High-mix low-volume PCBA involves producing small batches of printed circuit board assemblies with varying designs and configurations. This approach is crucial for modern manufacturing. You face challenges like fluctuating customer demands, supply chain uncertainties, and the need for mass customization. Adopting this method allows you to stay agile, meet unique requirements, and adapt swiftly to industry regulations.

Key Takeaways

- High-mix low-volume PCBA helps factories adjust fast to customer needs. It keeps production flexible and quick to respond.

- This way of making products saves money on small orders. It reduces waste, uses resources wisely, and keeps quality high.

- HMLV production speeds up how fast new products are made. It helps launch products quicker with better tools and simple steps.

Understanding High-Mix Low-Volume PCBA

What is High-Mix Low-Volume PCBA?

High-mix low-volume PCBA refers to the production of printed circuit board assemblies (PCBs) in small quantities while accommodating a wide variety of designs and configurations. This approach is tailored to meet the demands of industries that require flexibility and customization. Unlike traditional manufacturing, which focuses on mass production, high-mix low-volume PCBA prioritizes adaptability to handle diverse product requirements.

You often encounter this method in industries like aerospace, medical devices, and consumer electronics, where rapid prototyping and small-batch production are critical. For example, a 2023 industry survey revealed that 68% of businesses now expect functional prototypes within 72 hours, compared to a 10-day average in 2020. This shift highlights the growing need for agile and responsive manufacturing processes.

Key Characteristics of HMLV Production

HMLV production stands out due to its unique features that cater to modern manufacturing needs. These characteristics ensure that you can deliver high-quality products while maintaining efficiency and cost-effectiveness. Key metrics that define HMLV production include:

| Metric | Description |

|---|---|

| Defects per Million Opportunities (DPMO) | Measures the number of defects found per million opportunities for defects, allowing for standardized quality comparisons. |

| First Pass Yield (FPY) | Represents the percentage of PCBs passing all quality inspections on the first attempt, indicating process efficiency. |

| Rework Rate | Measures the percentage of PCBs requiring additional work after initial assembly, with a low rate indicating high quality. |

| Scrap Rate | Represents the percentage of unusable PCBs due to defects, with a lower rate indicating better productivity. |

HMLV production also requires frequent changeovers, advanced testing methods, and a highly skilled workforce. These elements ensure that you can meet the demands of diverse and complex projects without compromising quality or efficiency.

How HMLV Differs from Traditional Low-Volume PCB Assembly

HMLV manufacturing differs significantly from traditional low-volume PCB assembly in terms of processes, challenges, and outcomes. While traditional methods focus on stable production with minimal variations, HMLV production emphasizes flexibility and adaptability. Here’s a comparison to help you understand the key differences:

| Aspect | High-Mix Low-Volume PCBA | Traditional Low-Volume PCB Assembly |

|---|---|---|

| Manufacturing Process | Requires high flexibility and frequent changeovers | More stable with less frequent changes |

| Supply Chain Challenges | Higher complexity with diverse BOM and hidden costs | Simpler supply chain with fewer components |

| Cost Implications | Higher hidden costs due to low purchase volumes | More predictable costs with bulk purchasing |

| Testing Requirements | Additional tests like High Voltage, RF Testing | Standard tests like AOI and ICT |

| Efficiency | Lower overall efficiency due to variability | Higher efficiency with consistent production flow |

For instance, a medical device manufacturer adopting HMLV production achieved a 30% reduction in time-to-market and a 15% improvement in product quality by implementing modular production lines and advanced inspection systems. This demonstrates how HMLV production can address the limitations of traditional methods, especially in dynamic and innovation-driven industries.

Benefits of High-Mix Low-Volume PCBA

Flexibility in Production Processes

HMLV production offers unmatched flexibility, enabling you to adapt quickly to changing demands and diverse project requirements. By relying on standard operating procedures and advanced scheduling tools, you can manage frequent changeovers without compromising efficiency. For instance, enterprise resource planning (ERP) software helps streamline inventory management and scheduling, reducing downtime and ensuring consistent output.

Onshore PCB contract manufacturers are particularly well-suited for HMLV production. Their operational setups are optimized for small batch sizes and high product variety, making them ideal partners for projects requiring precision and customization. Additionally, flexible manufacturing systems allow you to switch seamlessly between different products and volumes, ensuring you meet tight deadlines and customer expectations.

| Metric | Description |

|---|---|

| Lead Time | Shortened through proactive scheduling and alignment with customer demand. |

| Cycle Time | Improved by modular production approaches, enabling quick changeovers. |

| Machine Utilization | Increased through machine learning integration for operational efficiency. |

These metrics highlight how HMLV production enhances flexibility, allowing you to deliver high-quality PCBs while maintaining agility in your processes.

Cost-Effectiveness for Small-Batch Manufacturing

HMLV manufacturing is a cost-effective solution for producing customized electronic products in small batch sizes. Unlike traditional methods that rely on bulk production, HMLV production minimizes waste and optimizes resources for low-volume projects. This approach is particularly beneficial for industries like consumer electronics, medical devices, and automotive systems, where precision and customization are critical.

- The growing demand for high-mix, low-volume production in the electronics market underscores its cost-effectiveness.

- Manufacturers specializing in this segment provide efficiency and customization to meet unique project requirements.

- Flexible production lines reduce setup times, further lowering costs for small-batch manufacturing.

By adopting HMLV production, you can achieve significant cost savings while maintaining the quality and precision required for complex PCB designs.

Faster Time-to-Market for New Products

In today’s competitive landscape, faster time-to-market is essential for staying ahead. HMLV production enables you to accelerate product launches by leveraging digital tools and streamlined processes. For example, achieving a first-time-right outcome in the PCBA new product introduction (NPI) process reduces both time and costs, ensuring your products reach the market quickly.

- Digital tools interpret build intent and mitigate risks, enhancing efficiency.

- Modular production lines and advanced inspection systems support rapid prototyping and quick turnarounds.

- Specialization in low quantities and complex designs allows you to meet tight project schedules.

These strategies not only reduce time-to-market but also enhance your ability to innovate and respond to market demands effectively.

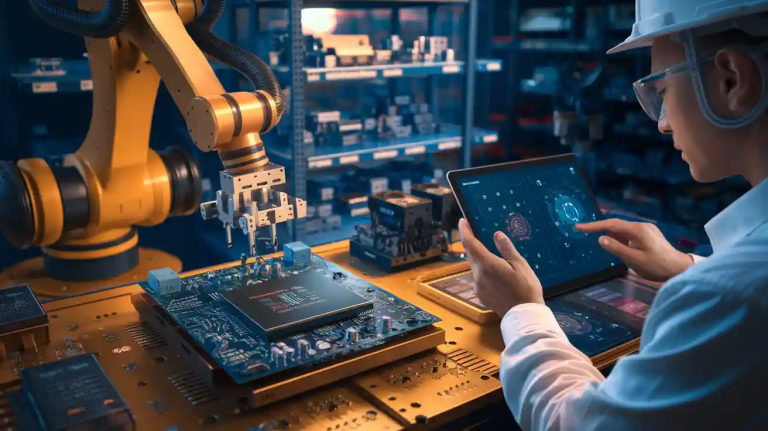

Customization and Innovation Opportunities

HMLV production opens the door to unparalleled customization and innovation. By leveraging advanced technologies like AI and flexible automation, you can adapt easily to new customer requests and product types. For instance, Robovision’s AI platform enables automated optical inspection (AOI) machine builders to industrialize customization, reducing setup time and enhancing flexibility.

Robovision’s AI platform allows AOI machine builders to industrialize customization, reducing set-up time and adapting easily to new customer requests and product types. This demonstrates the efficiency and flexibility needed for low-volume, high-mix PCBA production.

| Aspect | Impact on Customization Trends in Small-Batch PCB Assembly |

|---|---|

| Flexibility | Enhanced flexibility in production lines for custom orders |

| Efficiency | Improved efficiency reduces setup times for small batches |

| Accessibility | Custom orders are now more accessible to a wider range of customers |

By embracing HMLV production, you can deliver tailored solutions that meet the unique needs of your customers while fostering innovation in your manufacturing processes.

The Role of High-Mix Low-Volume PCBA in Modern Manufacturing

Meeting Diverse Customer Demands with HMLV Production

HMLV production empowers you to meet the ever-changing demands of customers by offering unparalleled flexibility. Advanced manufacturing techniques, such as 3D printing, allow you to adapt quickly to unique requirements through digital designs. Additive manufacturing further enhances this capability by enabling on-demand production without extensive retooling. However, challenges like retooling and repetitive assembly steps can hinder efficiency in high-mix environments.

| Key Factors/Challenges | Description |

|---|---|

| Advanced Manufacturing Techniques | Use of 3D printing enables quick adaptation to customer requirements through digital designs. |

| Flexibility of Additive Manufacturing | Allows for on-demand production without extensive retooling, catering to diverse customer needs. |

| Challenges in PCB Production | Issues like retooling, repetitive assembly steps, and moving away from panelization hinder high-mix, low-volume production. |

By leveraging these technologies, you can address diverse customer needs while maintaining improved quality control and operational efficiency.

Supporting Rapid Technological Advancements

HMLV production plays a pivotal role in supporting rapid technological advancements. The demand for miniaturization and advanced manufacturing techniques continues to grow, as highlighted in the “Multi-Board PCB Market’s Technological Evolution” report. The global rapid prototyping PCB assembly market, for instance, is projected to grow from $1.8 billion in 2023 to $3.5 billion by 2028, driven by faster product development cycles and innovation.

- The market is experiencing a CAGR of 15%, reflecting the increasing adoption of HMLV manufacturing.

- Leading companies are integrating advanced technologies to maintain their competitive edge.

- Trends like embedded components and flexible PCBs are driving innovation in various sectors.

These advancements enable you to stay ahead in a competitive landscape while delivering high-quality products.

Enhancing Competitiveness in Dynamic Markets

HMLV manufacturing enhances your competitiveness by aligning with key industry metrics. Factors like annual revenue, production volume, and technological capabilities determine your market position. For example, companies that adopt automation and Industry 4.0 technologies improve efficiency and maintain a strong foothold in the market.

| Ranking Factor | Description | Weighting |

|---|---|---|

| Annual Revenue | Total revenue generated from PCB sales, reflecting the overall market share and financial performance. | 30% |

| Production Volume | Quantity of PCBs manufactured annually, indicating the scale of operations and production capacity. | 25% |

| Technological Capabilities | Assessment of advanced manufacturing technologies, including HDI, flexible PCB, and advanced materials processing. | 25% |

| Geographic Reach | Distribution of manufacturing facilities and customer base across different regions, highlighting global presence. | 10% |

| Customer Base and Industry Focus | Diversity and prestige of clients across sectors like automotive, aerospace, and medical, reflecting specialized capabilities. | 10% |

By focusing on these metrics, you can strengthen your position in dynamic markets and deliver high-quality PCBs that meet industry demands.

High-Mix Low-Volume PCBA offers unmatched flexibility, cost-efficiency, and innovation. It empowers you to adapt to modern manufacturing demands while maintaining a competitive edge. Industries like automotive, aerospace, and medical devices benefit significantly.

| Application Fields | Industries Benefiting |

|---|---|

| Industrial Control | Automotive Electronics, Communication Equipment |

| Medical Instruments | Aerospace, Security Electronics |

| R&D Stage | National Defense, Military Industry |

By embracing HMLV production, you can meet diverse customer needs and drive technological advancements effectively.

FAQ

What industries benefit the most from low-volume pcb assembly?

Industries like aerospace, medical devices, and automotive electronics benefit significantly. These sectors demand precision, customization, and flexibility, which low-volume pcb assembly effectively provides.

How does low-volume pcb assembly ensure quality in small batches?

It uses advanced testing methods like automated optical inspection (AOI) and in-circuit testing (ICT). These processes ensure every pcb meets stringent quality standards.

Why is low-volume pcb assembly cost-effective for small projects?

It minimizes waste and optimizes resources by focusing on small-batch production. This approach reduces overhead costs while maintaining high-quality standards for complex pcb designs.