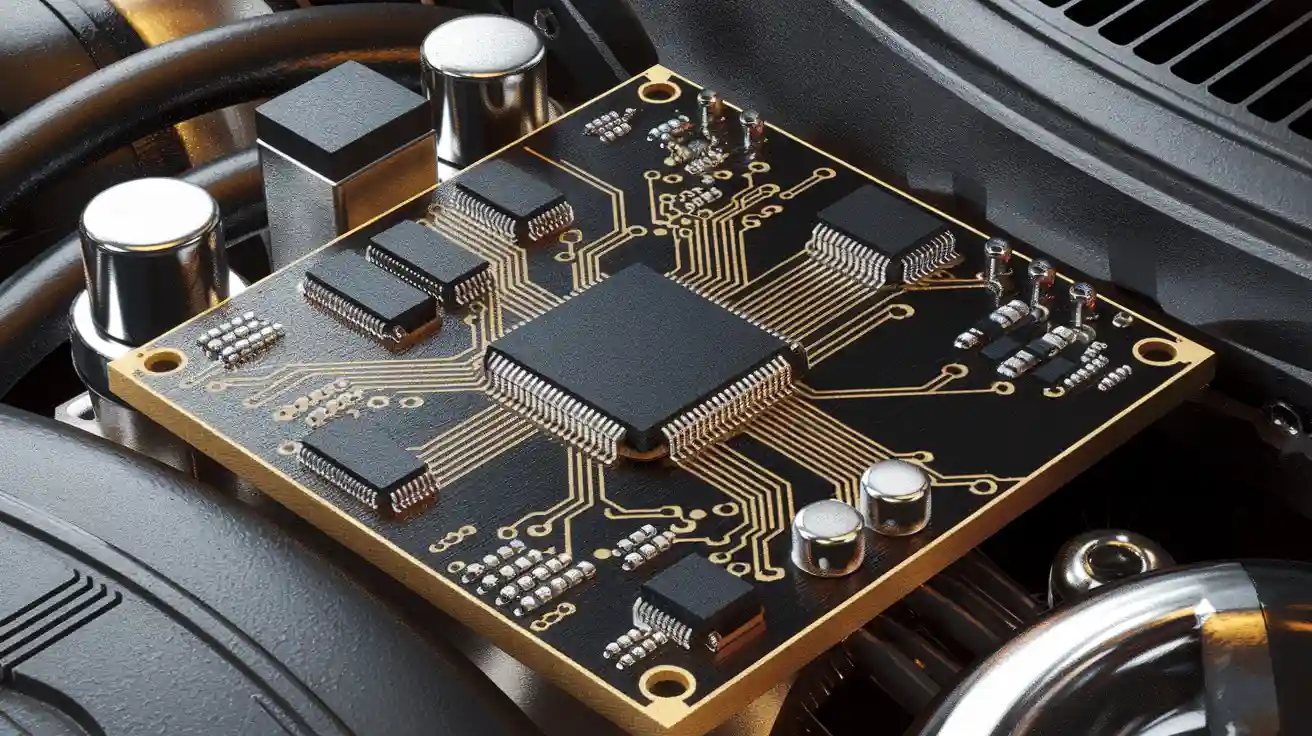

When it comes to automotive electronics, the materials used in automotive PCBs play a critical role in ensuring reliability and safety. You need materials that can withstand high temperatures, resist moisture, and perform under extreme conditions. For instance, FR-4 offers an excellent balance of cost and performance, making it a popular choice in the automotive PCB market. Polyimide excels in high-temperature environments, while PTFE is ideal for advanced communication systems due to its low dielectric constant. Choosing the right material ensures your automotive PCB delivers consistent performance, even in the most demanding applications.

Key Takeaways

- Choose materials like FR-4 for affordable and reliable car PCBs.

- Use polyimide or ceramic for heat-resistant PCBs that last longer.

- Focus on good heat flow to stop overheating and protect parts.

- Follow rules like IPC-6012DA and AEC-Q100 for safe PCBs.

- Work with skilled PCB makers to pick the right materials easily.

Overview of Automotive PCB Requirements

Environmental Challenges in Automotive Applications

Automotive environments are unforgiving. Your automotive PCB must endure constant exposure to extreme conditions. Temperature fluctuations, for instance, can range from sub-zero levels to over 150°C, depending on the vehicle’s location and operation. These variations can compromise performance and structural integrity if the wrong materials are used. Vibrations and shocks from rough roads or high-speed driving also test the mechanical strength of your PCB. Without proper material selection, these stressors can lead to cracks or delamination.

Moisture is another critical factor. High humidity or water exposure can cause corrosion or short circuits. To combat this, you need materials with low moisture absorption rates. Effective thermal management is equally vital. Overheating can damage components, so high thermal conductivity materials are essential for heat dissipation. By addressing these challenges, you ensure your automotive PCB technology performs reliably in any environment.

Reliability and Durability in Harsh Conditions

Reliability is non-negotiable in the automotive industry. Your PCB must meet high reliability standards to ensure safety and performance. Standards like ISO 26262 focus on rigorous safety analysis, reducing the risk of critical failures. Similarly, IPC-6012DA ensures robust manufacturing processes, while AEC-Q100 and AEC-Q200 establish uniform testing protocols for components under stress.

| Standard | Purpose | Impact on Reliability |

|---|---|---|

| ISO 26262 | Ensures rigorous safety analysis and hazard mitigation | Reduces likelihood of safety-critical failures |

| IPC-6012DA | Sets requirements for manufacturing and performance of rigid PCBs | Ensures consistent reliability and robustness |

| AEC-Q100 to AEC-Q200 | Establishes uniform testing protocols for automotive components | Ensures consistent performance under stress conditions |

Durability is equally important. Automotive PCBs must withstand vibrations, shocks, and prolonged use without degradation. This durability ensures your PCB remains functional throughout the vehicle’s lifespan, even in harsh conditions.

Electrical and Thermal Performance Needs

Electrical and thermal performance are at the core of automotive PCB technology. Stable dielectric properties are crucial for reliable signal transmission, especially in advanced systems like ADAS (Advanced Driver Assistance Systems). High thermal conductivity materials help dissipate heat, preventing overheating and ensuring consistent performance.

Copper weight also plays a significant role. Thicker copper layers improve current-carrying capacity, which is essential for power-intensive applications. Mechanical strength further enhances durability, allowing your PCB to endure physical stress without compromising performance. By prioritizing these factors, you meet the reliability requirement on PCBs and ensure high reliability in your designs.

Key Automotive PCB Materials

FR-4: Versatile and Cost-Effective

FR-4 is one of the most widely used materials in the automotive PCB market. Its popularity stems from its versatility and cost-effectiveness. You can rely on FR-4 for applications that require a balance between performance and affordability. This material offers excellent mechanical strength and electrical insulation, making it suitable for a variety of automotive systems, including infotainment and basic control modules.

FR-4 also provides moderate thermal resistance, which works well for low to medium power applications. Its ability to maintain structural integrity under moderate thermal and mechanical stress ensures reliable performance in standard automotive environments. If you’re looking for a dependable and budget-friendly option, FR-4 is a solid choice.

Polyimide: High-Temperature Resistance

When your automotive PCB needs to operate in extreme heat, polyimide is the material you should consider. High-temperature polyimide materials exhibit exceptional thermal stability and mechanical strength, which are critical for automotive applications. They maintain high dielectric strength and a low dissipation factor, ensuring reliable electrical insulation even in extreme heat.

Polyimide materials are designed to retain their electrical properties across a wide temperature range. This makes them ideal for high-temperature environments, such as under-the-hood applications or powertrain systems. By choosing polyimide, you ensure your PCB delivers consistent performance where other materials might fail.

Metal-Core PCBs: Enhanced Thermal Management

For applications requiring superior thermal management, metal-core PCBs are unmatched. These PCBs, often made with aluminum cores, excel in dissipating heat efficiently. Here’s why they stand out:

- Unmatched Thermal Conductivity: Aluminum PCBs offer a thermal conductivity of around 200W/m·K, far exceeding that of standard FR-4 boards.

- Dramatically Lower Operating Temperatures: Components on aluminum PCBs experience junction temperature reductions of 20°C to 30°C, enhancing their reliability.

- Higher Power Handling Capacity: These PCBs support high-power applications, such as high-brightness LEDs, which can safely operate at over 10W per LED.

- Minimized Thermal Resistance: Their construction ensures low thermal resistance, maximizing cooling performance.

- Low Weight yet Durable: Aluminum PCBs are lightweight and durable, making them ideal for automotive systems that face constant vibrations.

By incorporating metal-core PCBs into your designs, you can achieve superior heat dissipation and ensure the longevity of your automotive electronics.

Ceramic Substrates: Superior Heat Resistance

Ceramic substrates are a game-changer for automotive PCBs, especially in high-temperature environments. These materials excel in applications where extreme heat is a constant challenge, such as under-the-hood systems or powertrain electronics. By choosing ceramic substrates, you ensure your automotive electronics remain reliable and efficient, even in the harshest conditions.

- Exceptional Heat Resistance: Ceramic substrates can endure temperatures far beyond the capabilities of traditional PCB materials. This makes them ideal for electronic control units (ECUs) and other critical systems that operate in high-temperature zones.

- Enhanced Safety and Durability: These materials improve the safety of automotive electronics by maintaining performance under thermal stress. They also extend the lifespan of your PCBs, reducing the risk of failure over time.

- Improved Efficiency: With their ability to handle extreme heat, ceramic substrates contribute to the overall efficiency of automotive systems, ensuring consistent operation in demanding environments.

When you incorporate ceramic substrates into your designs, you’re investing in the durability and performance of your automotive PCBs. This choice not only enhances reliability but also positions your products as leaders in the competitive automotive PCB market.

Flexible PCBs: Adaptability in Design

Flexible PCBs offer unmatched versatility, making them a top choice for modern automotive applications. Their ability to bend, twist, and conform to unique shapes allows you to create innovative designs that were previously impossible with rigid boards.

- Seamless Integration: Flexible PCBs are perfect for tight spaces and complex geometries. For instance, in a leading autonomous vehicle project, engineers used flexible PCBs to create a conformal sensor array. This design fit seamlessly into the vehicle’s aerodynamic structure, enhancing detection capabilities.

- Miniaturization: Flexible PCBs enable you to reduce the size of electronic control units. In one prototype, these PCBs allowed for better integration and performance optimization within the vehicle’s architecture.

- Durability in Motion: These PCBs can withstand constant vibrations and movement, making them ideal for automotive systems that experience frequent mechanical stress.

By leveraging flexible PCBs, you can push the boundaries of design and functionality. Their adaptability ensures your automotive electronics meet the demands of modern vehicles while maintaining high performance and reliability.

Performance Properties of Automotive PCBs

Thermal Conductivity and Heat Dissipation

Thermal conductivity is a critical factor in the performance properties of automotive PCBs. You need materials that can efficiently dissipate heat to prevent overheating and ensure long-term reliability. The substrate and copper conductors play a significant role in heat movement. By estimating thermal conductivity, you can predict temperature rises in components and implement effective thermal management strategies. For example, using a weighted average of material properties helps calculate thermal resistance, which is essential for maintaining optimal operating temperatures in automotive systems.

High thermal conductivity materials, such as metal-core PCBs, excel in dissipating heat. These materials reduce the risk of thermal damage, especially in power-intensive applications like LED lighting or electric vehicle systems. By prioritizing heat dissipation, you enhance the durability and safety of your automotive electronics.

Dielectric Constant and Insulation

The dielectric constant of PCB materials directly impacts insulation and signal integrity. You must select materials with appropriate dielectric properties to meet the basic requirement on performance. For instance, low dielectric constant materials minimize signal losses at high frequencies, improving insulation and reducing crosstalk. This is particularly important in advanced automotive systems like ADAS, where signal clarity is crucial.

PCB substrates act as dielectric layers, insulating copper conductors and preventing short circuits. Materials like PTFE offer excellent charge storage but may increase dielectric loss. Balancing these properties ensures your automotive PCB delivers reliable performance without compromising insulation.

| Material | Dielectric Constant | Insulation Properties |

|---|---|---|

| PTFE | High | Excellent charge storage, potential for loss |

| Filled PTFE | Moderate | Balanced performance with reduced crosstalk |

Coefficient of Thermal Expansion (CTE)

Matching the coefficient of thermal expansion (CTE) between PCB materials and components is vital for reliability. Materials like direct bond copper (DBC) and direct bond aluminum (DBA) are designed with lower CTE values to align with semiconductor materials like Gallium Nitride (GaN) and Silicon Carbide (SiC). This alignment reduces stress during thermal cycling and high-temperature conditions, ensuring your automotive PCB remains durable.

By choosing materials with compatible CTE values, you prevent issues like delamination or cracking, which can compromise performance. This approach is especially important in the automotive PCB market, where reliability under extreme conditions is non-negotiable.

Corrosion Resistance and Surface Finishes

Corrosion is one of the biggest threats to the longevity of your automotive PCBs. Exposure to moisture, chemicals, and temperature fluctuations can lead to oxidation and material degradation. This weakens the PCB and compromises its performance. To combat this, you need to prioritize corrosion resistance when selecting materials and finishes for your designs.

Surface finishes play a critical role in protecting your PCBs from corrosion. They act as a barrier, shielding the copper layers from environmental damage. Popular options include ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative). Each finish offers unique benefits:

- ENIG: Provides excellent corrosion resistance and a smooth surface for soldering. It’s ideal for high-reliability automotive applications.

- HASL: A cost-effective option that offers decent protection but may not suit high-density designs.

- OSP: Environmentally friendly and suitable for short-term protection, but less durable in harsh conditions.

Choosing the right finish depends on your application. For instance, under-the-hood systems require robust finishes like ENIG to withstand extreme heat and humidity. On the other hand, infotainment systems may perform well with simpler finishes like OSP.

Investing in corrosion-resistant materials and finishes ensures your PCBs remain reliable throughout the vehicle’s lifespan. This not only enhances performance but also positions your products as leaders in the competitive automotive PCB market. By making the right choices, you protect your designs from failure and gain a significant edge in the automotive industry.

Tip: Consult with your PCB manufacturer to determine the best surface finish for your specific automotive application.

Automotive PCB Design Considerations

PCB Thickness and Layer Count

When designing automotive PCBs, you must carefully consider the thickness and layer count. These factors directly impact the board’s durability, thermal performance, and ability to handle complex circuitry. Thicker PCBs with multiple layers provide enhanced structural integrity, making them ideal for withstanding the vibrations and shocks common in automotive environments. This is especially important for under-the-hood applications, where extreme conditions are the norm.

- Thermal Management: A thicker PCB can incorporate advanced thermal management features, such as heat sinks or thermal vias, to dissipate heat effectively. This prevents overheating and extends the lifespan of automotive PCB components.

- Durability: Reinforced structures absorb mechanical stress, ensuring the PCB remains intact during thermal cycling and vibration testing.

- Complex Circuitry: Multi-layer designs allow for more intricate routing, supporting advanced automotive systems like ADAS and electric vehicle powertrains.

By optimizing thickness and layer count, you ensure your PCB meets the rigorous demands of the automotive PCB market.

Copper Weight and Conductivity

Copper weight plays a crucial role in determining the electrical performance of your automotive PCB. Heavier copper layers improve current-carrying capacity, making them essential for power-intensive applications like electric vehicles and high-performance lighting systems. You should prioritize copper weights that balance conductivity and durability to ensure reliable performance.

- Enhanced Conductivity: Thicker copper layers reduce resistance, ensuring stable power delivery across the board. This minimizes voltage drops and electromagnetic interference, which are critical for maintaining signal integrity.

- Thermal Benefits: Copper’s excellent thermal conductivity aids in heat dissipation, protecting sensitive components from damage.

- Durability: Heavier copper layers also enhance the mechanical strength of the PCB, allowing it to withstand harsh automotive conditions.

Selecting the right copper weight ensures your automotive PCB design delivers consistent performance and reliability.

Component Placement and Layout

The placement of components on your PCB significantly affects its overall performance. Strategic layout optimization enhances signal integrity, power distribution, and thermal management, ensuring your design meets the high standards of the automotive industry.

- Signal Integrity: Proper routing and impedance control maintain accurate data transmission, especially in electric vehicles.

- Power Distribution: Robust networks reduce voltage drops and electromagnetic interference, ensuring stable power delivery to all components.

- Thermal Management: Advanced techniques like thermal vias and heatsinks dissipate heat efficiently, extending component longevity.

- Manufacturability: Optimized layouts streamline production processes, reducing costs and improving innovation potential.

By prioritizing these design considerations, you create a PCB that performs reliably in demanding automotive applications.

Testing and Prototyping for Validation

Testing and prototyping are essential steps in validating your automotive PCB designs. These processes ensure your PCBs meet the rigorous demands of the automotive industry and perform reliably in real-world conditions. By investing in thorough validation, you can avoid costly failures and deliver high-quality products.

Prototyping allows you to create a functional model of your PCB design. This step helps you identify potential issues early, saving time and resources. For example, you can test the PCB’s ability to handle extreme temperatures, vibrations, and thermal cycling. These tests simulate the harsh conditions your PCB will face in automotive applications. By addressing weaknesses during prototyping, you can refine your design before moving to mass production.

Testing goes hand-in-hand with prototyping. It provides critical insights into the durability and performance of your PCB. Key aspects of testing include:

- Endurance under Stress: Ensures your PCB withstands extreme temperatures, thermal cycling, and mechanical vibrations.

- Predicting Component Lifespan: Helps estimate how long components and solder joints will last under stress.

- Failure Mode Analysis: Identifies weak points and failure modes, enabling you to make informed design improvements.

- Quality Assurance: Confirms that only robust PCBs are used in your automotive systems.

| Key Aspect | Description |

|---|---|

| Endurance under Stress | Ensures automotive PCBs can withstand extreme temperatures, thermal cycling, and mechanical vibrations. |

| Predicting Component Lifespan | Helps estimate the lifespan of components and solder joints through thermal stress and vibrations. |

| Failure Mode Analysis | Identifies failure modes and weak points, enabling informed design improvements before mass production. |

| Quality Assurance | Serves as a quality assurance measure, ensuring only robust PCBs are used in automotive systems. |

By combining prototyping and testing, you can confidently validate your designs. This approach not only ensures reliability but also strengthens your position in the competitive automotive PCB market. Don’t overlook these critical steps—they are your key to delivering durable and high-performing automotive electronics.

Tip: Collaborate with experienced PCB manufacturers to streamline your testing and prototyping processes. Their expertise can help you achieve faster validation and better results.

Industry Standards for Automotive PCBs

IPC-6012DA: Rigid PCB Addendum

When designing automotive PCBs, adhering to IPC-6012DA standards ensures your boards meet the highest levels of reliability and safety. This addendum outlines specific requirements for rigid PCBs used in automotive applications, focusing on durability and consistent performance. By following these guidelines, you can create PCBs that withstand the harsh conditions vehicles face daily.

- Safety Assurance: IPC-6012DA aligns with ISO 26262, ensuring rigorous safety analysis. This helps you identify potential hazards and implement effective risk mitigation strategies.

- Reliability Enhancement: The standard emphasizes robust manufacturing processes, reducing the likelihood of PCB failures. This is crucial for maintaining high reliability in automotive systems.

- Consistent Performance: IPC-6012DA works in conjunction with AEC-Q100 and AEC-Q200 standards, ensuring your PCBs perform reliably under stress conditions like extreme temperatures and vibrations.

By complying with IPC-6012DA, you not only enhance the reliability of your PCBs but also gain a competitive edge in the automotive PCB market.

AEC-Q100: Automotive Component Qualification

AEC-Q100 sets the benchmark for testing and qualifying automotive components. This standard ensures your PCBs and their components can handle the demanding conditions of automotive environments. It focuses on stress testing to verify performance and durability.

| Standard | Description |

|---|---|

| AEC-Q100 | A failure mechanism-based stress test qualification for packaged integrated circuits, outlining qualification requirements and procedures for automotive applications. |

| IEC60664-1 | Focuses on the dimensioning of clearances to withstand maximum peak voltage across air gaps, essential for high-altitude applications. |

| VDE0884-10 | Concerns maximum transient voltages a device can withstand without breakdown, based on partial discharge tests. |

| CTI 600 Mold Material | Measures the electrical breakdown properties of insulating materials, crucial for ensuring safety and reliability in automotive components. |

By adhering to AEC-Q100, you ensure your components meet the rigorous demands of automotive PCB standards. This not only boosts reliability but also positions your products as trustworthy solutions in the automotive industry.

RoHS and REACH Compliance

RoHS and REACH compliance are essential for producing environmentally friendly and safe automotive PCBs. These regulations restrict the use of hazardous substances and promote sustainable manufacturing practices. By adhering to these standards, you protect both the environment and the end-users of your products.

| Aspect | Description |

|---|---|

| RoHS Compliance | Restricts hazardous materials in electronic products, enhancing safety and minimizing environmental impact. |

| Safety Regulations | Ensures materials meet safety standards, reducing risks associated with toxic substances. |

| Sustainability Practices | Supports eco-friendly manufacturing through responsible material choices. |

| Benefits of Compliance | Enhances safety, contributes to sustainability, and ensures alignment with global regulations. |

Complying with RoHS and REACH not only ensures your PCBs meet global safety standards but also demonstrates your commitment to sustainability. This compliance can significantly enhance your reputation in the automotive PCB market.

Tip: Partner with manufacturers who prioritize RoHS and REACH compliance to streamline your production process and ensure adherence to these critical standards.

ISO/TS 16949: Quality Management Standards

ISO/TS 16949 stands as the gold standard for quality management in the automotive industry. If you want to ensure your automotive PCBs meet the highest levels of quality and reliability, this certification is non-negotiable. It focuses on creating a systematic approach to manufacturing, ensuring every step of the process delivers consistent results.

This standard emphasizes defect prevention and continuous improvement. By adopting ISO/TS 16949, you can minimize production errors and reduce waste. This not only saves costs but also enhances the overall quality of your PCBs. For example, if you’re producing PCBs for electric vehicles, adhering to this standard ensures your boards can handle the rigorous demands of high-performance systems.

ISO/TS 16949 also strengthens your position in the competitive automotive PCB market. Many leading manufacturers and suppliers require this certification as a prerequisite for partnerships. By meeting these standards, you demonstrate your commitment to quality and reliability, making your products more appealing to potential clients.

The certification process involves rigorous audits and assessments. These evaluations cover everything from material sourcing to final product testing. By passing these audits, you prove that your processes align with global best practices. This gives you a significant edge in the automotive industry, where reliability and safety are paramount.

Tip: Partner with a PCB manufacturer that already complies with ISO/TS 16949. This ensures your designs meet industry standards without additional hassle.

By prioritizing ISO/TS 16949, you not only improve the quality of your automotive PCBs but also build trust with your customers. This certification is more than a requirement—it’s a commitment to excellence that sets you apart in the automotive industry.

Tips for Choosing Automotive PCB Materials

Evaluating Application-Specific Needs

Choosing the right material for your automotive PCB starts with understanding the specific needs of your application. Each material offers unique advantages tailored to different automotive systems. For example:

| Material | Advantages | Applications |

|---|---|---|

| FR-4 | Excellent balance of performance and cost, decent mechanical strength. | Standard automotive applications. |

| Polyimide | Superior thermal resistance and flexibility, maintains performance under extreme temperatures. | Flexible PCBs in dynamic environments. |

| PTFE | Low dielectric constant, excellent thermal characteristics. | High-frequency applications in modern vehicles. |

By matching material properties to your application, you ensure optimal performance and reliability. For instance, if your design involves high-frequency communication systems, PTFE is an excellent choice. On the other hand, polyimide works best for under-the-hood systems exposed to extreme heat. This careful evaluation not only enhances reliability but also aligns your design with the demands of the automotive PCB market.

Balancing Cost and Performance

Striking the right balance between cost and performance is crucial in automotive PCB manufacturing. While premium materials like ceramic substrates offer unmatched heat resistance, they may not be necessary for all applications. Instead, consider materials like FR-4, which provide a cost-effective solution for standard automotive systems without compromising reliability.

You should also factor in long-term benefits. Investing in high-quality materials may seem expensive initially, but it reduces the risk of failures and extends the lifespan of your PCBs. This approach minimizes maintenance costs and enhances customer satisfaction. By balancing cost and performance, you create a product that meets both budgetary constraints and performance expectations.

Tip: Collaborate with automotive PCB suppliers to explore material options that fit your budget while meeting your performance goals.

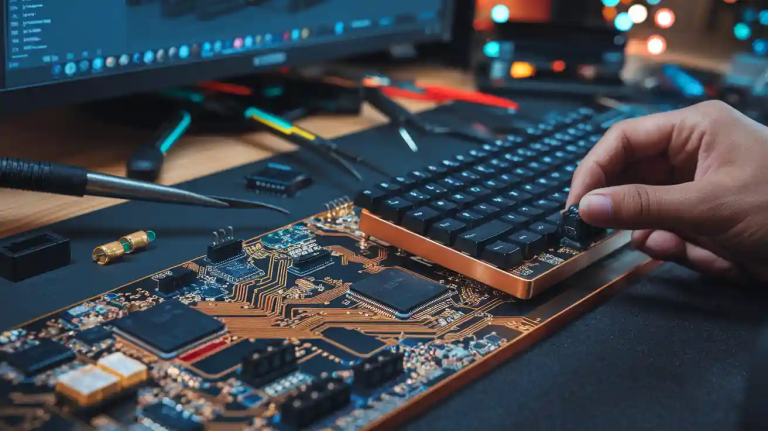

Consulting with PCB Manufacturers

Partnering with experienced PCB manufacturers is one of the smartest moves you can make. These experts bring valuable insights into material selection, design considerations, and manufacturing features of automotive PCBs. They can guide you in sourcing materials that meet industry standards and ensure reliability.

Effective strategies include establishing long-term relationships with suppliers to secure a steady supply of components. You can also design your PCBs to accommodate alternative materials, reducing the risk of supply chain disruptions. Open communication with manufacturers helps you anticipate potential issues and address them proactively.

By consulting with manufacturers, you gain access to their expertise and resources. This collaboration not only streamlines the manufacturing process but also ensures your automotive PCB design meets the highest standards of quality and reliability.

Ensuring Compliance with Standards

Ensuring compliance with industry standards is essential for creating reliable and safe automotive PCBs. These standards validate your designs and demonstrate your commitment to quality, safety, and performance. By adhering to established guidelines, you can meet customer expectations and gain a competitive edge in the automotive PCB market.

Several key standards guide the manufacturing and testing of automotive PCBs. ISO 26262 ensures rigorous safety analysis, helping you identify hazards and implement risk mitigation measures. IPC-6012DA outlines specific requirements for rigid PCBs, enhancing their reliability and quality. AEC-Q100 and AEC-Q200 establish uniform testing protocols, ensuring consistent performance under stress conditions. These standards collectively ensure your PCBs meet the high demands of automotive applications.

Testing plays a critical role in validating compliance. Thermal cycling evaluates your PCB’s ability to endure temperature fluctuations, ensuring functionality and structural integrity. Thermal shock tests its resilience against sudden temperature changes, while vibration testing assesses its robustness under mechanical stress. These processes help identify weak points and improve your design before mass production.

Partnering with experienced automotive PCB suppliers can simplify compliance. They understand the complexities of these standards and can guide you through the process. Their expertise ensures your PCBs meet all necessary requirements, saving you time and resources. By working with trusted suppliers, you can focus on innovation while maintaining compliance.

Meeting industry standards not only enhances the reliability of your PCBs but also strengthens your reputation in the automotive PCB market. Compliance demonstrates your dedication to quality and safety, making your products more appealing to customers and partners.

Tip: Regularly review your compliance documentation and testing processes to stay updated with evolving standards. This proactive approach ensures your PCBs remain competitive and reliable.

Choosing the right materials for your automotive PCB is essential for ensuring durability, performance, and compliance in challenging environments. Materials like FR-4, polyimide, and metal-core PCBs offer unique benefits tailored to different automotive applications. By carefully evaluating your needs and adhering to industry standards, you can design PCBs that deliver reliable performance and stand out in the competitive automotive PCB market. Take the time to make informed decisions, and you’ll create products that exceed expectations.

FAQ

What is the most cost-effective material for automotive PCBs?

FR-4 is your best option for cost-effectiveness. It offers a balance of affordability and performance, making it ideal for standard automotive applications. Its mechanical strength and electrical insulation ensure reliability without breaking your budget.

Tip: Use FR-4 for infotainment systems or basic control modules to save costs without sacrificing quality.

How do I choose the right material for high-temperature environments?

Choose polyimide or ceramic substrates for extreme heat. Polyimide excels in under-the-hood applications, while ceramic substrates handle even higher temperatures. Both materials ensure durability and consistent performance in demanding conditions.

Note: Always match the material to your specific application for optimal results.

Why is thermal conductivity important in automotive PCBs?

Thermal conductivity prevents overheating by dissipating heat efficiently. This protects components and extends the lifespan of your PCB. Materials like metal-core PCBs or aluminum cores are excellent for managing heat in power-intensive systems.

Emoji Insight: 🌡️ High thermal conductivity = Cooler, longer-lasting PCBs!

Are flexible PCBs suitable for automotive applications?

Yes, flexible PCBs are perfect for tight spaces and dynamic designs. They adapt to complex geometries and withstand vibrations, making them ideal for modern automotive systems like sensors and control units.

Pro Tip: Use flexible PCBs to innovate and optimize space in your designs.

How can I ensure my automotive PCBs meet industry standards?

Partner with manufacturers who comply with ISO/TS 16949, IPC-6012DA, and AEC-Q100 standards. These certifications guarantee quality, safety, and reliability. Testing your PCBs for thermal cycling, vibration, and corrosion resistance also ensures compliance.

Reminder: Compliance boosts your product’s credibility and market appeal.