Choosing the right PCB SMT service provider is crucial for your project’s success. Effective assembly requires a partner who thoroughly understands your needs. They should be aware of your production size, design complexity, and deadlines. Specialized services such as fast prototyping and large-scale production can be extremely beneficial. A comprehensive understanding of your requirements fosters better collaboration and outstanding results.

Key Takeaways

- Picking the right PCB SMT provider gives you good products. Check for certifications like ISO 9001 to ensure quality.

- Talking clearly with your provider prevents delays. Pick a provider with helpful customer service and fast replies.

- Ask for samples before making everything. Testing samples finds problems early and checks if quality is good.

Why Picking the Right PCB SMT Service Provider is Important

Making Sure Products Work Well and Last Long

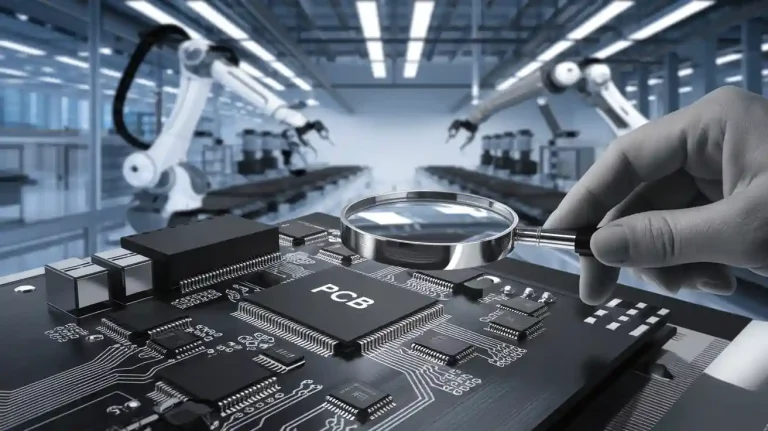

The PCB SMT provider you choose affects your product’s quality. A good provider checks everything carefully to meet industry rules. This ensures your PCBs work as they should. It lowers the chance of problems and makes your product more reliable. For example:

- Providers with ISO 9001 certification show they care about quality.

- Skilled workers and advanced tools catch and fix issues early.

Good PCB services also protect your brand by avoiding bad products. High-quality work means fewer recalls, saving money and keeping your reputation strong.

Avoiding Expensive Errors

Working with an experienced PCB provider helps prevent costly mistakes. Experts know how to handle tricky designs and special needs. They can suggest ways to improve your PCB design for easier production. This reduces errors and makes things more efficient.

Here are some examples of cost-saving solutions:

| Client Type | Problem Faced | Solution Given | Outcome Achieved |

|---|---|---|---|

| Small Electronics Business | Needed high-quality PCBs for a new product but had a tight budget. | Suggested better design, picked cheaper parts, and used flexible setups. | Saved 30% on costs without losing quality. |

| Big Manufacturer | Wanted to cut costs on a large production run. | Recommended design changes and improved the assembly process. | Cut costs by 15% and made products more reliable. |

| Research Lab | Needed complex PCBs for a special project with strict quality demands. | Used advanced methods and strict testing. | Met all quality needs while saving 20% on costs. |

These examples show how good PCB providers save money while keeping quality high.

Staying on Schedule

Finishing on time is very important in PCB assembly. A dependable provider helps you meet deadlines with fast and reliable service. This is crucial for quick prototypes or tight schedules.

Good customer support also helps solve problems quickly. Providers with great communication can fix issues fast, avoiding delays and keeping your project on track.

By picking the right PCB SMT provider, you can balance quality, cost, and speed. This ensures your project finishes on time and meets your expectations.

Key Things to Think About for the Best PCB Service

Picking the right PCB service means checking important details. These steps help you get reliable, high-quality, and affordable PCBs. Below are the main points to consider when choosing a PCB service.

Quality Rules and Certifications

Quality is the most important thing in PCB services. Certifications like ISO 9001 and IPC-A-610 show the provider cares about quality. These certifications mean they follow strict rules to make good PCBs.

| Standard | How It Helps |

|---|---|

| IPC-A-600 | Makes sure PCBs match designs and avoid common problems. |

| ISO 9001 | Proves the provider focuses on quality and works efficiently. |

| Statistical Process Control (SPC) | Tracks production to reduce mistakes and improve results. |

| Lean Manufacturing | Cuts waste and improves workflow, making better products. |

Look for these certifications to ensure the provider delivers reliable and high-quality PCBs.

Advanced Technology Skills

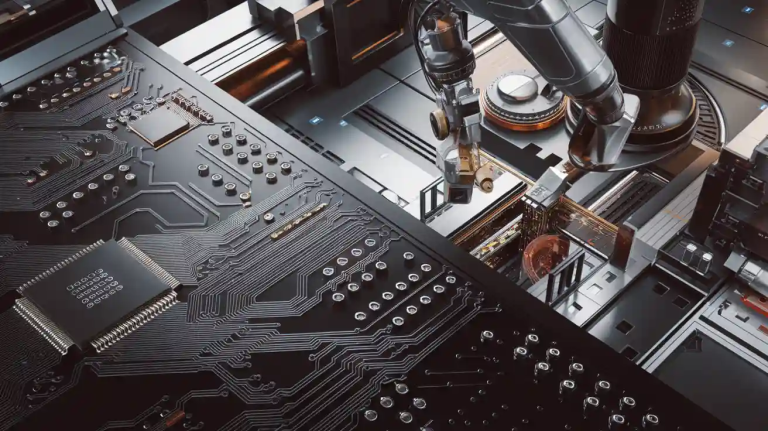

Top PCB providers use new technology to meet different needs. SMT, automation, and 3D printing are examples of tools that improve speed and quality.

| Technology Type | Benefits |

|---|---|

| Better Materials | Stronger materials make PCBs last longer and work better. |

| Automation | Speeds up assembly and makes it more accurate. |

| Surface Mount Technology (SMT) | Allows smaller parts and better placement for improved devices. |

| 3D Printing | Helps create detailed circuits and custom designs. |

| Eco-Friendly Practices | Reduces waste and saves energy during production. |

| AI Tools | Makes production faster and reduces errors. |

A provider with these skills can handle tricky designs and save money without losing quality.

Fast Delivery and On-Time Service

Getting PCBs on time is very important. Providers with quick delivery and good schedules help you stay on track. Look for services with First Article Inspection (FAI) and clear plans to avoid delays.

| Proof | How It Helps |

|---|---|

| First Article Inspection (FAI) | Speeds up checks, reduces mistakes, and ensures faster delivery. |

| Clear Plans | Prevents confusion and speeds up the assembly process. |

| Early Problem Fixing | Solves issues early to avoid delays and late shipments. |

Choose providers with strong delivery systems to keep your project moving smoothly.

Clear Costs and Smart Spending

Knowing the costs helps you manage your budget better. A detailed cost list, including parts, labor, and testing, avoids surprises and helps you spend wisely.

| Cost Part | What It Covers |

|---|---|

| Buying Parts | Costs for getting the electronic components. |

| Making the PCB | Money spent on building the PCB. |

| Assembly Work | Labor costs for putting the parts together. |

| Testing | Expenses for checking the quality of the PCBs. |

- Knowing what costs the most helps you plan better.

- Detailed price lists let you avoid hidden fees.

- Clear pricing ensures you get good value for your money.

Good Support and Communication

Great customer support and clear communication are key to success. Providers who answer quickly and keep you updated make the process easier.

| Task | How It Helps |

|---|---|

| First Contact | Answers questions and solves problems quickly. |

| Order Handling | Makes sure orders are correct and materials are ready. |

| Updates | Keeps you informed about your order’s progress. |

| Watching Production | Ensures everything is on schedule for delivery. |

| Service Improvement | Tracks performance to make services better. |

Quick replies and clear updates build trust and make the process smooth. Good communication also avoids mistakes and keeps you happy.

Growing with Your Needs

As your business grows, your PCB provider should grow with you. The global PCB market, worth $65 billion in 2023, shows the need for flexible services. Providers offering full-service PCB solutions can adjust to your changing needs.

| Fact | Number |

|---|---|

| PCB Market Value (2023) | $65 Billion |

| EMS Market Value (2022) | $455 Billion |

| EMS Market Prediction (2030) | $775 Billion |

| Growth Rate (2023-2030) | 6.2% |

| Smartphones Shipped (2022) | 1.35 Billion Units |

| Electric Cars on Roads (2022) | Over 10 Million |

Flexible providers help you handle bigger orders and follow market trends without losing quality.

Steps to Pick the Right Turnkey PCB Provider

Know What Your Project Needs

First, figure out what your project requires. Decide if you need prototyping, small-batch, or large-scale PCB production. Think about your design’s complexity, materials, and how fast you need it done. Writing down these details helps you explain your needs clearly. This way, you can find the best PCB service for your project.

Look Up and Compare Providers

Search for turnkey PCB providers and compare their skills. Check their certifications, tools, and methods. Use the table below to see how their attachment methods match your needs:

| Attachment Method | Key Stats | Reliability Level | Ease of Use |

|---|---|---|---|

| High Temperature Solder | Peak heat, rising slope, time above reflow | High | Medium |

| Aluminum Tape | Peak heat, rising slope, time above reflow | Medium | High |

| Kapton Tape | Peak heat, rising slope, time above reflow | Medium | High |

| Conductive Epoxy | Peak heat, rising slope, time above reflow | Low | Low |

This table helps you pick a provider that fits your technical and quality needs.

Get Quotes and Compare Offers

Ask different providers for price quotes to compare costs. This helps you find good deals and save money. Keep these tips in mind:

- Comparing quotes shows where you can save money.

- Your design and materials affect the final price.

- Grouping orders with others can lower costs even more.

By checking these things, you can choose a provider that offers both good prices and quality.

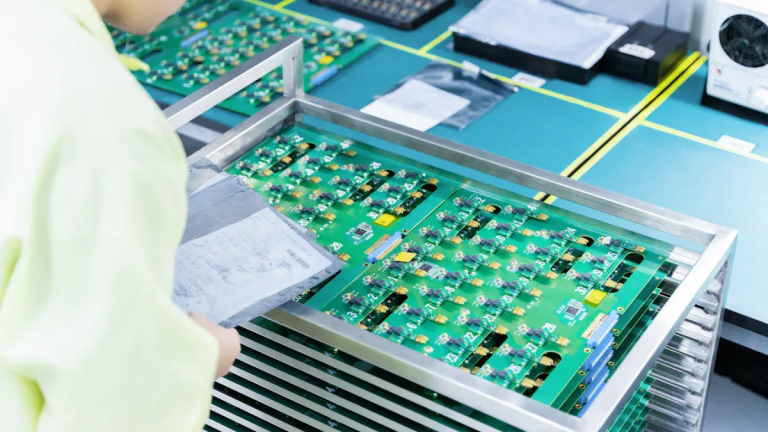

Test Samples to Check Quality

Before starting full production, ask for samples from providers. Testing these samples ensures their PCB services are reliable. Sample testing helps you:

- Spot problems early to avoid bad products later.

- Save time and money by fixing issues before production.

- Make sure the quality meets your standards from the start.

This step ensures the provider can deliver consistent, high-quality results.

Check Reviews and Reputation

Lastly, read reviews and check the provider’s reputation. Look for customer feedback, case studies, and online ratings. Providers with good reviews often deliver on time and meet high standards. Positive feedback shows they are reliable and efficient.

Picking the best PCB SMT service provider helps your project succeed. It ensures great quality, dependability, and smart spending. Pay attention to key things like:

- Quality standards

- Technical capabilities

- Turnaround time

- Customer support

🛠️ Pro Tip: Use the listed steps to check providers. This helps you choose one that fits your needs and project goals.

FAQ

What is the difference between SMT and THT in PCB assembly?

SMT places parts directly on the PCB’s surface. THT uses drilled holes to hold parts, making them stronger.

How do I ensure my PCB design works with SMT assembly?

Follow design rules for manufacturing (DFM). Check pad sizes, spacing, and part placement. Work with your provider to review and improve your design.

Can a PCB SMT provider handle both prototyping and mass production?

Yes, many providers can do both. They start with small prototypes and scale up to large production as needed.

💡 Pro Tip: Check if a provider can grow with your needs. This ensures they can handle both current and future projects.