You rely on advanced electronics every day, from smartphones to satellite communication. SMT PCB boards play a vital role in these systems by delivering high performance and reliability. In aerospace, they ensure satellites operate in extreme conditions and enable modern aircraft to pack more functionality into smaller spaces. Communication systems also benefit from SMT technology, with PCBs powering devices like satellite phones, antennas, and optical transceivers. These innovations highlight how SMT PCBs drive progress in compact, high-frequency designs, ensuring seamless connectivity and robust performance across industries.

Key Takeaways

- SMT PCBs allow small designs, perfect for gadgets like phones and satellites.

- These boards are very reliable and handle tough conditions in space and defense.

- SMT helps send data fast, which is important for 5G and smooth communication.

- Automated SMT assembly lowers costs and makes production more consistent for large amounts.

- SMT PCBs help improve IoT devices, making them connect well and share data quickly.

Overview of SMT PCB Boards and Their Advantages

What Is an SMT PCB Board?

Definition and structure of SMT PCB boards

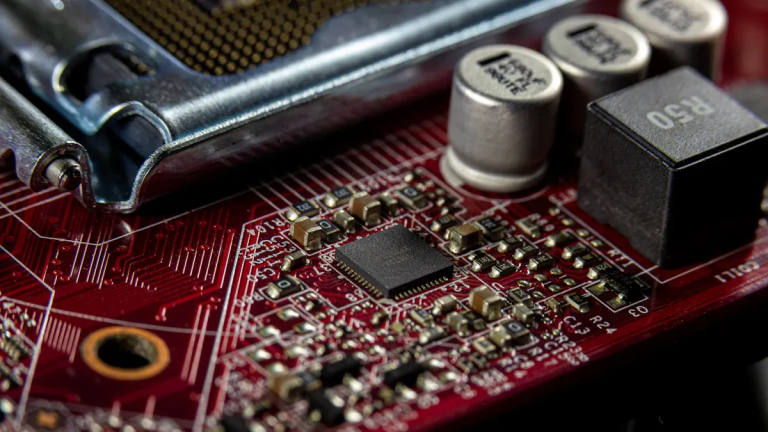

An SMT PCB board, or Surface Mount Technology Printed Circuit Board, is a type of printed circuit board designed for mounting electronic components directly onto its surface. Unlike traditional methods, SMT eliminates the need for drilling holes to attach components. This approach uses solder paste to secure components, creating a compact and efficient design. SMT PCBs often feature multiple layers, enabling complex circuitry in a small footprint.

Key differences from traditional PCB technologies

SMT PCB assembly differs significantly from older through-hole methods. Components in SMT are smaller and lighter, allowing for higher component density. This technology supports miniaturization for portability, making it ideal for modern electronics. Additionally, SMT simplifies automation during manufacturing, reducing production costs and improving consistency. Unlike traditional PCBs, SMT PCBs excel in high-frequency applications due to their shorter leads, which minimize signal loss.

Advantages of SMT PCB Boards

Compact and lightweight design

SMT PCBs enable the creation of smaller and thinner printed circuit boards. This compact design supports miniaturization, which is essential for portable devices like smartphones and wearables. The lightweight nature of SMT PCBs also makes them suitable for aerospace applications, where weight reduction is critical.

High reliability in extreme environments

SMT PCBs offer exceptional reliability. Their robust design withstands extreme temperatures, vibrations, and other harsh conditions. This makes them indispensable in aerospace and defense systems, where durability is non-negotiable.

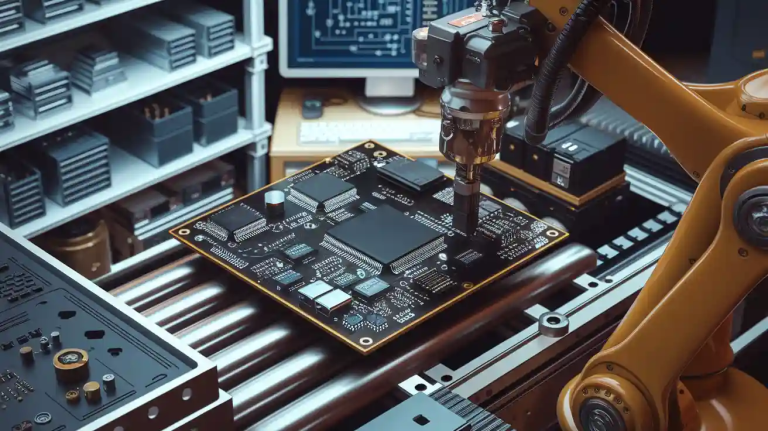

Cost-efficiency in large-scale production

The automated nature of SMT PCB assembly reduces labor costs and increases production efficiency. Automation minimizes human error, ensuring consistent quality across batches. This cost-effective approach makes SMT ideal for mass production of electronics.

Why SMT PCB Boards Are Essential for Aerospace and Communication

Support for high-frequency and high-speed signals

SMT PCBs address challenges like signal distortion and electromagnetic interference. Techniques such as reducing substrate thickness and back drilling improve signal integrity. These features make SMT PCBs perfect for high-speed communication systems.

Enabling miniaturization and complex designs

SMT supports high-density interconnects, allowing intricate designs on multi-layer boards. This capability enhances functionality while maintaining a compact size. The technology also improves electrical performance by reducing inductance and capacitance, ensuring efficient operation in advanced electronics.

Aerospace Applications of SMT PCB Boards

Avionics and Flight Control Systems

Role in navigation, communication, and control systems

SMT PCB assembly plays a critical role in avionics by enabling high-precision flight instruments and reliable communication systems. These PCBs ensure precise control of aircraft movements and support seamless communication between pilots and air traffic controllers. They are essential in navigation equipment like the inertial navigation system (INS) and GPS receiver, which maintain accurate positioning and route planning. SMT technology enhances the performance of these systems by reducing signal interference and improving component density, ensuring compact and efficient designs.

Examples: Autopilot systems, cockpit displays

You can find SMT PCB boards in various avionics systems, including:

- Flight management systems

- Navigation equipment

- Communication systems

- Radar and sensor systems

These PCBs also power autopilot systems, ensuring smooth and automated flight operations. In cockpit displays, SMT PCBs provide high-resolution visuals and reliable data processing, enabling pilots to make informed decisions during flights.

Satellite Communication Systems

Importance in signal processing and data transmission

Satellite communication relies heavily on SMT PCB assembly for its advanced electronics. These PCBs handle signal processing and data transmission with high reliability, even in extreme conditions. SMT technology ensures lightweight and durable aerospace components, making it ideal for satellites. It also supports the development of compact and efficient systems, which are crucial for space missions.

Examples: Transponders, onboard computers

SMT PCBs are integral to devices like transponders and onboard computers. They also power ground station equipment, satellite phones, VSAT terminals, and satellite modems. These applications highlight the versatility of SMT PCBs in satellite communication, ensuring seamless connectivity and robust performance.

Radar and Defense Systems

Use in radar signal processing and targeting systems

Radar systems depend on SMT PCB assembly for their high-frequency signal processing capabilities. These PCBs enhance radar performance by improving sensitivity and reducing interference. This ensures accurate target detection and identification, which is vital for both defense and aerospace applications. SMT technology also reduces the size of radar systems while maintaining their reliability under harsh conditions.

Examples: Military-grade radar, missile guidance systems

In military-grade radar, SMT PCBs improve anti-interference capabilities and ensure precise component installation. Missile guidance systems benefit from the high-density connections provided by SMT technology, enhancing their accuracy and reliability. These features make SMT PCBs indispensable in modern defense electronics.

Space Exploration and Robotics

Applications in spacecraft and robotic systems

Space exploration demands highly reliable and efficient electronic systems. SMT PCB boards fulfill these requirements by enabling critical functions such as communication with Earth, onboard data processing, and navigation systems. These functions ensure that spacecraft operate effectively in the harsh conditions of space. Specialized SMT PCBs are designed to withstand challenges like vacuum exposure, radiation, and extreme temperatures. This makes them indispensable for satellite communication, imaging sensors, and scientific instruments used in space missions.

You can see SMT PCBs in robotic systems as well. Robots used in space exploration rely on these boards for control systems, sensor interfaces, and motor controllers. These components allow robots to perform complex tasks like collecting samples or navigating uneven terrain. SMT technology also supports space-efficient designs, which are crucial for fitting advanced electronics into compact spacecraft and robotic systems.

Examples: Mars rovers, space telescopes

SMT PCB boards power some of the most iconic space exploration systems. For example:

- Mars rovers: These rely on SMT PCBs for navigation, communication modules, and scientific instruments. The boards ensure reliable operation in the extreme environment of Mars.

- Space telescopes: SMT PCBs enable precise control of imaging sensors and data processing systems. This allows telescopes to capture high-resolution images of distant celestial objects.

- Satellite technology: Satellites use SMT PCBs for communication payloads, power management systems, and onboard computers.

- Unmanned Aerial Vehicles (UAVs): These vehicles employ SMT PCBs in flight control systems and payload control units.

These examples highlight the versatility of SMT PCBs in aerospace applications. Their ability to handle extreme conditions and support advanced functionality makes them a cornerstone of modern space exploration.

Applications for PCBs in Communication Systems

5G Infrastructure

Role in base stations and network equipment

You rely on 5G networks for faster data speeds and seamless connectivity. SMT PCB assembly plays a pivotal role in building the infrastructure that powers this technology. Base stations, the backbone of 5G networks, depend on SMT PCBs for high-speed data transmission and low latency. These PCBs handle complex antenna designs and manage heat effectively, ensuring optimal performance. SMT technology also supports the miniaturization of components, enabling compact designs for network equipment.

Examples: Small cell technology, MIMO antennas

SMT PCB boards are essential in various 5G network components, including base stations, repeaters, switches, and routers. Small cell technology, which enhances network coverage in dense urban areas, relies on these PCBs for efficient operation. MIMO (Multiple Input, Multiple Output) antennas, critical for improving signal strength and capacity, also benefit from the high reliability and precision of SMT PCB assembly.

Antennas and Signal Transmission Devices

Use in high-frequency signal processing

Antennas and signal transmission devices require fast and accurate signal processing. SMT PCB assembly ensures this by reducing radio frequency interference and maintaining signal integrity. The compact design of SMT PCBs allows for high-density, multi-layer configurations, which are ideal for high-frequency applications. These features make SMT PCBs indispensable in communication systems where performance and reliability are critical.

Examples: Wi-Fi routers, satellite dishes

You encounter SMT PCBs in everyday devices like Wi-Fi routers and satellite dishes. These PCBs enable faster signal transmission and improved connectivity. Their smaller circuit size and shorter connections enhance overall performance, making them suitable for high-speed telecommunications equipment.

Consumer Communication Devices

Applications in smartphones, tablets, and wearables

SMT PCB assembly drives innovation in consumer electronics by enabling compact and efficient designs. Smartphones, tablets, and wearables rely on these PCBs for their high-speed processors and advanced features. SMT technology supports miniaturization, allowing manufacturers to pack more functionality into smaller devices.

Examples: High-speed processors, compact designs

You can see SMT PCBs in devices like smartphones, where they power high-speed processors and support sleek, lightweight designs. Wearables, such as smartwatches and fitness trackers, also benefit from the compact and reliable nature of SMT PCB assembly. These applications highlight the versatility of SMT PCBs in consumer communication devices.

IoT and Smart Devices

Role in enabling connectivity and data exchange

IoT and smart devices rely on SMT PCBs to enable seamless connectivity and efficient data exchange. These devices require real-time communication to transmit data effectively. High-frequency PCBs play a crucial role by supporting high-speed signal transmission, ensuring reliable performance. You’ll find that wireless connectivity is a cornerstone of IoT systems. SMT PCB assemblies often integrate modules for Wi-Fi, Bluetooth, Zigbee, and cellular technologies, which facilitate communication between devices.

To ensure optimal performance, PCB designers evaluate various communication protocols. For example, Bluetooth and Zigbee are ideal for short-range communication, while Wi-Fi and cellular technologies support long-range connectivity. This versatility allows IoT devices to function in diverse environments, from smart homes to industrial settings. Effective connectivity ensures that IoT devices can exchange data with other systems, enabling automation and smarter decision-making.

Examples: Smart home devices, industrial IoT sensors

SMT PCBs power a wide range of IoT and smart devices. In smart homes, these PCBs are found in devices like thermostats, security cameras, and smart lighting systems. They incorporate sensors such as temperature, motion, and light sensors to gather data. Analog-to-Digital Converters (ADCs) convert this data into digital signals, which the devices process and transmit.

In industrial settings, IoT sensors monitor equipment performance and environmental conditions. SMT PCBs in these sensors include components like voltage regulators for power management and memory devices for data storage. Security modules ensure data protection, while connectors enable physical connections between devices. These features make SMT PCBs indispensable in consumer electronics and industrial applications alike.

By enabling connectivity and supporting advanced functionalities, SMT PCBs drive innovation in IoT and smart devices. Their compact design and high reliability make them a cornerstone of modern electronics.

Comparing SMT PCB Boards with Other Technologies

SMT PCB Boards vs. Through-Hole Technology

Differences in size, performance, and cost

When comparing SMT PCB boards to through-hole technology, you’ll notice significant differences in size, performance, and cost. SMT components are smaller and allow for higher component density, enabling you to maximize the available space on both sides of the PCB. This compact design supports miniaturization, which is essential for modern electronics. SMT assembly relies on automated processes like pick-and-place machines and reflow ovens, making it more cost-effective for high-volume production.

In contrast, through-hole technology uses larger components with leads inserted through drilled holes. These components provide stronger mechanical bonds, making them suitable for applications requiring durability. However, through-hole assembly often involves manual soldering, which increases production costs and limits scalability.

| Aspect | SMT (Surface Mount Technology) | THT (Through-Hole Technology) |

|---|---|---|

| Size | Smaller components, higher density | Larger components, lower density |

| Performance | Better high-frequency performance due to shorter leads | Stronger mechanical bonds, suitable for durability |

| Cost | More cost-effective for high-volume production | More economical for small-scale or prototypes |

Why SMT is preferred for aerospace applications

In aerospace applications, SMT PCB boards offer distinct advantages. Their lightweight nature reduces the overall weight of avionics and satellite systems, which is critical for fuel efficiency and payload capacity. SMT also supports high-density packaging, allowing you to design compact and efficient systems. Additionally, SMT components can withstand extreme conditions, such as high temperatures and vibrations, making them ideal for demanding aerospace environments.

SMT PCB Boards vs. Flexible PCBs

Advantages and limitations of each

Flexible PCBs and SMT PCBs each have unique strengths. Flexible PCBs excel in applications requiring bendable or foldable designs. They are ideal for wearable electronics and devices with limited space. However, flexible PCBs are more expensive to manufacture and may not provide the same level of durability as SMT PCBs.

SMT PCBs, on the other hand, offer better performance in high-frequency applications. They are more cost-effective for large-scale production and provide higher reliability in extreme environments. While they lack the flexibility of their counterparts, SMT PCBs excel in applications requiring compact, rigid designs and robust performance.

Use cases where SMT PCBs excel

You’ll find SMT PCBs outperform flexible PCBs in aerospace and communication systems. For example, they are used in radar systems, satellite communication devices, and avionics. Their ability to handle high-frequency signals and support miniaturization makes them indispensable in these fields.

SMT PCB Boards vs. Hybrid Technologies

Combining SMT with other PCB technologies

Hybrid technologies combine SMT with other PCB methods to optimize performance and functionality. For instance, hybrid PCBs integrate RF and digital designs on a single board, reducing the need for cables and harnesses. This approach enhances reliability, stress resistance, and miniaturization, making it ideal for advanced electronics.

| Feature | Description |

|---|---|

| Hybrid Technology | Combines RF and digital electronic designs on a single PCB. |

| Miniaturization | Reduces overall electronic package size and eliminates cables and harnesses. |

| Reliability | Known for improving reliability in electronic designs. |

| Cost Performance | Offers high cost performance for various applications. |

| Weight and Precision | Light weight and high precision in manufacturing. |

| Stress Resistance | Increases stress resistance in hybrid designs. |

Examples of hybrid applications in aerospace and communication

Hybrid PCBs find applications in various aerospace and communication systems. You’ll see them in flight management systems, radar systems, and satellite communication modules. They also power UAVs, where they enhance flight control, communication, and payload management. These examples highlight how hybrid designs combine the strengths of SMT and other technologies to meet the demands of modern electronics.

SMT PCB boards have revolutionized modern aerospace and communication systems by combining miniaturization, reliability, and high performance. You see their applications in avionics, satellite communication, and 5G infrastructure, where compact designs and advanced technology are essential. SMT assembly enables consumer devices and IoT systems to deliver seamless connectivity and efficiency. As industries demand smaller and more sophisticated electronics, SMT PCB boards will continue to lead innovation. With a projected market growth driven by advancements in automation and 5G, this technology remains indispensable for future developments.

FAQ

1. What makes SMT PCBs better than traditional PCBs?

SMT PCBs offer smaller components and higher density, which allow you to create compact designs. They also support automation during manufacturing, reducing costs and improving consistency. Unlike traditional PCBs, SMT PCBs excel in high-frequency applications due to shorter leads that minimize signal loss.

2. Can SMT PCBs handle extreme environments?

Yes, SMT PCBs are designed for durability. They withstand high temperatures, vibrations, and harsh conditions. This makes them ideal for aerospace and defense systems, where reliability is critical. Their robust design ensures consistent performance even in challenging environments.

3. Why are SMT PCBs important for 5G technology?

SMT PCBs enable high-speed data transmission and low latency, which are essential for 5G networks. They support compact designs for base stations and antennas. Their ability to handle high-frequency signals ensures seamless connectivity and efficient operation in 5G infrastructure.

4. How do SMT PCBs contribute to IoT devices?

SMT PCBs power IoT devices by enabling real-time communication and data exchange. They integrate wireless modules like Wi-Fi and Bluetooth, ensuring connectivity. Their compact design supports miniaturization, making them perfect for smart home devices and industrial IoT sensors.

5. Are SMT PCBs cost-effective for large-scale production?

Absolutely! SMT PCBs rely on automated assembly processes, which reduce labor costs and minimize errors. This makes them highly cost-efficient for mass production. Their scalability ensures consistent quality, making them a preferred choice for manufacturers.

💡 Tip: When designing with SMT PCBs, always consider factors like signal integrity and thermal management to optimize performance.