PCB one-stop service simplifies the complexities of PCB fabrication and assembly by consolidating every step under one provider. This approach eliminates inefficiencies caused by vendor transitions, reducing lead times and hidden costs. With complete PCB solutions, you gain faster delivery, minimized errors, and streamlined processes, ensuring both time and cost savings for your projects.

Key Takeaways

- One-stop PCB services make production easier by combining design, making, and assembly with one company. This saves time and avoids mistakes.

- These services shorten waiting times, helping you launch products faster and meet deadlines.

- Using one provider reduces shipping costs and allows buying in bulk for discounts. This helps save a lot on production costs.

Understanding PCB One-Stop Service

What Is a PCB One-Stop Service?

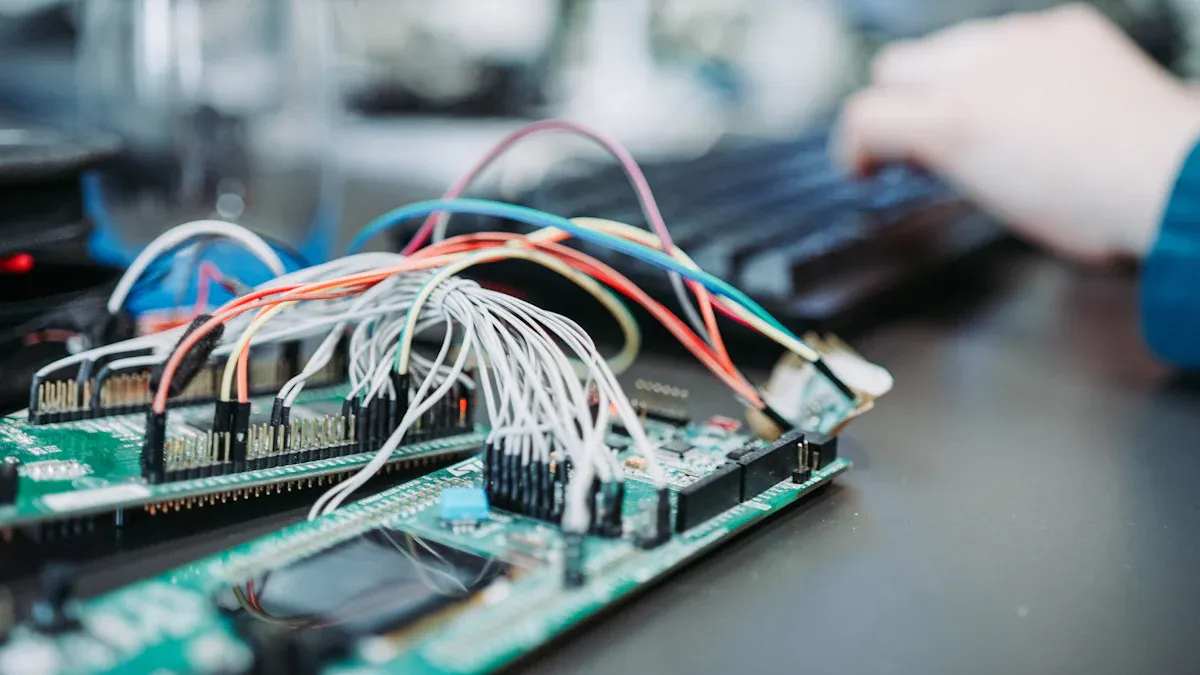

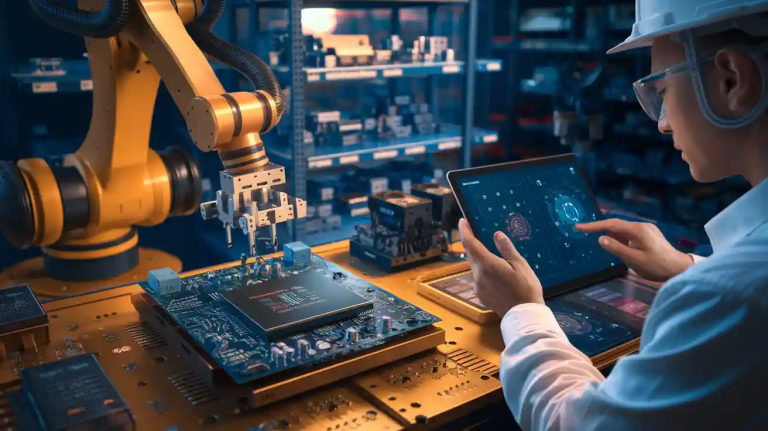

A PCB one-stop service integrates all stages of printed circuit board production under a single provider. This approach covers everything from design and fabrication to assembly and testing. By consolidating these processes, you gain a streamlined solution that eliminates the need to coordinate with multiple vendors. This not only enhances efficiency but also ensures consistent quality throughout the production cycle.

One-stop PCB assembly services have become the preferred choice for manufacturers due to their ability to simplify complex workflows. They offer comprehensive support, addressing every aspect of PCB production. Whether you need small-scale prototypes or high-volume manufacturing, these services adapt to your unique requirements. This flexibility, combined with guaranteed quality, makes one-stop PCBA manufacturing an essential tool for modern electronics production.

Core Components of One-Stop PCB Services

One-stop PCB services consist of several key components that ensure a seamless production process. These include:

- Component Sourcing: Efficient procurement of all necessary parts.

- PCB Fabrication: Precision manufacturing of the circuit boards.

- Assembly: Integration of components onto the PCB with accuracy.

- Quality Control: Rigorous testing to maintain high standards.

- Testing: Final checks to ensure functionality and reliability.

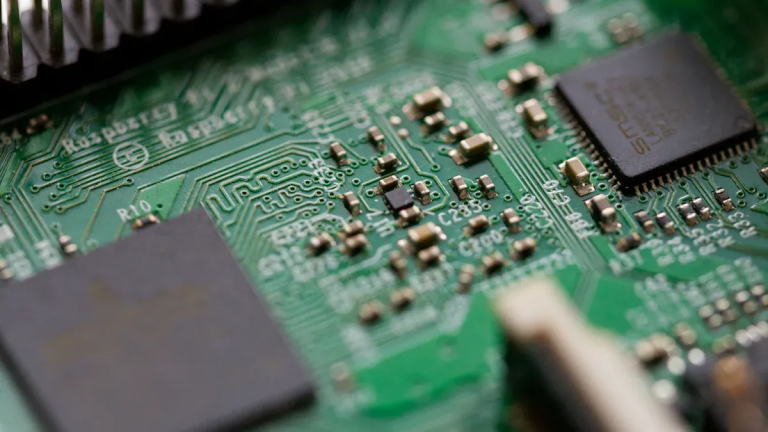

Each component plays a vital role in delivering cost-effectiveness and shorter lead times. For example, advanced AOI testing ensures that your PCBs meet strict quality benchmarks, while streamlined processes simplify monitoring and auditing.

How One-Stop PCB Services Differ from Traditional Methods

One-stop PCB services differ significantly from traditional methods by offering a unified approach. Traditional processes often involve multiple vendors, leading to higher hidden costs, longer lead times, and inconsistent quality. In contrast, one-stop PCB assembly services provide a single point of accountability, reducing the risk of errors and delays.

For instance, a company using one-stop PCBA manufacturing can complete production in 4-6 weeks, compared to 8-12 weeks with traditional methods. This efficiency stems from simultaneous procurement and fabrication, which eliminates unnecessary transitions. Additionally, you benefit from bespoke order handling, ensuring that your specific needs are met without compromise.

Time-Saving Benefits of One-Stop PCB Services

Streamlined Communication and Coordination

One-stop PCB assembly services simplify communication by providing a single point of contact. This eliminates the need to juggle multiple vendors, reducing the chances of miscommunication. When all teams work together under one provider, information flows seamlessly, ensuring that your project stays on track. For example:

- A unified approach minimizes delays caused by vendor transitions.

- Turnkey PCB manufacturing allows for easier monitoring, enhancing coordination and reducing errors.

Streamlined communication ensures that your project progresses smoothly, saving you valuable time.

Faster Turnaround Times

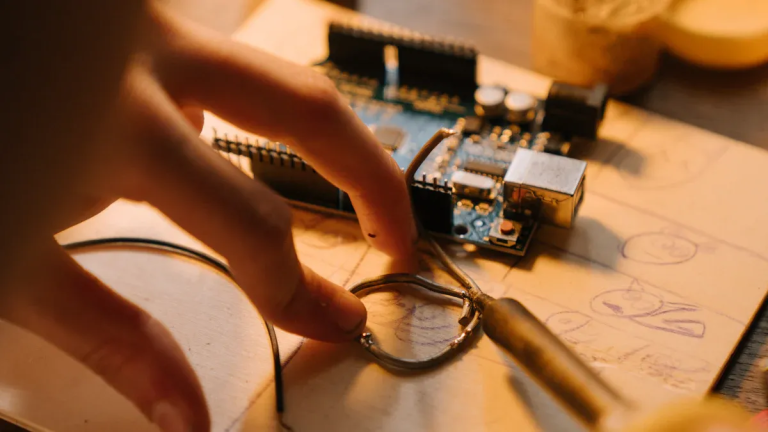

One-stop PCB services significantly reduce lead times compared to traditional methods. By consolidating processes, such as parts procurement and PCB fabrication, downtime is minimized. For instance, once the bare boards are ready, assembly begins immediately. This unified approach ensures faster transitions from design to production.

| Aspect | One-Stop Services | Traditional Methods |

|---|---|---|

| Lead Times | Generally shorter due to coordination | Often longer due to vendor transitions |

| Revisions and Changes | Quicker implementation | Requires coordination with multiple vendors |

With faster turnaround times, you can bring your product to market more quickly.

Simplified Project Management

Managing a PCB project becomes easier with one-stop PCBA manufacturing. A dedicated project manager oversees every stage, ensuring familiarity with your order and timely corrections. Integrated quality control processes also allow for rigorous checks at each step, enhancing efficiency.

Simplified project management reduces misunderstandings and ensures that your project remains on schedule. This comprehensive support guarantees quality and reliability throughout the production cycle.

Reduced Risk of Delays

One-stop PCB assembly services reduce delays by handling design, fabrication, and assembly in one location. This meticulous process ensures that all necessary parts are available before assembly begins. Improved communication further minimizes the risk of errors, keeping your project on time.

For prototypes and small batches, turnkey providers deliver quicker results than traditional methods. This optimized production process ensures that your project avoids unnecessary downtime, saving you both time and resources.

Cost-Saving Benefits of One-Stop PCB Assembly Services

Lower Shipping and Logistics Costs

One-stop PCB assembly services consolidate all production processes under a single provider, significantly reducing shipping and logistics expenses. By eliminating inter-vendor shipping, you avoid additional fees and delays. These services also leverage established relationships with component vendors and shipping partners to optimize costs further.

Tip: Choosing a one-stop solution minimizes hidden costs, as most expenses are included in the quoted price. This streamlined approach ensures long-term savings and cost-effectiveness for your projects.

Bulk Procurement Discounts

One-stop PCB services offer substantial savings through bulk procurement. Providers maintain strong relationships with component vendors, enabling them to secure discounts on materials. For example:

- Reduced Bill of Materials (BOM) costs compared to standard North American vendors.

- Optimized sourcing of hard-to-find components, ensuring availability without inflated prices.

These bulk discounts directly lower production costs, making one-stop PCBA manufacturing a financially sound choice.

Minimized Errors and Rework Costs

Errors during PCB production can lead to costly rework. One-stop PCB assembly services mitigate this risk by integrating design, fabrication, and assembly under one roof. This unified process ensures consistent quality checks at every stage, reducing the likelihood of defects. With guaranteed quality, you save on rework expenses and avoid delays caused by errors.

Improved Resource Allocation

One-stop PCBA services enhance resource allocation by simplifying monitoring and quality control. A single provider manages all processes, ensuring consistent standards and reducing the time spent on audits. Additionally, shorter lead times result from consolidating manufacturing steps, allowing you to allocate resources more efficiently.

Note: A straightforward paper trail from one estimate and invoice simplifies project management, ensuring comprehensive support throughout production.

Real-World Examples of One-Stop PCBA Services

Case Study: Reducing Lead Times for a Small Business

A small electronics startup faced challenges with long lead times when working with multiple vendors. By switching to one-stop PCB assembly services, the company reduced its production timeline from 10-12 weeks to just 4-5 weeks. This significant improvement allowed the business to meet tight deadlines and launch products faster.

The streamlined process eliminated delays caused by vendor transitions. Simultaneous parts procurement and PCB fabrication ensured no downtime, while integrated quality checks minimized errors. As a result, the startup not only saved time but also improved its product quality, with defect rates dropping from 3.5% to less than 0.5%.

Key Takeaway: One-stop PCBA manufacturing accelerates production and enhances quality, making it ideal for businesses with tight schedules.

Example: Cost Savings for High-Volume Manufacturing

High-volume manufacturers often struggle with rising costs due to shipping and procurement inefficiencies. One-stop PCB assembly services address these issues by consolidating processes under one provider. For instance:

- Shipping costs between manufacturers are eliminated, reducing overall expenses.

- A dedicated parts procurement team leverages bulk purchasing to lower the Bill of Materials (BOM) cost.

These efficiencies result in a 23% reduction in overall production costs. Additionally, economies of scale allow manufacturers to increase production capacity by 300% without requiring extra resources. This scalability ensures cost-effectiveness for large-scale operations.

Lessons Learned from Adopting One-Stop PCB Services

The adoption of one-stop PCBA services offers valuable lessons for businesses aiming to optimize their production processes. Key insights include:

| Lesson Learned | Evidence |

|---|---|

| Cost-Effectiveness | Consolidated service reduces expenses related to inter-vendor shipping and optimizes BOM costs. |

| Shorter Lead Times | Simultaneous parts procurement and PCB fabrication lead to no downtime, significantly reducing lead times. |

| Guaranteed Quality | Dedicated project management and rigorous quality checks ensure high standards of quality management. |

| Integrated Efficiency | Consolidation of design, production, procurement, and testing reduces turnaround time. |

| Cost Optimization | Streamlined supply chain eliminates intermediaries, reducing overall manufacturing costs. |

| Quality Assurance | Strict quality control systems ensure high-quality requirements are met, minimizing defective rates. |

These lessons highlight the benefits of one-stop PCB assembly services, from shorter lead times to improved quality assurance. Businesses can achieve long-term savings and operational efficiency by adopting this approach.

One-stop PCB services offer unmatched time and cost savings by consolidating processes under one provider. You gain efficiency, flexibility, and superior quality control, ensuring seamless project execution.

Take Action: Explore one-stop PCB services today to streamline your production, reduce costs, and bring your products to market faster.

FAQ

What industries benefit the most from one-stop PCB services?

One-stop PCB services benefit industries like consumer electronics, automotive, aerospace, and medical devices. These sectors require high-quality, efficient, and cost-effective PCB production solutions.

How do one-stop PCB services ensure quality control?

Providers implement rigorous testing methods, including Automated Optical Inspection (AOI) and functional testing. These processes ensure your PCBs meet strict quality standards before delivery.

Can one-stop PCB services handle custom requirements?

Yes, one-stop PCB providers offer tailored solutions. They adapt to your specific needs, whether for prototypes, small batches, or high-volume production, ensuring flexibility and precision.