Choosing the right PCBA maker is crucial, especially when it comes to Mechanical control PCBA. This decision significantly impacts the performance of electronic products. Manufacturers that implement strong quality checks and utilize advanced technology ensure that PCBs are both reliable and accurate. Industries such as automotive, robotics, and manufacturing require sophisticated solutions, making it essential to collaborate with makers capable of producing modern designs.

Quality checks, including Six Sigma and process control, are vital for enhancing product reliability and facilitating the development of superior Mechanical control PCBA designs.

Today’s PCBA manufacturing demands expertise in managing complex designs while adhering to stringent quality standards. This approach ensures that products maintain their quality in a rapidly evolving market.

Key Takeaways

- Picking the right PCBA maker is key for good products.

- Choose makers with top certifications like ISO 9001 and IPC.

- Good communication and support help make PCBA projects successful.

- Pick makers who can handle both small and big orders.

- Long-term partnerships bring trust, better talks, and save money.

Criteria for Picking a Mechanical Control PCBA Maker

Quality Standards and Certifications

Why ISO and IPC Certifications Matter

Certifications like ISO 9001 and IPC are important for judging a PCBA maker. ISO 9001 ensures the company uses a good quality management system. This leads to reliable and consistent products. IPC standards, like IPC-A-600, set rules for PCB quality. These rules make sure all boards meet the same high standards. Such certifications show the maker is serious about quality and follows industry rules.

| Certification/Standard | What It Does | Why It Matters for PCB Making |

|---|---|---|

| ISO 9001 | Sets rules for managing quality. | Ensures steady processes and better products. |

| IPC Standards | Rules for PCB design and assembly. | Ensures boards work well and last long. |

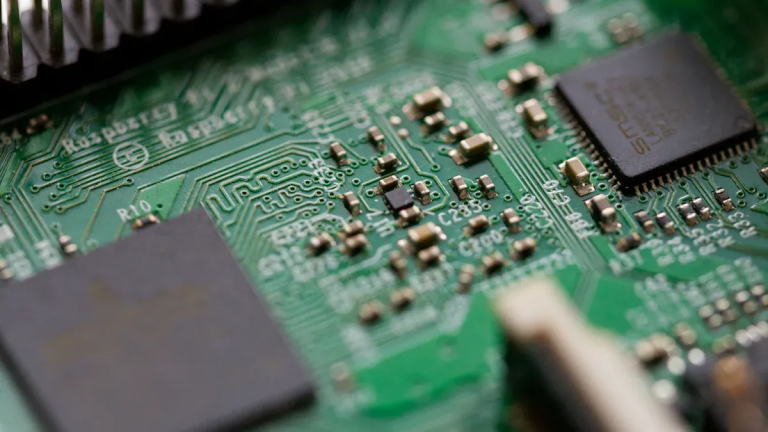

How Quality Control Helps Make Reliable Products

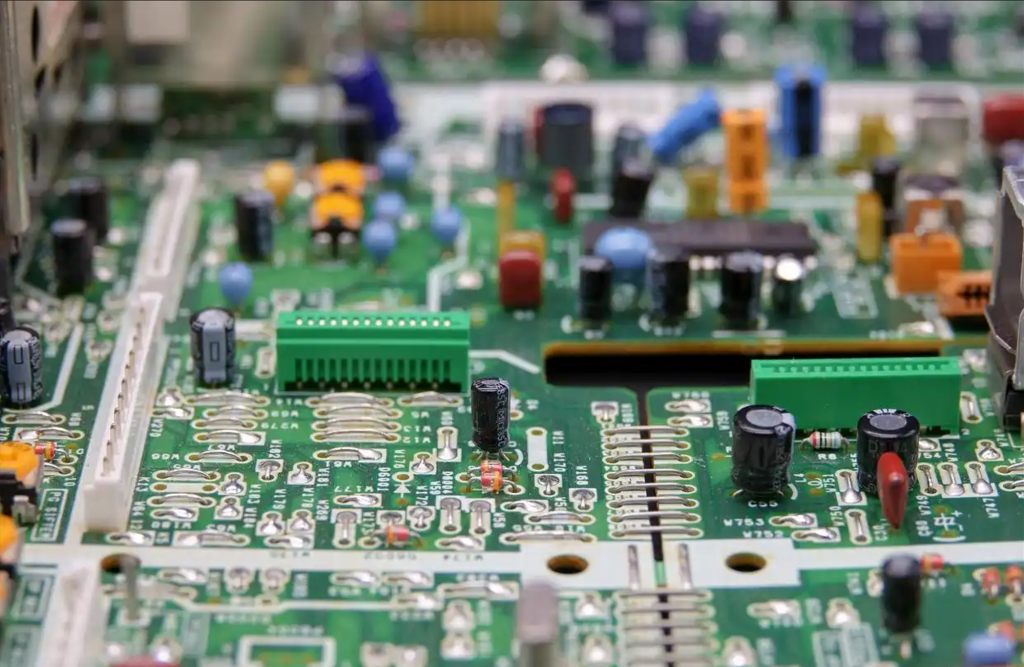

Good quality control, like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT), is key to making great products. AOI spots visible problems, while ICT checks if the board works right. These steps make sure every PCB meets the needed standards. Makers with strong quality checks can create durable and trustworthy boards.

Manufacturing Skills

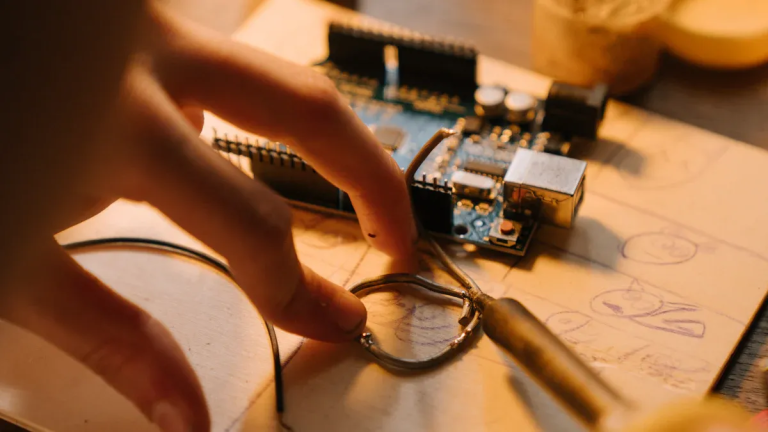

Handling Complex Designs and New Tech

Top PCB makers need skills to handle tricky designs, like high-density boards. They also use new tech, like flexible PCBs and fast prototyping, to meet industry needs. For example, TTM Technologies makes boards with many layers for special uses. This shows how important advanced skills are in PCB making.

Adjusting for Small or Big Orders

Being able to handle both small and big orders is important when picking a PCB maker. Whether it’s a small test run or mass production, the maker should adjust easily. Sanmina Corporation is a good example. They handle both small and large projects well.

Cost and Value

Keeping Costs Low Without Losing Quality

Cost matters, but quality shouldn’t suffer. A good PCB maker keeps costs low by improving processes and using parts wisely. This way, the final product works well without being too expensive.

Saving Money by Choosing Reliable Makers

Working with a trusted PCB maker saves money over time. High-quality boards mean fewer problems, so you spend less on repairs. Also, good supply chains and on-time delivery help projects stay profitable.

| Factor | What It Means | Why It’s Important |

|---|---|---|

| Cost | Total cost to make the product. | Decides if the project is affordable. |

| Quality Checks | Steps to avoid defects. | Ensures the product lasts longer. |

| Delivery Time | How fast products are made and sent. | Affects when you can sell them. |

Picking the right mechanical control PCBA maker means balancing quality, cost, and flexibility. Makers with strong skills and good quality checks provide reliable solutions for many industries.

Customer Support and Communication

Why Clear and Quick Communication Matters

Good communication is key for successful PCBA projects. Factories should share updates and timelines clearly. This helps clients stay informed about progress and any issues. Clear communication builds trust and avoids mistakes that cause delays or extra costs.

Factories with great communication often get good reviews. For example:

- Surveys show they quickly solve customer problems.

- Testimonials praise how fast they fix issues during projects.

- Reviews from industries highlight their reliable communication skills.

By listening to feedback, factories can improve how they communicate. This helps them build stronger relationships with clients. Better communication keeps customers happy and creates lasting partnerships.

Help After the Sale and Warranties

Support after the sale is very important. Control boards often work in tough conditions, so good support is needed. Factories that help with repairs or replacements keep customers satisfied.

Warranties show that a factory cares about quality. A clear warranty gives clients confidence that problems will be fixed. This is especially important in industries like cars and robots, where delays cost money.

Reviews often mention how helpful a factory’s support is. Customers like companies that care even after the sale. This focus on service makes factories stand out in a crowded market.

Good customer support and clear communication are crucial for control board projects. Factories that do well in these areas deliver dependable and top-quality products.

Overview of Top Mechanical Control PCBA Manufacturers

FS Tech. Services

Location and Global Presence

FS Tech. Services is based in Shenzhen, China, with offices in Europe and North America. This setup helps them serve different markets quickly and provide local support.

Key Services and Capabilities

FS Tech. Services makes printed circuit boards (PCBs) for industrial systems. They are skilled in creating HDI PCBs, flexible PCBs, and multi-layer designs. They also offer fast prototyping and small-batch production, making them a top choice for precise and efficient PCB needs.

Unique Advantages

FS Tech. Services invests in advanced research and uses AI-driven tools. This ensures high-quality products and faster delivery times. Their ability to handle complex designs makes them a leader in the PCB industry.

Sierra Circuits

Location and Global Presence

Sierra Circuits is located in Sunnyvale, California, and serves clients across North America and Europe. Being in Silicon Valley helps them stay close to top tech companies and stay competitive.

Key Services and Capabilities

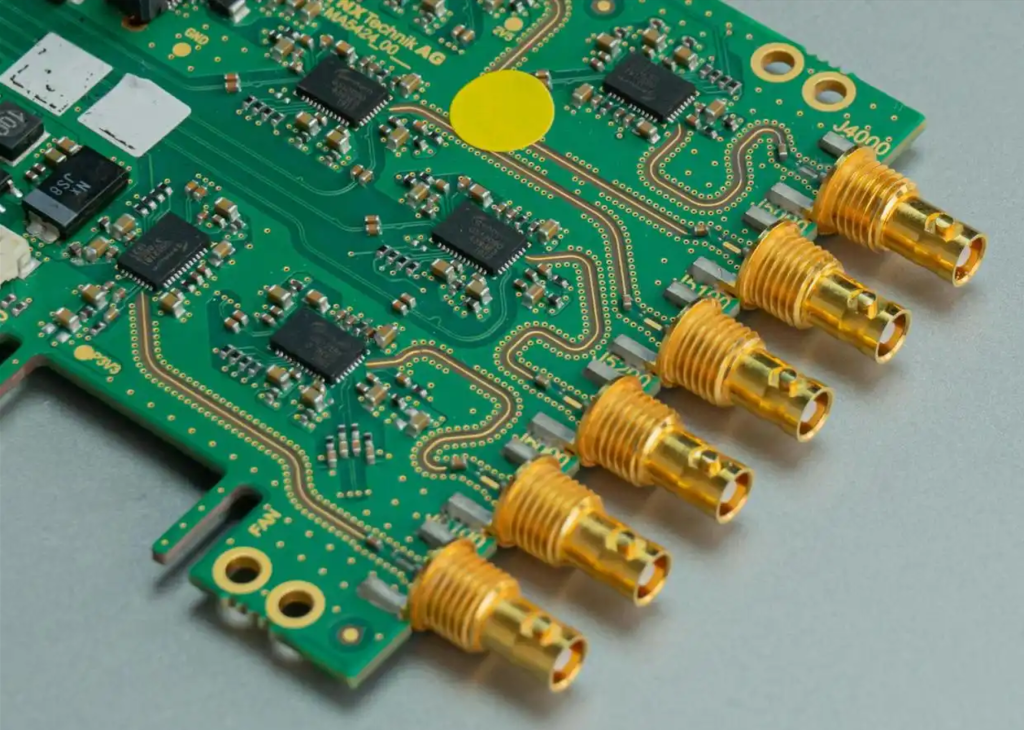

Sierra Circuits provides many PCB services, like rigid-flex PCBs, high-frequency designs, and advanced assembly. They focus on quick-turn manufacturing, delivering products fast without losing quality.

Unique Advantages

Sierra Circuits cares about the environment. They use eco-friendly materials, save water, and recycle waste. They also avoid harmful chemicals and support reusing electronic products.

| Sustainability Practices | What They Do |

|---|---|

| Eco-friendly materials | Use materials that are better for the planet. |

| Optimized water usage | Save water during production. |

| Recycling programs | Reuse materials to cut down on waste. |

| Reduction of hazardous substances | Avoid harmful chemicals in their processes. |

| Promotion of circular economy | Extend the life of electronic products. |

FC (Fulltronics)

Location and Global Presence

Fulltronics is headquartered in Taiwan, with facilities in Southeast Asia and Europe. This wide reach helps them serve industries like automotive, robotics, and automation.

Key Services and Capabilities

Fulltronics offers strong PCB services, including fast assembly, advanced testing, and supply chain management. They handle both small prototypes and large productions, giving clients flexibility.

Unique Advantages

Fulltronics is great at managing supply chains. They work closely with suppliers to keep costs low and deliver on time. Their competitive pricing and adaptability make them a trusted partner for PCB needs.

Fulltronics’ focus on innovation and customer care has made them one of the most reliable PCB makers in the market.

Sanmina Corporation

Location and Global Presence

Sanmina Corporation is a top company in electronics manufacturing. It has factories in many important regions worldwide. This helps it support Original Equipment Manufacturers (OEMs) easily. Sanmina works with industries like communication, cloud services, defense, medical, and cars.

Key Services and Capabilities

Sanmina provides complete solutions for making circuit boards and assemblies. Its Advanced Microsystems Technologies team has over 15 years of experience. They are experts in optical, RF, and microelectronics manufacturing. These skills help meet the demand for modern tech products. Sanmina is trusted for markets like 5G, computing, and industrial systems.

Unique Advantages

Sanmina stands out because of its global reach and experience. It uses advanced technology to make high-quality circuit boards. Its strong processes ensure products meet strict industry needs. This focus on quality makes Sanmina a leader in PCB manufacturing.

Additional Notable Manufacturers

Foxconn

Foxconn is famous for making large amounts of PCBs quickly. It serves industries like electronics and cars, focusing on low costs and fast delivery.

Jabil Inc.

Jabil Inc. is known for its creative solutions in PCB assembly. It works with industries like healthcare, aerospace, and telecom. Jabil also focuses on eco-friendly practices and advanced techniques.

TTM Technologies

TTM Technologies is an expert in high-tech circuit boards. It makes PCBs for industries needing precise and advanced designs, like high-frequency systems.

| Manufacturer | Description |

|---|---|

| TTM Technologies | Known for its expertise in advanced and precise PCB designs. |

| Jabil Inc. | Offers innovative and sustainable PCB assembly solutions. |

| Foxconn | Specializes in large-scale, cost-effective PCB production. |

These companies are leaders in PCB manufacturing, providing reliable solutions for many industries.

Key Features and Innovations Offered by Top Manufacturers

Advanced Technologies

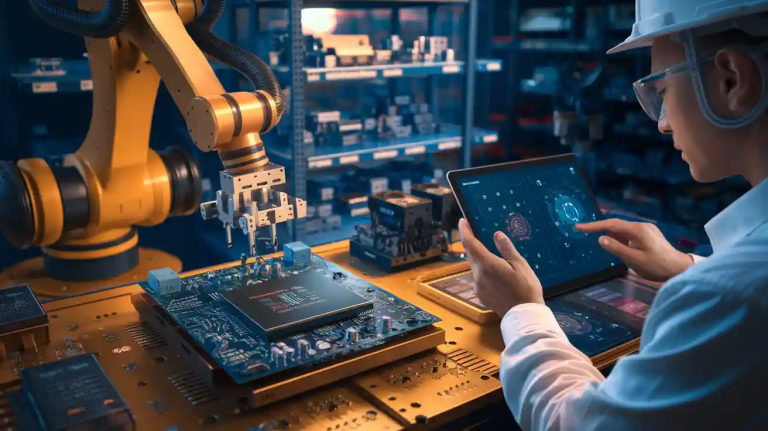

Using AI and Automation in PCB Making

Top manufacturers use AI and machines to improve PCB production. AI tools help design better layouts, reducing mistakes and saving time. Automation speeds up assembly, making products faster and more reliable. For example, AI can predict problems before they happen, cutting downtime and boosting product quality. These tools help meet the need for powerful PCBs in cars and electronics.

Adding IoT and Smart Systems to PCBA Designs

Manufacturers now include IoT and smart systems in their PCBs. IoT PCBs let devices talk to each other, which is useful for smart homes and factories. Special materials and parts make these PCBs stronger and last longer. This is important for industries like aerospace and defense. Flexible PCBs also allow creative designs, helping companies make advanced products.

| Trend/Technology | Description |

|---|---|

| Miniaturization and HDI | Smaller boards with more features using High-Density Interconnect. |

| Flexible and Rigid-Flex PCBs | Boards that bend for unique designs in many industries. |

| Embedded Components | Built-in parts for better performance and durability. |

| AI-Driven PCB Design Automation | AI tools to design faster and with fewer mistakes. |

Supply Chain Management

Why Good Supply Chains Matter

A strong supply chain helps deliver PCBs on time and at low cost. Watching operations closely lets manufacturers fix problems quickly. Sharing clear data builds trust with partners and keeps projects on track. This is especially important for industries like healthcare and cars, where timing is critical.

How Top Makers Deliver on Time and Save Costs

Top companies use smart supply chain methods to meet customer needs. They track things like delivery times, defects, and production speed to stay efficient. By working well with suppliers, they plan better and keep costs down while delivering products on time.

| KPI | Description |

|---|---|

| On-time delivery | Tracks how often orders arrive as scheduled. |

| Defect rates | Counts faulty products in each batch. |

| Lead times | Measures time from order to delivery. |

Research and Development (R&D) Capabilities

How R&D Drives New Ideas

R&D is key to making better PCBs. Companies spend a lot on research to create new tech and improve quality. This helps them meet the needs of industries like healthcare and cars, where accuracy is very important.

Examples of New Tech from Top Makers

Top companies have made big advances through R&D. For instance, eco-friendly PCBs support the push for greener products. High-frequency PCBs are also being made for 5G and IoT uses. These examples show how R&D keeps companies ahead in the market.

Many top manufacturers in North America and Europe focus on R&D. This helps them meet the special needs of different industries.

Tips for Picking the Best Manufacturer for Your Needs

Industry-Specific Needs

Why Choosing an Expert Manufacturer Matters

Manufacturers with industry experience know how to meet special needs. For example, car PCBs must handle heat and shaking. Medical devices need precise designs and follow strict rules. Picking a manufacturer with proven skills ensures your product works well.

Examples of Needs in Different Industries

Each industry has unique PCB needs. Cars need strong and long-lasting boards. Medical devices focus on safety and exact performance. Aerospace requires light but tough designs. Manufacturers must show they can meet these needs with certifications and customer reviews.

| Key Factor | What It Means |

|---|---|

| Customer Reviews | Feedback shows if the manufacturer meets industry standards. |

| Industry-Specific Needs | Different industries like medical or cars have special requirements. |

| Quality Checks | Strict quality steps are vital for regulated industries. |

Protecting Intellectual Property (IP)

Keeping Designs Safe and Private

Protecting your designs is very important when working with manufacturers. Companies should make sure their ideas stay private during production. Manufacturers with strong IP rules and secure systems give clients peace of mind.

Questions to Ask About IP Safety

When choosing a manufacturer, ask about their IP policies. For example:

- How do they keep design files safe?

- What steps stop others from accessing private data?

- Do they have a good record of keeping client info secure?

These questions help you know if the manufacturer values security and respects your rights.

Growth and Long-Term Partnerships

Can the Manufacturer Grow With Your Business?

If your business grows, the manufacturer should handle more orders. They need flexible processes and advanced tools to meet bigger demands without losing quality.

Why Long-Term Partnerships Are Helpful

Working with the same manufacturer over time has benefits. Trust and better communication develop with regular collaboration. Manufacturers also learn your needs, making production faster and better. Long-term deals can save money with bulk discounts and smoother processes.

Picking the right PCBA manufacturer means checking their skills, IP safety, and ability to grow. Focusing on these points ensures reliable products and lasting success.

Picking the right mechanical control PCBA maker is very important. It helps make products reliable, creative, and able to grow with demand. Makers with good quality checks, new technology, and great support stand out. They are useful for industries like cars and robots. Companies like FS Tech. Services, Sierra Circuits, and Sanmina Corporation show these strengths. They offer custom solutions for different needs. Checking makers for skills, growth ability, and lasting value helps businesses grow steadily. Choosing carefully ensures strong products that meet needs and lead to success.

FAQ

What is an industrial control board?

An industrial control board is a special PCB used in factories. It helps manage machines and automate tasks. It connects sensors, controllers, and actuators to make systems like robotics and energy work smoothly.

Why are quality certifications important for industrial control boards?

Certifications like ISO 9001 and IPC prove high-quality standards. They ensure the boards work well, last long, and meet industry rules. This is very important for industrial use.

How do manufacturers ensure the durability of industrial control boards?

Manufacturers use strong materials and test the boards carefully. They add protective layers and check for heat and vibration resistance. These steps make sure the boards survive tough conditions.

What industries commonly use industrial control boards?

Industries like cars, robots, planes, and energy depend on these boards. They help with automation and accuracy in tasks like power control and assembly lines.

How can businesses choose the right manufacturer for industrial control boards?

Businesses should check if the maker has certifications and good customer service. Look for experience in your industry and a history of reliable products.

Tip: Ask for samples and read reviews before choosing a manufacturer.