demands |

| Food and Beverages | Automating food production and packaging | Need for safe food and faster production |

Applications of Industrial Control Boards

Industrial control boards are used in many industries. Factories use them for automation to improve quality. Energy companies depend on them for managing power and smart grids. Car makers use them for electric and self-driving vehicles. Medicine companies need them for safety and quality checks. Food companies use them for packaging and production automation.

Human Machine Interfaces (HMIs) and Remote Terminal Units (RTUs) add more uses. HMIs let workers monitor systems easily in real time. RTUs allow remote control of industrial tasks. These features make control boards a must-have for modern industries.

Key Factors for Picking a Provider

Picking the right provider for industrial control board services is important. It can greatly affect how your business runs. To choose wisely, think about these key points:

Experience and Knowledge

A provider’s experience shows how well they can do the job. Choose companies with a history of making quality industrial control boards. Experienced providers know the problems in industries like factories, energy, or healthcare. They can spot issues early and create smart solutions just for you.

Pro Tip: Ask if the provider has worked on projects like yours. This helps ensure they have the right skills for your needs.

Certifications and Rules

Certifications prove a provider cares about safety and quality. Check if they follow rules like ISO 9001 for quality or UL for safety. These show their boards are safe and work well in tough conditions.

Also, following eco-friendly rules is now very important. Providers who care about the environment can help you meet green goals while staying efficient.

Work Examples and Success Stories

A good portfolio shows what a provider can do. Look at their past projects to see how they solve problems. Find examples that match your industry or project. This helps you know if they can handle your needs and make custom solutions.

Note: A clear portfolio builds trust and shows the provider’s skills.

Client Reviews and Testimonials

When choosing a provider for industrial control board services, reviews help a lot. These reviews show how reliable and skilled the provider is. They also tell if the company keeps its promises. By reading what others say, you can see if the provider fits your needs.

Check reviews on trusted sites like Google or LinkedIn. Look for common themes in the feedback. If many reviews praise quality, speed, and service, the provider is likely good. But if there are repeated complaints about delays or poor work, be cautious.

Testimonials on the provider’s website can also give clues. Still, read them carefully since companies often highlight only the best ones. To get a full picture, ask for direct references. Talking to past clients lets you ask specific questions. For example, you can ask how the provider solved problems or made custom solutions.

Tip: Look for reviews about projects like yours. These can show if the provider can handle your specific needs.

Also, notice how the provider reacts to bad reviews. A good company will fix issues and try to improve. This shows they care about their customers and want long-term success.

Client reviews and testimonials are more than opinions. They show how the provider works and treats customers. Use them to make a smart choice and ensure your project is in good hands.

Steps to Find Reliable Industrial Control Board Providers

Searching Online for Providers

Start by looking online for trusted providers. Use search engines to find companies offering industrial control board services. Check their websites to learn about their skills and past work. Look for details about their experience in your field. Also, check if they have safety certifications and follow rules.

You can also use online directories or LinkedIn to find providers. These sites often have reviews and ratings from other clients. Read these to see if the provider is reliable and offers good service. Save the names of companies that match your needs for later review.

Tip: Use keywords like “custom industrial control board services” to get better search results.

Asking Experts for Recommendations

Getting advice from experts can save you time. Talk to coworkers, partners, or mentors who know about industrial control board providers. Ask them about their experiences, including service quality and project results.

Industry events and trade shows are great for meeting providers. These events often have trusted companies showing their services. Use these chances to get recommendations and meet vendors directly.

Pro Tip: When asking for advice, focus on providers with similar project experience.

Meeting Providers for Evaluation

After making a list of providers, set up meetings to learn more. Use these talks to explain your project needs and check their skills. Ask how they handle custom designs and ensure safety and quality.

During the meeting, see if the provider understands your needs. A good provider will ask smart questions and suggest solutions. Notice how they communicate and respond. These things can affect your project’s success.

Note: Write down questions before the meeting to use your time well.

Comparing Quotes and Service Offerings

When looking at quotes, don’t just focus on price. A cheaper option might skip important features or lower quality. Checking the value of each quote helps you decide wisely.

First, check what services each provider includes. Some may offer extras like repairs, help with problems, or longer warranties. Others might charge more for these. Make a list of what your project needs and compare it to their offers. This way, you can spot missing items or extra perks.

Tip: Ask for a clear cost breakdown. This shows what you’re paying for and avoids surprise fees.

Next, think about how long the project will take. A faster timeline might sound great, but make sure quality won’t suffer. Rushed work or delays can cause big problems, especially with complex systems like an industrial control board.

Also, see if the provider can adjust their services for you. Can they customize their work to fit your needs? Custom solutions are helpful, especially for industries needing special designs. Providers with flexible options can grow with your business.

Lastly, check their customer support. Good providers help even after the job is done. They make sure your systems work well over time. Choose companies known for great post-sale service.

By reviewing quotes and services carefully, you can pick a provider that offers the best mix of price, quality, and long-term benefits.

Questions to Ask Industrial Control Board Providers

What Experience Do You Have with Similar Work?

When choosing a provider, ask about their past work. Providers with similar project experience understand your needs better. For example, if you work in factories, pick a provider who has made automation systems for factories before. Their knowledge of industry problems helps finish projects smoothly.

Also, ask about the size of their past jobs. Providers used to big projects may have more tools and ideas. If your project is small, check if they can adjust their methods to fit your needs.

Pro Tip: Request examples of past work in your field. This shows if they can handle your specific project.

Do You Have Certifications for Industry Standards?

Certifications show a provider cares about safety and quality. Ask if they follow rules like ISO 9001 for quality or UL for safety. These prove their control boards meet strict standards.

Also, ask if they follow eco-friendly rules. Providers who care about the environment can help you save energy and stay green.

Note: Certifications lower risks of bad systems or breaking rules.

Can You Share References or Case Studies?

References and case studies help you learn about a provider’s skills. Ask for contacts of past clients to hear about their experiences. Talking to these clients lets you ask about the provider’s work, problem-solving, and meeting deadlines.

Case studies show how the provider solved problems in past projects. Look for examples of custom solutions, especially for tricky systems like industrial control boards.

Tip: Check how they handled surprises in case studies. This shows their ability to solve problems and adapt.

What Is Your Process for Custom Design and Fabrication?

Knowing how a provider handles custom design is important. A clear process ensures the control board fits your needs. It also helps it work well with your current systems.

Good providers usually follow these steps:

- Requirement Analysis: They start by learning about your project. This includes checking your needs, system setup, and challenges.

- Concept Development: Next, they create design ideas. These may include sketches or models to show their plan.

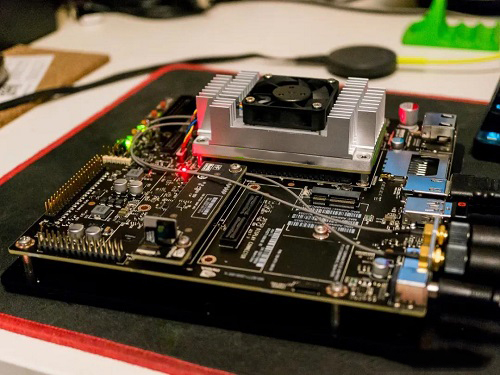

- Design and Engineering: After you agree on the idea, they make detailed designs. This step includes picking parts, making diagrams, and meeting rules.

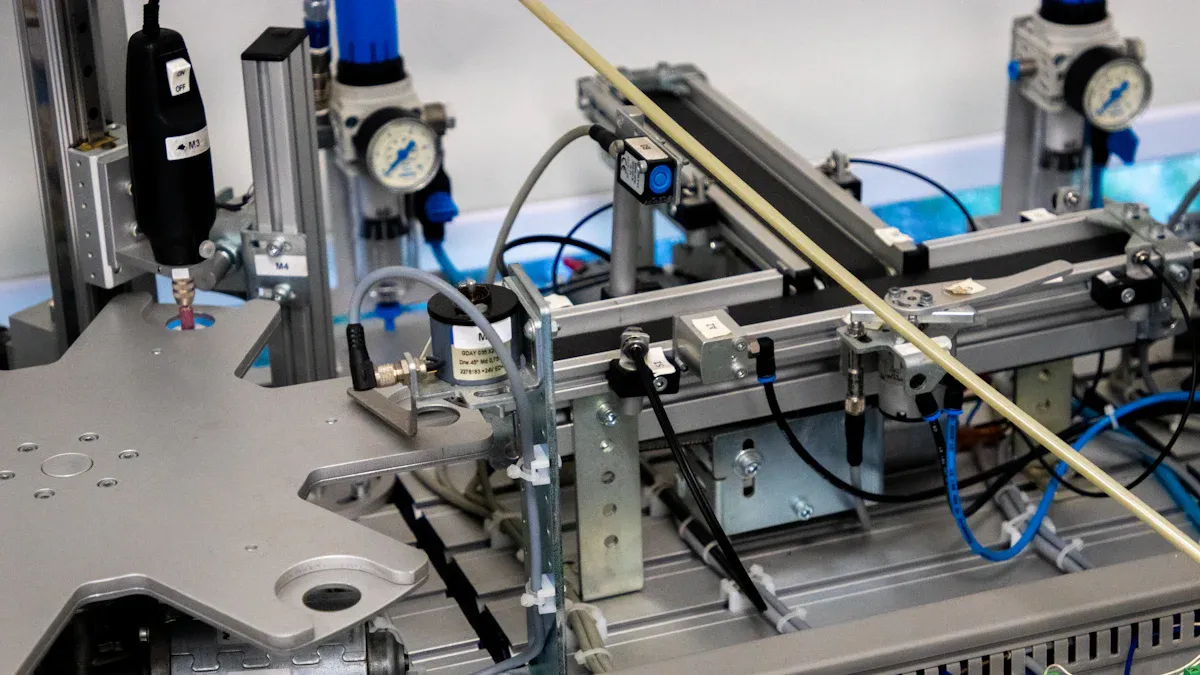

- Fabrication: The control board is built using strong materials and modern tools. They focus on making it last and work accurately.

- Testing and Validation: Before giving it to you, they test the board. They check if it works well, is safe, and performs under different conditions.

Tip: Ask for updates and reports at each step. This keeps you informed and ensures everything is on track.

How Do You Ensure Quality and Safety?

Quality and safety are very important for control boards. A good provider uses strict methods to make sure of both.

- Quality Checks: They test the board at every step to ensure it works well.

- Following Standards: Providers follow rules like ISO 9001 and UL to meet safety and quality levels.

- Strong Materials: They use tough materials that can handle rough conditions.

- Safety Features: Boards are designed with safety tools like overload protection.

- Improving Designs: Providers learn from past projects to make better boards in the future.

📌 Note: Always check if the provider follows safety and quality rules. This reduces risks and ensures the board lasts long.

Benefits of Reliable Industrial Control Board Services

Better Efficiency and Productivity

Good industrial control board services make systems work better. These boards handle repeated tasks automatically, so less manual work is needed. This helps factories produce items faster and in larger amounts. For example, in factories, these boards keep machines working together smoothly. This reduces delays and boosts efficiency.

They also collect data and show real-time updates. This helps find problems and improve how things run. With this technology, you can focus on big goals instead of fixing small issues.

📌 Tip: Using a modern control board keeps you ahead in busy industries.

Safer Workplaces and Following Rules

Safety is very important in industries. Reliable boards have safety tools like emergency stops and overload protection. These features keep workers and machines safe. For example, in power plants, they check voltage to avoid dangers.

Following rules is another big advantage. Providers with certifications like ISO 9001 make sure boards meet safety and quality standards. This lowers risks and avoids fines for breaking rules.

Pro Tip: Check if your provider follows the latest safety and green rules.

Saving Money Over Time

Reliable boards may cost more at first but save money later. They last longer, so you won’t need to fix or replace them often. Their energy-saving features also lower your bills.

These boards also prevent costly mistakes and downtime. For example, they spot problems early and fix them before they get worse. Picking a trusted provider ensures your systems stay efficient and save money over time.

📈 Insight: The money saved over time is worth the upfront cost.

Custom Solutions for Unique Needs

Each industry faces different challenges, so one solution won’t fit all. Custom solutions make sure your industrial control board matches your needs. This helps improve performance, cut downtime, and work better with your systems.

For instance, factories may need boards for fast automation. Energy companies might need boards to manage tricky grid systems. Custom designs meet these needs, making systems work smoothly and reliably.

Pro Tip: Give your provider clear project details. This helps them create a solution that fits perfectly.

Custom solutions also allow for growth. As your business expands, a custom board can adjust to new tools or processes. Providers can use modular parts, making upgrades easy without long delays.

Another benefit is meeting rules. Industries like healthcare and food must follow strict laws. A custom board ensures your work stays within these rules, avoiding fines or problems.

Custom designs don’t just fix today’s issues—they prepare you for tomorrow. By choosing a solution made for you, you gain an advantage and long-term benefits.

📌 Note: Pick a provider with experience in your field. Their knowledge ensures the solution works now and later.

Choosing a good industrial control board provider is very important. Experienced providers offer custom solutions to make work easier and safer. They also help save money over time. Begin by looking up providers near you and checking their skills. This helps you find someone who knows your needs and does great work. Picking the right provider helps your business grow and run smoothly.

FAQ

Which industries benefit the most from industrial control boards?

Industries like factories, energy, cars, medicine, and food production benefit a lot. These boards make work faster, safer, and follow rules. They also improve processes, reduce mistakes, and boost output.

Tip: Pick a provider who knows your industry for better results.

How can I tell if a provider offers custom solutions?

Ask about their design steps and past work. Good providers study your needs, make custom designs, and match them to your systems. They should share examples of similar custom projects they’ve done.

📌 Note: Custom solutions help your system meet special needs.

Are certifications important when choosing a provider?

Yes, certifications like ISO 9001 and UL show the provider meets safety and quality rules. These prove they deliver safe and reliable control boards.

Pro Tip: Always check certifications to avoid problems and ensure good quality.

How long do industrial control boards usually last?

The lifespan depends on materials, design, and care. Good boards can last 10-15 years or more with proper upkeep. Regular checks and updates help them last longer.

Insight: Spending more on quality now saves money later.

Can industrial control boards keep up with new technology?

Yes, modern boards often have modular parts for easy upgrades. This lets them stay useful and competitive as technology changes.

Reminder: Talk about future upgrades with your provider during planning.