Automotive PCB technology is revolutionizing vehicles, making them smarter, safer, and more efficient than ever before. These advanced circuit boards form the backbone of cutting-edge systems like LiDAR and self-driving functionalities. By integrating sensors and efficiently managing data, automotive PCBs enable seamless real-time communication between essential vehicle components. The growing shift toward electric and autonomous vehicles has significantly increased the demand for high-performance automotive PCBs. These vehicles depend on precise circuit boards to power batteries, process sensor data, and support advanced features such as ADAS. The automotive PCB market is experiencing remarkable growth, projected to rise from USD 9.5 billion in 2023 to USD 15.6 billion by 2032, with a CAGR of 5.8%. This progression highlights the critical importance of automotive PCBs in shaping the future of modern vehicle technology.

Key Takeaways

- Car PCBs are important for safety and working well in modern cars. They help run systems like airbags and anti-lock brakes.

- These boards make cool features like LiDAR and V2X work, which improve how cars perform and keep people safe.

- More people want better car PCBs because of electric and self-driving cars.

- Flexible PCBs and rigid-flex PCBs fit small spaces. They let many sensors and systems work together in tight areas.

- Buying cars with advanced PCBs makes them last longer and work better. This helps make travel safer and more efficient.

What Are Automotive PCBs?

Definition and Purpose

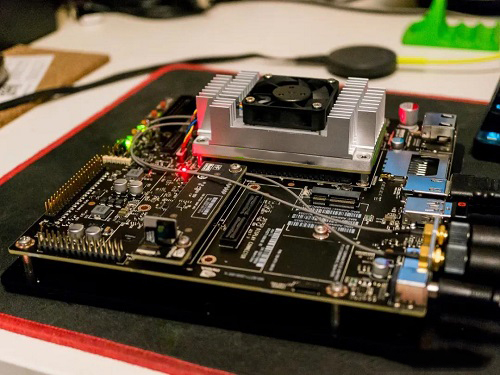

What is an automotive PCB?

An automotive PCB, or printed circuit board, is a specialized electronic platform designed to support and connect various components in modern vehicles. These PCBs serve as the foundation for electronic systems, enabling the integration of sensors, processors, and other critical elements. They are essential for operating systems like engine control units, infotainment systems, and safety features such as airbags and anti-lock brakes. By facilitating compact and efficient designs, automotive PCBs enhance the functionality and reliability of vehicles.

Why are automotive PCBs essential in vehicles?

Automotive PCBs play a pivotal role in the automotive industry by ensuring the seamless operation of electronic systems. They manage complex circuits, enabling advanced features like digital displays, climate control, and power steering. With the increasing electrification and connectivity of vehicles, PCBs have become indispensable for supporting safety, performance, and innovation. Their ability to withstand harsh conditions, such as extreme temperatures and vibrations, further underscores their importance in modern vehicles.

Types of Automotive PCBs

Rigid PCBs

Rigid PCBs are the most common type used in vehicles. They are made from solid materials that do not bend, providing a stable platform for mounting components. These PCBs are ideal for systems requiring durability, such as engine control units and transmission systems.

Flexible PCBs

Flexible PCBs are designed to bend and conform to different shapes, making them suitable for compact spaces. They are often used in applications like lighting systems and infotainment displays, where flexibility and lightweight designs are crucial.

Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of both rigid and flexible designs. They offer durability while allowing flexibility in specific areas, making them ideal for complex systems that require both stability and adaptability, such as advanced driver-assistance systems (ADAS).

General Role in Vehicles

Supporting electronic systems

Automotive PCBs are the backbone of electronic systems in vehicles. They connect and control components like sensors, processors, and actuators, ensuring smooth operation. For example, they manage the intricate circuits in anti-lock brake systems and airbag controls, enhancing safety and performance.

Ensuring reliability in harsh environments

Automotive PCBs are engineered to withstand extreme conditions, including high temperatures, vibrations, and electromagnetic interference. Compliance with ISO 26262 safety standards ensures that these PCBs meet rigorous reliability requirements, reducing the risk of failures in critical systems.

Role of Automotive PCBs in LiDAR Systems

Enabling Signal Processing

Managing high-speed data processing

LiDAR systems rely on rapid data processing to interpret their surroundings accurately. Automotive PCBs play a critical role in managing this high-speed data flow. They process vast amounts of information from LiDAR sensors, ensuring the system can identify objects and obstacles in real time. By optimizing signal pathways, these PCBs reduce delays and enhance the overall performance of LiDAR systems.

Supporting real-time object detection

Real-time object detection is essential for the safety and functionality of autonomous vehicles. Automotive PCBs enable this by integrating advanced processors and memory modules. These components work together to analyze data from LiDAR sensors instantly. This capability allows vehicles to detect pedestrians, other vehicles, and road hazards with precision, ensuring a safer driving experience.

Power Management

Ensuring efficient energy use

Efficient energy use is vital for LiDAR systems, especially in electric and hybrid vehicles. Automotive PCBs regulate power consumption by distributing energy only where it is needed. This reduces waste and ensures the system operates efficiently without draining the vehicle’s battery.

Handling power distribution for LiDAR components

LiDAR systems consist of multiple components, including lasers, sensors, and processors. Automotive PCBs manage the power distribution among these components, ensuring each receives the correct voltage and current. This precise control prevents overheating and extends the lifespan of the system.

Data Transmission

Facilitating communication between sensors and processors

Automotive PCBs facilitate seamless communication between LiDAR sensors and processors. They act as a bridge, transmitting data quickly and accurately. This ensures the system can process information without delays, which is crucial for real-time decision-making.

Ensuring low-latency data flow

Low-latency data flow is critical for LiDAR systems to function effectively. A recent study measured the round-trip time (RTT) for LiDAR data transmission. The results showed an average RTT of 45.6 milliseconds from LiDAR to the mobile edge computing (MEC) system and 47.5 milliseconds from MEC to the subscriber. These figures highlight the reliability of automotive PCBs in reducing latency and ensuring smooth data flow.

| Measurement Type | Minimum (ms) | Maximum (ms) | Average (ms) |

|---|---|---|---|

| RTT (LiDAR to MEC) | 14 | 241 | 45.6 |

| RTT (MEC to Subscriber) | 12 | 111 | 47.5 |

| PCD File Delay (LiDAR to MEC) | 78.3 | 2980 | 245.9 |

Role of Automotive PCBs in Autonomous Systems

Sensor Integration

Connecting cameras, radars, and other sensors

Automotive PCBs serve as the central hub for connecting cameras, radars, and other sensors in autonomous vehicles. These components work together to provide a comprehensive understanding of the vehicle’s surroundings. Multi-layer PCBs are particularly effective in managing the intricate circuitry required for these connections. They ensure seamless integration of sensors, enabling advanced systems like driverless car systems to function reliably. The growing demand for self-driving capabilities has driven the development of high-performance PCBs that can handle the complexity of modern sensor networks.

- Automotive PCBs must endure harsh conditions, such as heat, dust, and moisture, to maintain reliable sensor connections.

- Flexible PCBs allow compact assembly, which is essential for integrating multiple sensors in limited spaces.

- High-density interconnections provided by PCBs enhance the accuracy of detection systems.

Enabling seamless data collection

The ability to collect and process data from multiple sensors is critical for fully autonomous vehicles. Automotive PCBs facilitate this by supporting real-time data fusion. They ensure that information from cameras, radars, and LiDAR systems is transmitted without delays. This capability allows autonomous systems to make accurate decisions based on a complete view of the environment.

- Flexible PCBs provide reliable interconnect solutions, even under dynamic mechanical loads.

- Advanced PCB designs manage intricate circuits, ensuring efficient data collection and processing.

AI and Processing Capabilities

Supporting onboard AI chips and processors

Automotive PCBs play a vital role in supporting the AI chips and processors that power self-driving innovation. These processors analyze vast amounts of data from sensors to make real-time decisions. Multi-layer PCBs are essential for managing the high-performance requirements of these systems. They provide the necessary electrical connections and thermal management to ensure optimal processor performance.

Managing complex algorithms for decision-making

The decision-making algorithms in autonomous vehicles rely on the seamless operation of electronic systems. Automotive PCBs manage these algorithms by ensuring efficient communication between processors and memory modules. This coordination enables the vehicle to interpret sensor data and execute actions with precision.

- PCBs are integral to Advanced Driver Assistance Systems (ADAS), which depend on advanced sensors and circuits.

- Flexible PCBs support the integration of complex control systems, enhancing decision-making capabilities.

Communication Between Vehicle Systems

Enabling Vehicle-to-Everything (V2X) communication

Vehicle-to-Everything (V2X) communication is a cornerstone of self-driving capabilities. Automotive PCBs enable this by facilitating high-speed data transmission between the vehicle and external systems. This communication allows the vehicle to interact with traffic signals, other vehicles, and infrastructure, improving safety and efficiency.

- Automotive PCBs improve signal transmission and reduce latency, ensuring reliable V2X communication.

- Multi-layer PCBs support the miniaturization of components, which is crucial for integrating V2X systems.

Supporting real-time system coordination

Real-time coordination between vehicle systems is essential for autonomous driving. Automotive PCBs ensure this by providing a robust platform for communication between sensors, processors, and actuators. This coordination allows the vehicle to respond quickly to changes in its environment.

| Evidence | Description |

|---|---|

| Integration of electronics | Smart vehicle solutions accelerate the use of advanced electronics in vehicles. |

| Regulatory requirements | Safety and emissions standards drive the need for reliable electronic systems. |

| PCB market growth | The shift towards smarter transportation boosts the demand for automotive PCBs. |

Benefits of Advanced Automotive PCBs

Improved Safety

Enhancing reliability of critical systems

Advanced automotive PCBs form the backbone of critical safety systems in modern vehicles. They ensure the reliable operation of airbags, anti-lock braking systems (ABS), and advanced driver assistance systems. For instance, PCBs process sensor data during collisions to manage airbag deployment, enhancing passenger safety. In ABS, they improve braking responsiveness and vehicle control, reducing the risk of accidents. Designed to endure harsh conditions, these PCBs minimize electrical failures, ensuring optimal performance even in extreme environments.

- Airbags rely on PCBs for precise deployment during emergencies.

- ABS uses PCBs to enhance braking efficiency and stability.

- Advanced driver assistance systems depend on PCBs for accurate alerts and safety features.

Supporting advanced driver-assistance systems (ADAS)

PCBs play a pivotal role in the functionality of advanced driver-assistance systems. These systems, which include lane-keeping assistance and automatic emergency braking, rely on sophisticated PCBs to process data from sensors and cameras. By enabling real-time decision-making, PCBs help prevent collisions and improve overall driving safety. Their ability to handle complex algorithms ensures that ADAS operates seamlessly, providing you with a safer driving experience.

Increased Efficiency

Reducing energy consumption

Modern PCBs contribute significantly to reducing energy consumption in vehicles. They optimize the performance of electronic systems, ensuring minimal power wastage. This efficiency is particularly crucial in electric and hybrid vehicles, where battery management systems depend on PCBs to regulate energy use. By improving fuel efficiency and lowering power consumption, these PCBs support the automotive industry’s shift toward sustainable transportation.

- Enhance fuel efficiency by optimizing energy use.

- Reduce excessive power consumption in electronic systems.

- Support battery management systems in electric and hybrid vehicles.

Optimizing system performance

PCBs enhance the performance of various vehicle systems by ensuring efficient communication between components. They manage intricate circuits in infotainment systems, navigation tools, and lighting features, providing a seamless user experience. Their advanced designs also simplify the operation of auto parts, increasing comfort and adhering to safety regulations. This optimization ensures that fully autonomous vehicles can operate reliably and efficiently.

Enhanced Reliability

Withstanding extreme temperatures and vibrations

Automotive PCBs are engineered to endure the harsh conditions vehicles face daily. Rigorous testing, such as thermal cycling and vibration assessments, ensures their durability. These tests simulate extreme temperature fluctuations and mechanical vibrations to identify potential weaknesses. As a result, PCBs maintain their performance and reliability, even in challenging environments.

| Testing Type | Purpose |

|---|---|

| Thermal Cycling | Simulates extreme thermal conditions to assess PCB’s endurance against temperature fluctuations. |

| Thermal Shock | Evaluates PCB’s response to sudden temperature changes to ensure it can withstand abrupt variations. |

| Vibration Testing | Assesses resilience against mechanical vibrations to identify potential design weaknesses. |

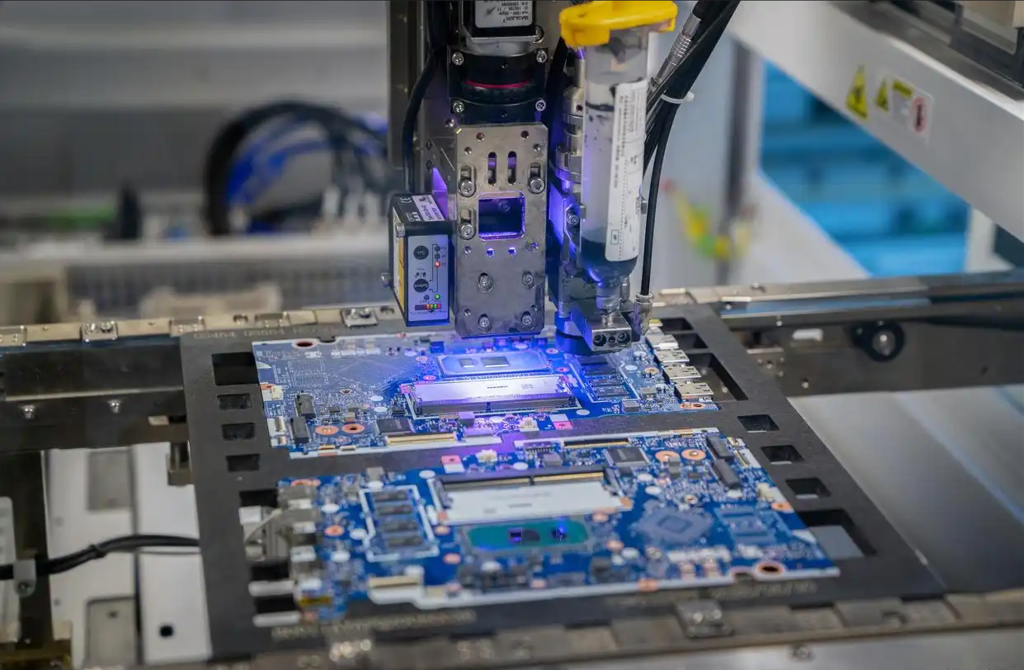

Ensuring long-term durability

The long-term durability of PCBs is crucial for maintaining the reliability of vehicle systems. High-quality materials and advanced manufacturing processes ensure that PCBs can withstand wear and tear over time. This durability is essential for critical systems like lighting, infotainment, and safety features, which must function flawlessly throughout the vehicle’s lifespan. By choosing vehicles equipped with advanced PCBs, you benefit from systems that remain dependable for years.

Future Trends in Automotive PCBs

Miniaturization and High-Density PCBs

Enabling more compact and efficient designs

The trend toward miniaturization in automotive PCBs is reshaping vehicle electronics. You can now find multi-layer PCBs that pack more circuits into smaller spaces, enabling compact designs without compromising functionality. This innovation is crucial for advanced systems like ADAS and infotainment, where space is limited but performance demands are high. The increasing complexity of automotive electronics has driven the adoption of high-density interconnect (HDI) technology, which enhances circuit density and supports intricate designs. These advancements allow manufacturers to create smarter vehicles with streamlined electronic systems.

- Multi-layer PCBs are essential for compact and efficient designs.

- HDI technology supports the growing sophistication of automotive electronics.

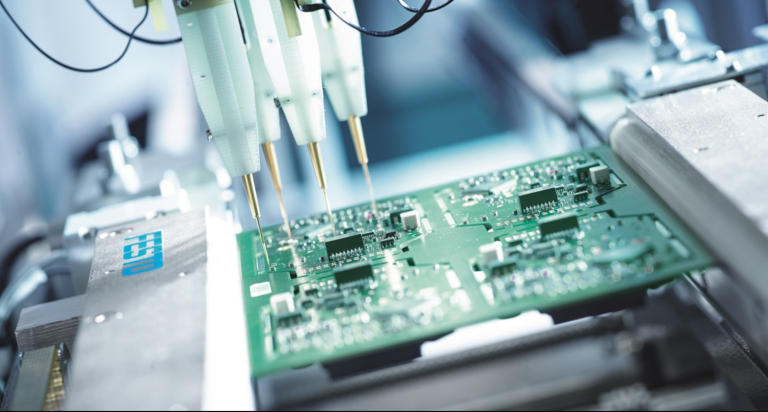

Supporting the integration of more features in smaller spaces

Modern vehicles require PCBs that can handle multiple functions within limited spaces. Flexible PCBs have become popular for their ability to conform to tight spaces while maintaining durability. This flexibility supports the integration of advanced features like 5G connectivity and real-time data processing. As vehicles become more connected, the demand for high-density PCBs will continue to grow, ensuring seamless operation of complex systems.

Use of Advanced Materials

Improving heat resistance and durability

Advanced materials are transforming the performance of automotive PCBs. High-quality substrates and coatings improve heat resistance, ensuring that PCBs can withstand extreme temperatures. This durability is vital for critical systems like battery management systems, which operate under demanding conditions. By using materials that resist wear and tear, manufacturers can enhance the reliability and lifespan of vehicle electronics.

| Evidence Type | Description |

|---|---|

| Multi-layer PCBs | Essential for high performance and reliability in automotive applications. |

| HDI technology | Increases circuit density, crucial for modern vehicle electronics. |

| Flexible PCBs | Allow for intricate and compact designs, enhancing overall vehicle performance. |

Supporting higher power and data demands

The shift toward electric and hybrid vehicles has increased the need for PCBs that can handle higher power and data demands. Advanced materials enable PCBs to manage these requirements efficiently, ensuring optimal performance. For instance, robust PCBs are essential for managing power flow in electric powertrains, reducing energy loss and improving efficiency.

Integration with Emerging Technologies

Supporting electric and hybrid vehicles

The rise of electric and hybrid vehicles has created a demand for specialized PCBs. These vehicles rely on PCBs to manage complex electrical systems, including batteries and charging infrastructure. By supporting energy-efficient powertrain systems, PCBs play a critical role in the transition to electric mobility. This shift aligns with global efforts to reduce carbon emissions and promote sustainable transportation.

- Electric vehicles require high-performance PCBs for battery and charging systems.

- The transition to electric mobility is accelerating the demand for advanced PCBs.

Enabling advancements in autonomous and connected vehicles

Autonomous and connected vehicles depend on PCBs to integrate sophisticated sensors and data processing systems. These PCBs enable real-time communication between vehicle components, ensuring seamless operation. The integration of 5G technology further enhances connectivity, allowing vehicles to interact with their surroundings more effectively. As the automotive industry moves toward smarter transportation, PCBs will remain at the forefront of innovation.

- 5G connectivity requires advanced PCBs to handle higher frequencies and data volumes.

- Autonomous vehicles rely on PCBs for real-time data processing and communication.

Automotive PCBs form the foundation of smarter vehicles, driving advancements in safety, efficiency, and reliability. These circuit boards power critical systems like engine control units, anti-lock brakes, and advanced driver assistance systems (ADAS). By enabling technologies such as LiDAR, V2X communication, and electric powertrains, PCBs have transformed modern transportation.

- Key Contributions of Automotive PCBs:

- Enhance vehicle safety by reducing electrical malfunctions.

- Support ADAS features like lane-keeping assistance and emergency braking.

- Manage battery systems and electric motors in hybrid and electric vehicles.

| Aspect | Description |

|---|---|

| Safety | PCBs ensure the reliable operation of airbags and braking systems. |

| Performance | High-quality PCBs improve the efficiency of electronic systems. |

| Technological Advancements | They enable innovations like ADAS, infotainment systems, and electric powertrains. |

As the demand for intelligent and connected vehicles grows, PCBs will continue to play a pivotal role in shaping the future of transportation. Their ability to integrate emerging technologies ensures that vehicles become smarter, safer, and more capable with each passing year. 🚗✨

FAQ

What makes automotive PCBs different from regular PCBs?

Automotive PCBs are designed to endure extreme conditions like high temperatures, vibrations, and electromagnetic interference. They comply with strict safety standards, such as ISO 26262, ensuring reliability in critical vehicle systems. Regular PCBs lack these specialized features.

Tip: Always choose vehicles with certified automotive PCBs for enhanced safety and performance.

How do automotive PCBs improve vehicle safety?

Automotive PCBs power critical safety systems like airbags, anti-lock brakes, and ADAS. They process sensor data in real time, enabling quick responses during emergencies. Their durability ensures consistent performance under harsh conditions, reducing the risk of system failures.

Can automotive PCBs support electric vehicles?

Yes, automotive PCBs are essential for electric vehicles. They manage battery systems, regulate power distribution, and optimize energy efficiency. Advanced PCBs also support charging infrastructure and ensure the smooth operation of electric powertrains.

Why are flexible PCBs important in modern vehicles?

Flexible PCBs fit into compact spaces and adapt to complex designs. They connect multiple sensors and systems seamlessly, making them ideal for infotainment displays, lighting, and ADAS. Their lightweight and durable nature enhances overall vehicle efficiency.

Note: Flexible PCBs are crucial for integrating advanced features in limited spaces.

What trends are shaping the future of automotive PCBs?

Miniaturization, high-density designs, and advanced materials are driving innovation. These trends enable compact, efficient PCBs that support emerging technologies like 5G, autonomous systems, and electric vehicles. The focus on sustainability also promotes energy-efficient PCB designs.

Emoji Insight: 🌍 Sustainable PCBs are paving the way for greener transportation.