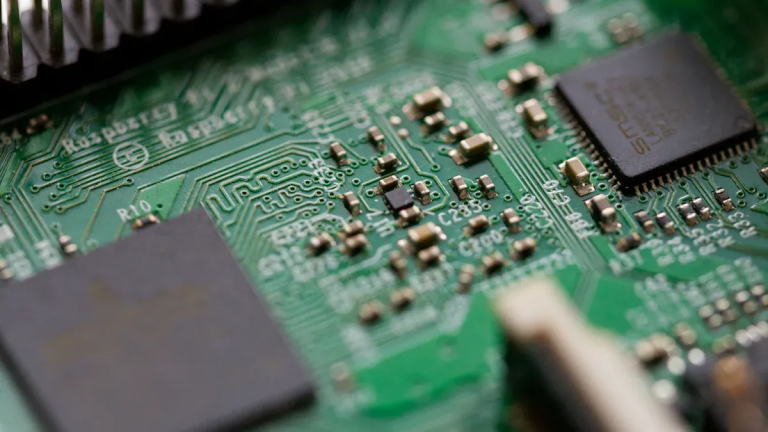

When it comes to modern electronics, multilayer PCBs are a game-changer. They allow you to create devices that are smaller, faster, and more efficient. By stacking multiple layers of circuits in a compact design, these printed circuit boards offer unmatched functionality. Whether you’re designing consumer gadgets or industrial equipment, multilayer PCBs give you the edge to innovate. Their advanced design maximizes performance while ensuring durability. With these printed circuit boards, you can achieve reliable, cutting-edge solutions for any application.

Key Takeaways

- Multilayer PCBs make devices smaller and lighter by stacking circuits. This makes them perfect for small gadgets like smartphones.

- These boards improve performance with faster signals and better signal quality. This is important for modern tech like 5G.

- Multilayer PCBs are strong and handle tough conditions well. They lower the chance of parts breaking, lasting a long time.

- Using multilayer PCBs saves money over time. They need less fixing and last longer.

- They can handle complex designs, so they work in many fields. These include electronics, airplanes, and more.

Compact Design

Smaller and Lighter Devices

Multilayer PCBs allow you to create devices that are both smaller and lighter. By stacking multiple layers of circuits, these circuit boards reduce the overall footprint of your design. This makes them perfect for space-constrained devices like smartphones and wearables.

- Multilayer PCBs achieve significantly smaller footprints compared to single-layer designs.

- The average smartphone today features a PCB with 4-6 layers, while high-end models can have up to 12 layers.

This trend highlights how multilayer designs enable compact and powerful devices. If you aim to build sleek, lightweight products, multilayer PCBs are the way forward.

Space-Saving for Complex Circuits

When dealing with complex circuits, space-saving becomes a priority. Multilayer PCBs excel in this area by minimizing the need for interconnection wiring. This not only reduces the size of your device but also contributes to weight reduction.

- Multilayer PCBs significantly reduce the size of compact devices like smartphones.

- They eliminate bulky wiring, ensuring a streamlined design.

- These features drive the growing demand for multilayer PCBs in the market.

By choosing multilayer circuit boards, you can simplify your design while maintaining functionality.

Ideal for Portable Electronics

Portable electronics demand high functionality in small sizes. Multilayer PCBs meet this challenge by offering higher component density and better electrical performance. They also manage electromagnetic interference effectively, ensuring reliable operation.

| Benefit/Application | Description |

|---|---|

| Higher Component Density | Multilayer PCBs support more routing layers and smaller components, essential for compact devices. |

| Better Electrical Performance | Enhanced signal integrity and reduced noise interference improve overall device functionality. |

| Effective Noise Management | Multilayer designs help in managing electromagnetic interference, crucial for sensitive electronics. |

| Greater Layout Flexibility | Techniques like Any Layer HDI allow for complex routing and component placement across layers. |

These features make multilayer PCBs indispensable for devices like smartphones, tablets, and other portable gadgets. If you want to stay ahead in the competitive electronics market, adopting multilayer PCBs is essential.

Enhanced Performance

High-Speed Signal Transmission

Multilayer PCBs are essential for achieving high-speed signal transmission in modern devices. Their layered structure minimizes signal loss and distortion, ensuring reliable communication even at high frequencies. You can rely on these circuit boards to handle demanding applications like 5G networks and advanced computing systems.

- A simulation of a 50-ohm microstrip trace over a 5-mil dielectric revealed how multilayer designs reduce signal distortion.

- Results showed that without proper multilayer construction, signal transmission dropped by over 5 dB, with a 10 dB return loss at 14 GHz.

By using multilayer PCBs, you can optimize your device’s performance for high-speed data transfer. This makes them indispensable for industries like telecommunications and data centers.

Improved Signal Integrity

Maintaining signal integrity is critical for high-performance devices. Multilayer PCBs excel in this area by offering controlled impedance routing and dedicated ground planes. These features reduce electromagnetic interference (EMI) and ensure stable signal transmission.

| Performance Metric | Description |

|---|---|

| Enhanced Signal Integrity | Facilitates controlled impedance routing, minimizing signal distortion for reliable high-frequency transmission. |

| Reduced EMI | Utilizes dedicated ground and power planes to suppress electromagnetic interference, enhancing reliability. |

| Improved Thermal Management | Offers efficient heat dissipation, enhancing reliability and lifespan of high-power components. |

With these benefits, multilayer circuit boards ensure your devices deliver consistent and reliable performance, even in challenging environments.

Support for Advanced Technologies

Multilayer PCBs are the backbone of advanced technologies. Their ability to accommodate higher component density allows you to integrate more features into compact devices. This makes them ideal for cutting-edge applications across various industries.

- In consumer electronics, multilayer PCBs power smartphones, tablets, and smart home devices.

- Automotive systems like ADAS and infotainment rely on these circuit boards for their enhanced design functionality.

- Aerospace, medical, and industrial automation sectors also depend on multilayer PCBs for high-quality performance.

By adopting multilayer PCBs, you can future-proof your designs and stay ahead in a competitive market. Their versatility and performance make them a smart choice for any advanced application.

Durability and Reliability

Robust Construction for Long-Term Use

When you choose multilayer PCBs, you invest in a robust solution designed for long-term use. These circuit boards are built with high-quality materials and advanced manufacturing techniques, ensuring they can withstand the demands of modern devices. Their mechanical strength surpasses that of single-layer or double-layer PCBs, making them ideal for applications where durability is non-negotiable.

Multilayer PCBs are trusted in critical fields like medical imaging, aerospace, and industrial automation. Their ability to perform reliably under extreme conditions makes them indispensable in these industries.

| Metric | Multilayer PCBs | Double-Layer PCBs | Single-Layer PCBs |

|---|---|---|---|

| Signal Integrity | High | Moderate | Low |

| Thermal Management | Excellent | Good | Poor |

| Mechanical Strength | High | Moderate | Low |

By opting for multilayer circuit boards, you ensure your devices maintain peak performance over time, even in challenging environments.

Resistance to Environmental Stress

Multilayer PCBs excel in resisting environmental stress, making them a reliable choice for devices exposed to harsh conditions. These circuit boards undergo rigorous testing to ensure they can handle extreme temperatures, humidity, and corrosive atmospheres.

- High Accelerated Temperature and Humidity Stress Testing (HAST) evaluates their ability to endure prolonged exposure to heat and moisture.

- Temperature Cycling Testing subjects them to alternating high and low temperatures, ranging from -55°C to 125°C.

- Salt Spray Testing assesses their resistance to corrosive environments, such as those containing salt or chloride compounds.

Thermal cycling tests also demonstrate how multilayer designs handle expansion and contraction without compromising performance. This resilience ensures your devices remain operational, even in the most demanding conditions.

Reduced Risk of Component Failure

Multilayer PCBs significantly reduce the risk of component failure, thanks to their advanced design and construction. By incorporating dedicated ground planes and controlled impedance routing, these circuit boards minimize electrical noise and signal distortion. This not only enhances performance but also prevents issues that could lead to component damage.

Their superior thermal management capabilities further contribute to durability. Efficient heat dissipation protects sensitive components from overheating, extending the lifespan of your devices. Whether you’re designing consumer electronics or industrial equipment, multilayer PCBs provide the reliability you need to build trust with your customers.

With multilayer PCBs, you can confidently deliver products that perform consistently and last longer, even under challenging conditions.

Versatility in Multilayer PCB Applications

Consumer Electronics (e.g., smartphones, laptops)

Multilayer PCBs are at the heart of modern consumer electronics. They enable the compact, high-performance devices you use daily, such as smartphones, laptops, and tablets. These circuit boards support the structural and electrical functionality of these gadgets, ensuring seamless operation.

- The consumer electronics segment accounted for over 25% of the global multilayer PCB market revenue in 2023.

- The market is projected to grow from $71 billion in 2023 to $116.1 billion by 2032, driven by the rising demand for personal electronic devices.

Multilayer PCBs allow manufacturers to integrate advanced features into smaller designs. This makes them indispensable for wearables, smart home devices, and IoT gadgets. By adopting these circuit boards, you can create innovative products that meet the growing expectations of tech-savvy consumers.

Automotive and Aerospace Industries

In the automotive and aerospace sectors, multilayer PCBs play a critical role in powering advanced systems. These industries demand circuit boards that deliver high reliability and performance under extreme conditions.

| Segment | Description |

|---|---|

| Multilayer | Fastest-growing segment in automotive PCBs, driven by HUDs, camera modules, and telematics. |

| Demand Drivers | Increased need for complex circuits and miniaturization in mission-critical applications. |

Multilayer PCBs are essential for engine control units, ADAS components, and vehicle infotainment systems. In aerospace, they support mission-critical hardware and unmanned vehicles. Their ability to handle complex circuits and harsh environments makes them the preferred choice for these demanding applications.

Medical Devices and Industrial Equipment

The medical and industrial sectors rely on multilayer PCBs for their precision and durability. These circuit boards meet stringent regulatory standards, ensuring safety and effectiveness in critical applications.

| Compliance Standard | Description |

|---|---|

| ISO 13485 | Quality management systems for medical devices. |

| IPC-6012 Class 3 | Standards for rigid printed boards. |

| IEC 60601 | Safety and effectiveness of medical equipment. |

Multilayer PCBs are used in medical imaging devices, robotic surgical systems, and industrial automation equipment. They undergo rigorous quality control tests, such as thermal shock and environmental stress screening, to ensure reliability. By incorporating these circuit boards into your designs, you can deliver high-quality products that meet industry standards.

Multilayer PCB applications span diverse industries, from consumer electronics to aerospace and healthcare. Their versatility and performance make them a cornerstone of modern technology.

Cost Efficiency in the Long Run

Reduced Maintenance Costs

Multilayer PCBs help you save significantly on maintenance expenses. Their advanced design minimizes the risk of component failure, reducing the need for frequent repairs. Unlike traditional PCBs, multilayer options offer better thermal management and enhanced durability. This means your devices can operate efficiently for longer periods without requiring costly interventions.

For example, by using high-quality materials like Rogers RT Duroid 5880, you can cut annual downtime costs from $40,000 to just $8,000. This reduction in maintenance translates to substantial savings over time, making multilayer PCBs a cost-effective choice for your projects.

Investing in multilayer PCBs ensures your devices remain reliable, reducing the financial burden of ongoing maintenance.

Longevity Offsets Initial Investment

While multilayer PCBs may have a higher upfront cost, their longevity makes them a smart investment. These circuit boards are built to last, offering superior performance over extended periods. This durability offsets the initial expense, providing a better return on investment (ROI) compared to traditional PCBs.

| Parameter | Traditional PCB | Rogers RT Duroid 5880 |

|---|---|---|

| Initial Material Cost | Lower | Higher |

| Downtime Cost (Annually) | $40,000 | $8,000 |

| Maintenance Costs | Higher | Lower |

| Total ROI (5 Years) | $160,000 | $120,000 |

By choosing multilayer PCBs, you can reduce downtime and maintenance costs, ensuring your devices deliver consistent performance. Over time, the savings far outweigh the initial investment, making these circuit boards a financially sound choice.

Scalability for Mass Production

Multilayer PCBs excel in scalability, making them ideal for mass production. Their ability to support complex designs allows you to create a wide range of devices, from simple consumer electronics to advanced computing systems. As the layer count increases, so does the complexity and functionality of your products.

| Layer Count | Complexity | Cost Impact | Typical Applications |

|---|---|---|---|

| Single Layer | Lowest | Lowest | Simple Electronics, Low-Density Applications |

| Double Layer | Low | Low to Medium | Basic Consumer Electronics, Simple Microcontrollers |

| 4 Layer | Medium | Medium | More Complex Consumer Electronics, Industrial Controllers |

| 6 Layer | Medium to High | Medium to High | Advanced Consumer Electronics, Telecommunication Devices |

| 8+ Layer | High | High | High-Performance Computing, High-Speed Data Systems |

This scalability ensures you can meet the demands of various industries while keeping production costs manageable. Whether you’re manufacturing smartphones or high-speed data systems, multilayer PCBs provide the flexibility and efficiency you need to scale your operations effectively.

By leveraging the scalability of multilayer PCBs, you can streamline production and deliver high-quality products to market faster.

Multilayer PCBs transform the way you design and build modern devices. They offer compact layouts, superior performance, and unmatched durability. Their versatility makes them essential across industries, from consumer electronics to aerospace. By adopting multilayer technology, you can create cutting-edge devices that are reliable and efficient.

Don’t let outdated designs hold you back. Embrace multilayer PCBs to stay ahead in innovation and deliver exceptional products to your customers.

FAQ

What is a multilayer PCB, and why is it important?

A multilayer PCB consists of multiple layers of circuits stacked together. It allows you to create compact, high-performance devices. These circuit boards are essential for modern electronics, enabling advanced designs and reliable functionality in industries like consumer electronics, automotive, and aerospace.

How does a multilayer PCB improve device performance?

Multilayer PCBs enhance performance by supporting high-speed signal transmission, reducing electromagnetic interference, and improving thermal management. These features ensure your devices operate efficiently and reliably, even in demanding applications like 5G networks or advanced computing systems.

Are multilayer PCBs more durable than single-layer PCBs?

Yes, multilayer PCBs are more durable. Their robust construction and advanced materials make them resistant to environmental stress, such as extreme temperatures and humidity. This durability ensures your devices last longer and perform consistently.

Can multilayer PCBs reduce production costs?

While multilayer PCBs have a higher initial cost, they reduce long-term expenses. Their durability minimizes maintenance costs, and their scalability supports mass production. Over time, these benefits offset the upfront investment, making them a cost-effective choice.

What industries benefit most from multilayer PCBs?

Multilayer PCBs are vital in industries like consumer electronics, automotive, aerospace, and medical devices. They enable compact designs, advanced functionality, and reliable performance, making them indispensable for smartphones, ADAS systems, medical imaging equipment, and more.