Choosing the right PCB assembly service is very important. It affects your product’s quality, delivery time, and business goals. A good partner helps you meet industry needs and grow. They also help you stay competitive in a fast-changing market.

Think about these important points when picking a service:

- Good supply chain keeps quality high and delivery on time.

- Helpful customer service makes teamwork and changes easier.

- Flexibility lets you adjust quickly to market changes.

- Scalability helps your business grow and saves money.

- Caring for the environment supports green practices.

By following these tips, you can build a strong partnership.

Key Takeaways

- Know what your project needs. Think about size, goals, and features to make sure the PCB fits your plan.

- Pick a PCB service with good quality checks and approvals. This keeps your products safe and dependable.

- Check if the manufacturer has experience and communicates well. A good partner can make designs better and fix errors.

- Look for clear pricing. This helps you compare options and avoid surprise costs.

- Focus on customer support. Quick replies and good communication help finish projects smoothly and solve problems fast.

Understanding Your Business Needs

Define Your Project Requirements

The first step is knowing what your project needs. Understand the size and goals of your project. Talk to team members to set clear objectives. List the main and extra features your PCB must have. For example, if fast data processing is needed, make it a priority.

Next, decide how to measure performance. Pick key factors like energy use, speed, or strength. Think about challenges like weather that could affect materials. For example, PCBs in factories might need to handle heat or shaking. Also, check market rules and certifications. For instance, RoHS ensures eco-friendly safety.

Set Your Budget and Timeline

A good budget and timeline keep your project on track. Plan money based on your goals and needs. For example, check profits monthly to spot changes early. Use weekly cash flow plans to avoid problems.

Here’s a simple table to help with planning:

| KPI Metric | Benchmark/Value |

|---|---|

| Profit Margin | Usually 10-15% |

| Cash Flow Ratio | 1.2-1.5 for balance |

| ROI on New Equipment | Aim for 20-25% |

| Cost Per Unit Reduction | Target 5-10% yearly |

Follow these tips to stay on budget and meet deadlines. Match your budget and timeline with the PCB company’s abilities to avoid issues.

Consider Industry-Specific Needs

Different industries need different PCB materials and designs. For example, aerospace uses flexible materials like polyimide (PI) for strength. Factories may use rigid ones like FR-4 for stability. Here’s a quick guide:

| Application Areas | Substrate Types | Laminate Materials |

|---|---|---|

| Industrial Electronics | Rigid | FR-4, FR-4 high Tg, FR-4 halogen-free |

| Aerospace & Defense | Flexible | Standard & Others, Flexible (PI, PET) |

| IT & Telecom | Rigid-flex | Paper, Composites |

Knowing these details helps meet industry rules. Work with your PCB company to pick the right materials and designs.

Evaluating the Best PCB Manufacturer

Picking the right PCB manufacturer is very important. A good company helps your project succeed with their skills. They offer quality checks, technical help, and needed services. Here’s how to choose the best partner.

Quality and Standards Compliance

Quality and meeting standards should come first when choosing. Certified manufacturers show they make safe and reliable PCBs. Below are some key certifications:

| Certification | Description | Importance |

|---|---|---|

| AS9100 | Quality rules for aerospace industry. | Ensures PCBs work well in critical aerospace uses. |

| IPC Standards | Industry rules for PCB design and making. | Guides best practices for PCB production. |

| UL Certification | Shows safety and compliance with UL rules. | Ensures PCBs are electrically safe. |

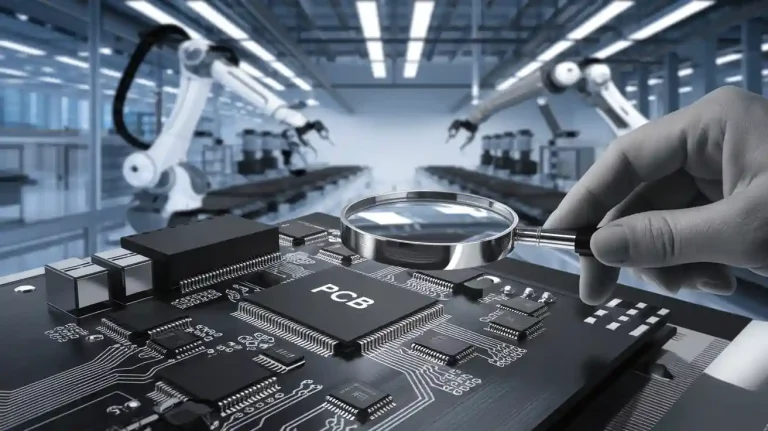

Check the manufacturer’s processes to ensure quality. Look for these practices:

- Incoming Material Check: Confirms raw materials are real and good.

- In-Process Checks: Fixes problems during assembly.

- Automated Optical Inspection (AOI): Spots missing parts or solder mistakes.

- X-Ray Inspection: Finds hidden flaws in solder or layers.

- Functional Testing: Makes sure the PCB works as planned.

These steps show the company cares about quality and your project’s success.

Experience and Expertise in PCB Assembly

Experience matters when picking a PCB service. Skilled manufacturers know how to improve designs and cut costs. Look for these signs of expertise:

| Indicator | Description |

|---|---|

| Engineering Expertise | Engineers help design better layouts and save money. |

| Quality Assurance Rigor | Strong checks like AOI and X-ray to find defects. |

| Effective Communication | Clear talks to avoid mistakes and ensure good results. |

| Continuous Improvement | Regular training and updates to keep high standards. |

| Supply Chain Resilience | Good supplier ties to avoid part shortages. |

Experienced companies use advanced checks like in-circuit testing (ICT). These methods ensure your PCBs are reliable and perform well.

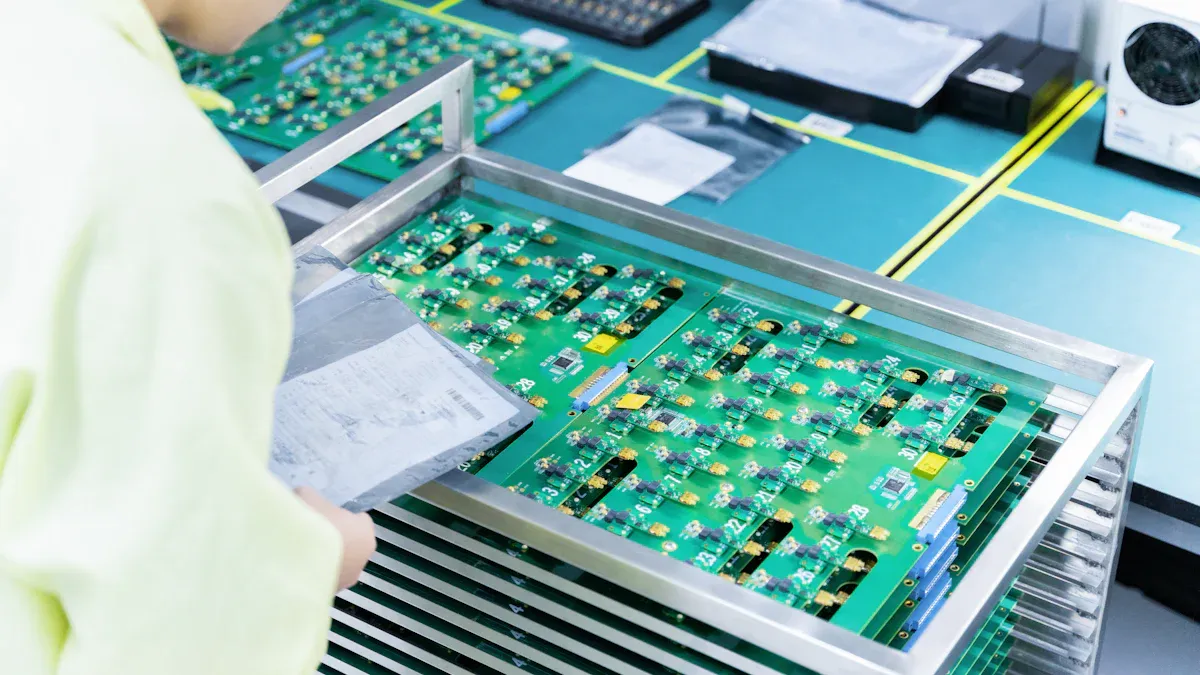

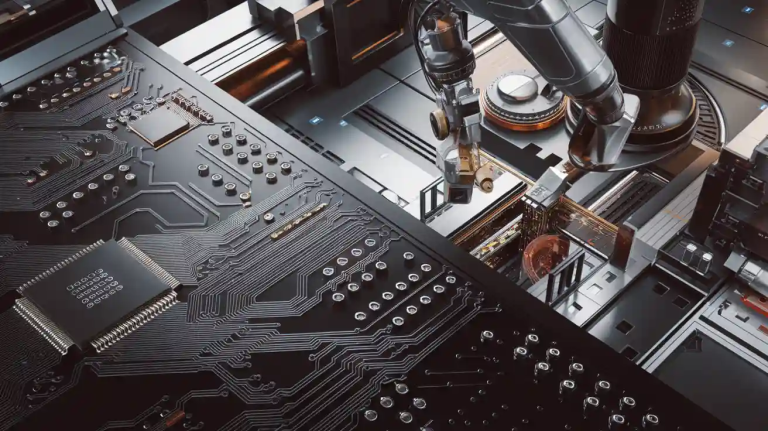

Manufacturing Capabilities and Services

A great PCB manufacturer offers services that fit your needs. Check their skills, production size, and technology. Key things to look for include:

- Production SPC: Tracks machines to keep quality steady.

- Defect Analysis: Finds common issues to fix them quickly.

- Real-Time Testing: Catches problems early to avoid delays.

Companies using new tools and automation work faster and better. For example, improved materials make PCBs stronger and cheaper. Firms like VSE and MCL offer flexible timelines, tech help, and high standards for industries like energy and telecom.

Also, check for order tracking, flexible buying, and good support. A quick-turn PCB maker with these features can meet your needs on time and deliver great results.

Cost Transparency and Value

Picking a PCB assembly company means knowing costs and value. A good partner shows clear prices and helps you get the most for your money. Clear pricing lets you compare costs easily and avoid surprises.

To check cost and value, focus on these money measures:

- Gross Margin and Net Profit: These show how much profit the service makes. Higher margins mean better cost control.

- Direct Material and Labor Costs: Watching these costs shows how they affect production.

- Key Performance Indicators (KPIs): Numbers like production time, yield rate, and usage rate show how well the company works.

For example, a fast PCB maker with few defects saves money on fixes. Companies with turnkey services handle everything, from materials to assembly, for better cost control.

When comparing companies, ask for detailed price lists. Look for clear costs for materials, labor, and extra services like testing. This helps you see the value and match the service to your budget.

Tip: Pick a PCB service that mixes good prices with expert skills. Cheap services may lower quality, but expensive ones aren’t always better.

Customer Support and Communication

Good customer support and clear communication make partnerships successful. A company that cares about customers keeps projects smooth and solves problems fast.

Here’s what to check:

- Response Time: Top PCB makers answer questions quickly, often within two days. This avoids delays and keeps work moving.

- Satisfaction Rate: Choose companies with high customer happiness scores. For example, a 99.28% on-time delivery rate shows they’re reliable.

- Customer Feedback: Happy reviews often mention fast, friendly help and problem-solving.

Clear updates are also important. A good PCB company shares progress, delivery dates, and any issues. They also help with technical problems to meet your goals.

Note: Pick a fast PCB maker with strong communication tools. This helps you make changes quickly and avoid delays.

By focusing on clear costs and good support, you can build a strong partnership. These things improve service value and help your projects succeed long-term.

Questions to Ask a PCB Assembly Company

When picking a good PCB assembly company, asking smart questions helps. It shows if they can meet your needs and match your goals. Here are some key questions to guide you:

What Certifications and Standards Do You Follow?

Certifications show a company cares about quality and safety. A trusted PCB company should follow global rules to make sure your products work well and are safe. Below is a table of important IPC standards and what they mean:

| IPC Standard | Description |

|---|---|

| IPC-A-600 | Explains PCB quality rules like thickness and hole checks. |

| IPC-2222 | Gives tips for designing strong cable harnesses. |

| IPC-D-275 | Shares layout ideas to make PCBs easier to build. |

| IPC-2221 | Lists design rules for working and easy-to-make PCBs. |

| IPC-A-610 | Covers how to check assembly quality for good performance. |

| IPC-1791 | Sets rules for PCBs lasting in tough conditions. |

| IPC-6012 | Details tests and rules for PCB performance. |

These rules improve PCB quality and make production smoother. They also lower risks and build trust with customers. Always check the certifications of the PCB company you’re considering.

Tip: Be careful of companies with unclear or old certifications. Missing rules can hurt your product’s reliability.

Can You Share References or Case Studies?

A company’s past work shows how skilled they are. Ask for examples or stories about their projects. This helps you see if they’ve handled jobs like yours. Look for examples that show:

- Finishing tricky designs or fast PCB projects successfully.

- Solving problems for industries like aerospace or medical fields.

- Results like faster delivery or better quality.

For example, a case study might show how a PCB company cut delivery time by one day while keeping high standards. These stories show how they solve problems and care about customers.

Note: Be cautious if a company won’t share examples or gives vague stories. Honest companies are open about their work.

What Are Your Lead Times and Delivery Processes?

How fast a company works and delivers is very important. Delays can mess up your plans and cost money. To check their delivery skills, think about these:

| Manufacturer | Turnaround Time | Notes |

|---|---|---|

| American Standard Circuits | N/A | Focuses on quality after merging with Sunstone Circuits. |

| Avanti Circuits Inc. | Same-day to 24 hours | Delivers fast without losing quality. |

| JHYPCB | As fast as 24 hours | Known for careful reviews and great speed. |

| JLCPCB | As fast as 24 hours | Budget-friendly for small orders and prototypes. |

| JSD PCB | 48 hours | Offers good service and easy online ordering. |

| PCBWay | 24 hours | Famous for low prices and multilayer options. |

| Rocket PCB | N/A | Specializes in fast PCBs for complex designs. |

| Overseas Manufacturers | As fast as 24 hours | Low prices but may take longer to ship. |

Also, ask about how they improve delivery. For example, some companies save energy by fixing power issues in medical PCBs. Others use smart tools to manage inventory and save money. These ideas make delivery faster and more efficient.

Tip: Pick a fast PCB company with a history of meeting deadlines. Avoid companies with slow or unclear delivery processes.

By asking these questions, you can find a PCB service that fits your needs, ensures quality, and adds value to your business.

How Do You Handle Customization and Prototyping?

Making custom PCBs and testing ideas is very important. A good PCB company should offer flexible options for your needs. They also need to work fast to keep your project on time.

Prototyping means making small batches, usually 1 to 100 units. This helps you test designs before making large amounts. Companies like MPL Incorporated are experts in custom PCB prototypes. They offer services for different needs quickly. For example, MPL can finish most prototype orders in two days. This helps you meet tight deadlines without losing quality.

Here’s a table comparing quick-turn and regular PCB prototyping:

| Metric | Quick Turn PCB | Traditional PCB |

|---|---|---|

| First Pass Yield | 95-98% | 98-99% |

| Defects Per Million Opportunities (DPMO) | 500-1000 | 50-500 |

| On-Time Delivery | 95-98% | 85-95% |

| Average Cycle Time | 1-5 days | 2-6 weeks |

Customization is more than just prototyping. It includes choosing materials, creating layouts, and adding special features. For example, aerospace companies use flexible PCBs made from polyimide for tough conditions. A medical company cut its market time by 40% using custom prototyping while meeting FDA rules.

When choosing a PCB company, ask if they handle custom designs and fast prototyping. Look for companies that are flexible, deliver quickly, and support design changes. These traits help your project succeed and meet industry needs.

What Is Your Approach to Problem Resolution?

Fixing problems well shows a PCB company is reliable. Issues like defects or delays can ruin your schedule and product quality. A good company finds and fixes problems fast to keep things running smoothly.

Top PCB companies use methods like Six Sigma to improve their work. This process finds problems, studies data, fixes causes, and keeps improvements. For example, one company used Six Sigma to raise its first pass yield (FPY) from 95% to 99%, cutting down on waste.

Another tool is Statistical Process Control (SPC). It uses data to find and fix quality issues. For instance, SPC found soldering problems in a factory. Fixing these improved the overall product quality.

Here are ways good PCB companies solve problems:

- Root Cause Analysis: Finding and fixing the main cause of defects.

- Real-Time Monitoring: Using tools to spot problems during production.

- Continuous Improvement: Updating processes to keep quality high.

- Customer Feedback Integration: Listening to customers to improve services.

A strong problem-solving system reduces risks and ensures good PCBs. When picking a PCB company, ask about their problem-solving skills and past success. A company with a good track record will help your projects succeed.

Making the Final Decision

Compare Providers Using Important Factors

When choosing a PCB assembly provider, compare them carefully. This helps you pick one that fits your project’s needs. Use these key performance indicators (KPIs) to evaluate providers:

| KPI | Description |

|---|---|

| Quality and Standards Compliance | Check for quality, attention to detail, and industry certifications. |

| Experience and Expertise | Look at their history and the types of clients they’ve worked with. |

| Capabilities and Services | See if they offer services that help finish your project on time. |

| Testing Options | Make sure they test products for quality and reliability. |

| Turnaround Time and Delivery | Fast delivery avoids delays and extra costs. |

| Cost and Value for Money | Choose a provider that balances good quality with fair pricing. |

Focus on these factors when deciding. Providers with strong testing and on-time delivery records are more reliable. They help avoid problems like delays or poor-quality products.

Match the Choice to Your Business Goals

The PCB service you pick should support your business goals. Check how their services align with what you need by reviewing these metrics:

| Metric | Description |

|---|---|

| Production Cycle Time | Tracks how fast they complete orders, showing efficiency. |

| Defect Rate | Measures how many PCBs have problems, ensuring good quality. |

| On-Time Delivery Rate | Shows how often they deliver on time, building trust with customers. |

| Gross Profit Margin | Reveals profits after production costs, showing cost-effectiveness. |

| Customer Satisfaction Score | Reflects how happy clients are with their products and services. |

For example, if you want faster delivery, choose a provider with short production times and high on-time rates. This keeps your business competitive and efficient.

Test with a Small Order First

Before committing, start with a trial project or small order. This lets you check their skills without big risks. Use different testing methods during this phase to ensure quality:

| Testing Methodology | Benefits |

|---|---|

| In-circuit testing (ICT) | Finds faults quickly, great for large assemblies, reduces errors. |

| Flying probe test | Affordable for prototypes, checks for shorts, resistance, and more. |

| X-ray inspection | Spots hidden defects, checks internal parts and connections. |

| Functional testing | Confirms the prototype works as planned, finds early issues. |

Trial projects also show how well the provider communicates and solves problems. A successful trial proves they can handle bigger, more complex orders.

Tip: If a provider struggles with a small order, they may not be ready for larger projects.

Picking the right PCB assembly service is very important. It helps your business meet goals and succeed. A good provider understands your needs and delivers better results. They also help you save money while keeping high quality, which is key for long-term success.

Spend time figuring out what your project needs. Look at different providers to find the best fit. This careful planning brings more value and helps your business stay creative and flexible. Working with a trusted PCB assembly company helps your business grow and handle industry changes.

Tip: Choose providers who share your goals and focus on quality. This choice will improve efficiency, dependability, and success in the market.

FAQ

What’s the difference between turnkey and consignment PCB assembly?

Turnkey assembly does everything, like buying parts and making boards. Consignment assembly means you provide parts, and they just assemble. Turnkey saves time, while consignment gives you control over parts.

How can I make sure my PCB design works with the manufacturer?

Send your design files to the manufacturer early. Check if their tools match your design needs, like layers or materials. Ask for a design-for-manufacturing (DFM) review to spot problems.

Can I get a prototype before full production?

Yes, most manufacturers make prototypes. Prototypes help test if your design works and find mistakes. Always ask about the time and cost for making prototypes.

What affects how long PCB assembly takes?

Assembly time depends on parts availability, design difficulty, and the company’s workload. Picking a company with good supply chains and clear updates helps avoid delays.

How do I protect my designs with a PCB manufacturer?

Sign a non-disclosure agreement (NDA) before sharing your designs. Choose companies that care about protecting your ideas and use secure systems to keep your data safe.