Efficient PCB manufacturing relies heavily on your choice of assembly technology. PCB SMT (Surface Mount Technology) streamlines production by enabling high-density assemblies, which can lower costs by 30% to 50%. Through-Hole Technology (THT), on the other hand, ensures robust mechanical bonds, making it ideal for applications under high stress. Understanding these impacts allows you to align your project requirements with the most suitable approach.

Key Takeaways

- SMT improves PCB efficiency by enabling dense assemblies, cutting costs by 30% to 50%.

- THT creates strong connections, perfect for tough and reliable uses in stressful conditions.

- Using both SMT and THT together improves performance, mixing small size with strength for tricky tasks.

Overview of PCB Assembly Technology

What is Surface Mount Technology (SMT)?

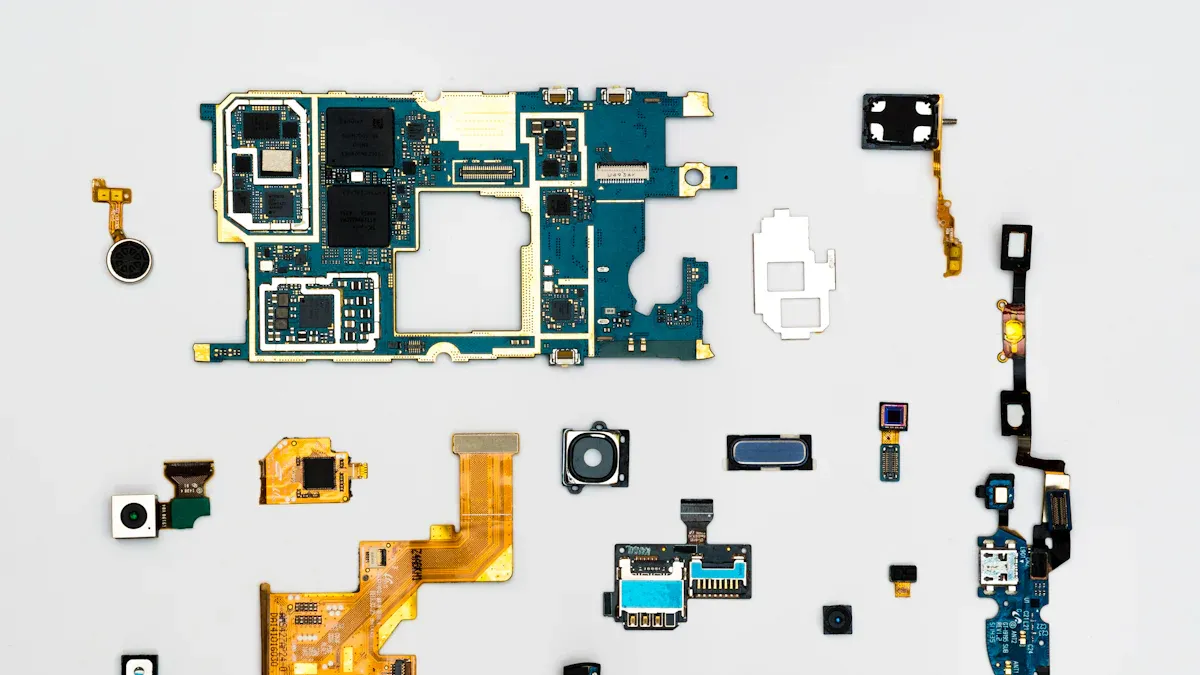

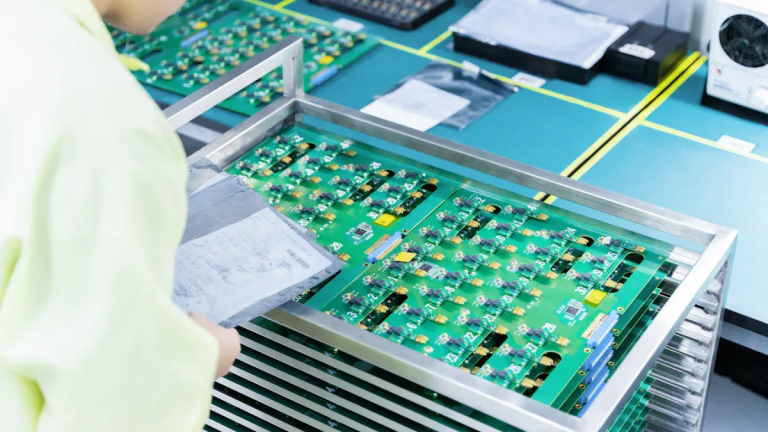

Surface Mount Technology (SMT) revolutionised PCB manufacturing by enabling components to be mounted directly onto the surface of a printed circuit board. This approach eliminates the need for drilling holes, which significantly speeds up production. SMT is particularly suited for compact and lightweight designs, making it the preferred choice for modern electronics like smartphones, wearables, and IoT devices.

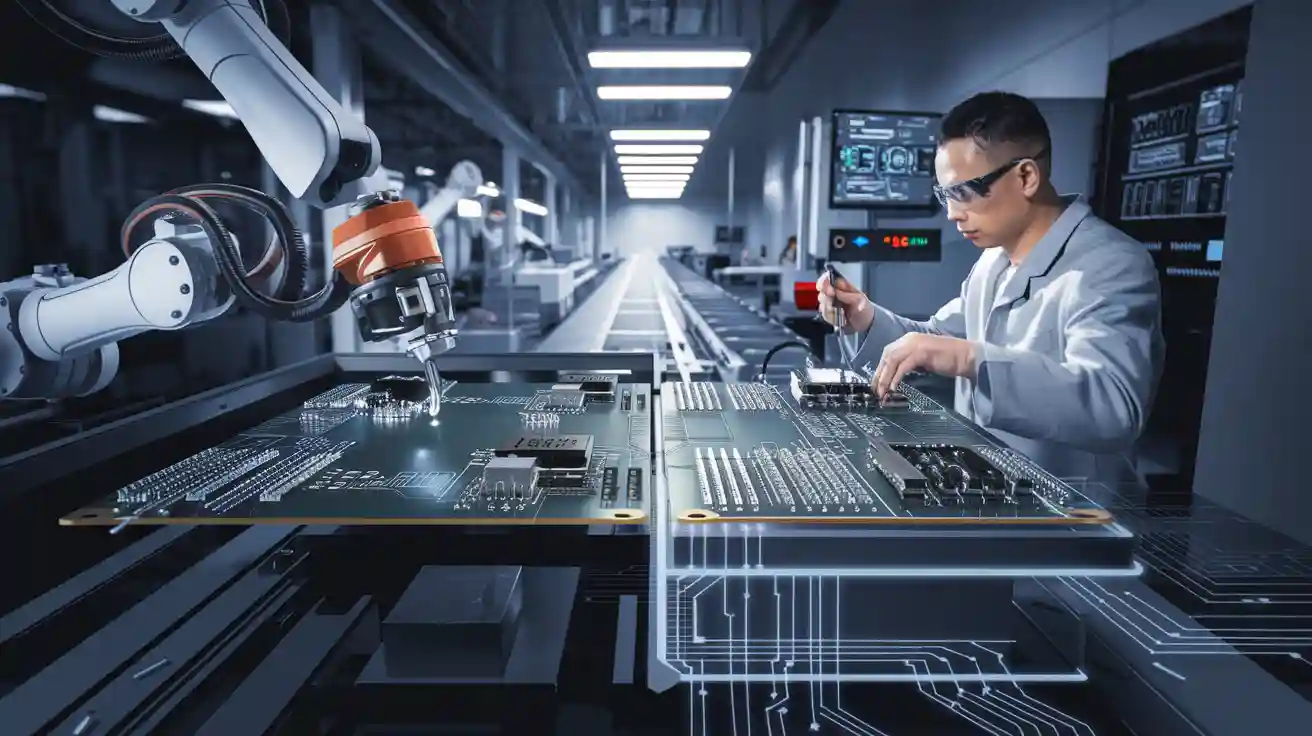

One of the key advantages of SMT is its compatibility with automation. Automated assembly lines can place and solder components with high precision, reducing human error and improving efficiency. Additionally, SMT supports flexible designs, allowing you to combine it with through-hole technology on the same PCB when needed. This versatility makes it a popular choice for high-density assemblies.

Recent advancements in SMT include the use of flexible and rigid-flex PCBs, which cater to the growing demand for innovative applications. The integration of IoT and AI technologies has further enhanced the capabilities of SMT, enabling smarter and more efficient manufacturing processes. With the PCB industry projected to reach $76 billion by 2025, SMT continues to play a pivotal role in meeting the demands of a rapidly evolving market.

What is Through-Hole Technology (THT)?

Through-Hole Technology (THT) involves inserting component leads into pre-drilled holes on a PCB and soldering them to pads on the opposite side. This method creates strong mechanical bonds, making it ideal for applications that require durability and reliability, such as industrial equipment and aerospace systems.

THT is particularly valued for its ability to handle high-stress environments. Components mounted using this method are less likely to detach under physical or thermal stress, ensuring long-term performance. While THT is less compatible with automation compared to SMT, it remains indispensable for specific use cases where robustness is a priority.

In the context of quality assurance, THT benefits from statistical methods like coupon-to-board correlation, which helps manufacturers maintain high standards. Although it may not match the speed and efficiency of SMT, THT continues to serve as a reliable option for specialised applications.

Efficiency Comparison: SMT vs THT

Advantages of pcb smt

Surface mount technology offers several advantages that significantly enhance the efficiency of pcb assembly. Its compact design allows you to place components closer together, enabling lightweight and space-saving layouts. This feature is particularly beneficial for modern electronics like smartphones and IoT devices. SMT also supports faster production since it eliminates the need for drilled holes, reducing both time and labour requirements.

Automation plays a key role in surface mount assembly. Pick-and-place machines can install SMT components with high precision, minimising errors and improving consistency. The smaller size of SMT parts not only reduces costs but also increases availability, making them a practical choice for high-volume production. Additionally, SMT enables higher component density by allowing components to be mounted on both sides of the PCB, which improves design efficiency.

The table below summarises the key advantages of SMT:

| Advantage | Description |

|---|---|

| Compact Design | SMT allows more components to be placed closer together, leading to lightweight and compact designs. |

| Faster Production | SMT setup is quicker due to the use of solder paste instead of drilled holes, saving time and labour. |

| Higher Component Density | Components can be placed on both sides of the board, increasing connections per component. |

| Improved Alignment | Surface tension of molten solder helps align components with solder pads, correcting minor placement issues. |

| Better Signal Integrity | Shorter signal paths due to compactness enhance signal integrity. |

| Lower Heat Dissipation | SMT components dissipate less heat compared to through-hole components. |

Disadvantages of pcb smt

Despite its many benefits, SMT has some limitations. Components used in surface mount technology are generally smaller and more fragile, which makes them less suitable for applications requiring high mechanical strength. You may find that SMT components are more prone to damage during handling or under physical stress.

Another drawback is the reduced power-handling capability of SMT components. Their smaller size limits their ability to manage high voltage or current levels, making them less ideal for power-intensive applications. Additionally, while SMT supports automation, the initial setup cost for automated equipment can be high, which may not be feasible for small-scale projects.

Advantages of tht

Through-hole technology excels in applications where durability and reliability are critical. THT provides strong mechanical connections by soldering component leads through pre-drilled holes, ensuring components remain securely attached even under physical stress. This makes through-hole assembly ideal for high-stress environments such as aerospace and industrial equipment.

THT components can handle higher voltage and current levels effectively, thanks to their larger size. They also exhibit excellent heat tolerance, making them suitable for demanding applications. For example, military and aerospace systems often rely on THT for its ability to endure extreme environmental conditions.

Here is a summary of THT’s advantages:

| Advantage | Description |

|---|---|

| Physical Solid Connections | THT provides strong mechanical connections that enhance reliability. |

| High Heat Tolerance | THT components can withstand higher temperatures, making them suitable for demanding applications. |

| Excellent Power Handling | THT is capable of managing higher voltage and current levels effectively. |

| Robust Mechanical Connection | Ideal for applications with high mechanical stress or vibration. |

Disadvantages of tht

While THT offers robustness, it has certain drawbacks that can impact manufacturing efficiency. The process of drilling holes for through-hole assembly is time-consuming and labour-intensive, which increases production costs. THT is also less compatible with automation, requiring more manual intervention compared to SMT.

The larger size of THT components limits their use in compact designs. You may find it challenging to achieve high component density with THT, which can restrict its application in modern, space-constrained devices. Additionally, the slower production speed of THT makes it less suitable for high-volume manufacturing.

Applications of SMT and THT

Ideal scenarios for surface mount technology

Surface mount technology (SMT) excels in scenarios where compactness, automation, and high-frequency performance are critical. You can achieve higher component density on a PCB because SMT eliminates the need for drilled holes. This allows smaller surface mount devices (SMDs) to be placed closer together. SMT also supports automation, enabling faster and more consistent assembly, especially in high-volume production environments.

If your project involves high-frequency applications, SMT offers superior performance. Shorter leads and paths reduce signal distortion, ensuring better signal integrity. Additionally, SMT is environmentally friendly. It generates less waste material and uses energy-efficient reflow soldering processes. You can also place components on both sides of the PCB, which increases design complexity and supports miniaturisation.

Tip: SMT is ideal for industries like consumer electronics, where compact designs and high production speeds are essential.

Best use cases for through-hole technology

Through-hole technology (THT) is best suited for applications requiring durability and reliability. Its strong mechanical connections make it ideal for high-stress environments. For example, THT components are commonly used in aerospace systems, where they endure extreme conditions. They also handle higher voltage and current levels effectively, making them suitable for power-intensive applications.

The table below highlights THT’s use cases across various industries:

| Industry | Use Case Description |

|---|---|

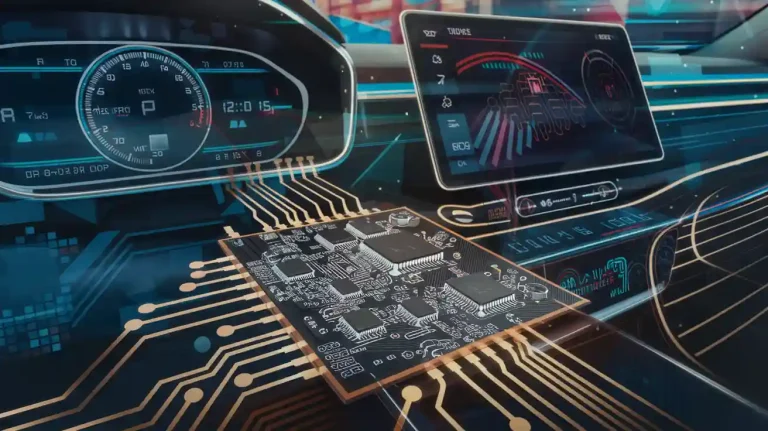

| Automotive | Control modules, engine management systems, and infotainment units requiring durability and reliability. |

| Aerospace | Avionics and navigation systems ensuring reliable operation under extreme conditions. |

| Industrial Machinery | PLCs and motor drives capable of handling high power levels in heavy-duty environments. |

| Medical Devices | Patient monitoring and diagnostic devices ensuring high reliability and safety standards. |

| Telecommunications | Switches and routers capable of handling higher power and providing reliable connections. |

| Consumer Electronics | Audio amplifiers and power supplies preferred for durability and easy repairability. |

| Instrumentation | Oscilloscopes and multimeters providing strong mechanical connections for long-term stability. |

Industry examples of pcb assembly technology

PCB assembly technology has been successfully implemented across various industries. For instance, the ZX series Sequence Controller was developed for dust filter control, leading to the KX system, which improved efficiency and reliability. In environmental control, BPC Electronics collaborated with CCT to innovate PCB assembly for advanced systems.

High Tg PCBs have also demonstrated their effectiveness in industries such as medical devices, automotive, consumer electronics, and telecommunications. These applications highlight the advantages of advanced PCB assembly technology, including enhanced performance and reliability.

Note: Industries like telecommunications and automotive rely heavily on both SMT and THT to meet their diverse requirements.

Combining SMT and THT for Enhanced Efficiency

Benefits of hybrid PCB assembly technology

Combining surface mount technology (SMT) and through-hole technology (THT) in a hybrid PCB assembly offers a balanced approach to manufacturing. This method leverages the strengths of both technologies, enhancing overall efficiency and performance. SMT contributes to compactness and precision, while THT provides mechanical strength and durability. Together, they create a versatile solution for complex designs.

The table below highlights the key benefits of hybrid PCB assembly:

| Benefit | SMT Contribution | THT Contribution |

|---|---|---|

| Cost-effectiveness | Affordable for small parts | Reduces overall manufacturing costs |

| Mechanical strength | N/A | Adds durability for larger components |

| Precision and performance | Enhances signal transmission | N/A |

| Reliability | Reduces failure rates | Ensures durability in harsh environments |

| Optimised performance | Compactness and precision | Mechanical strength for larger components |

By combining these technologies, you can achieve optimised performance, cost savings, and reliability, even in demanding applications.

Examples of hybrid designs

Hybrid PCB designs are tailored to meet specific functional requirements. For instance:

- Customised stackups improve signal integrity, power distribution, and thermal management.

- Selective use of specialised materials addresses heat dissipation and circuit integration challenges.

- Hybrid RF boards combine analogue and digital circuits, operating at frequencies between 2-5 GHz, making them ideal for high-speed applications.

These examples demonstrate how hybrid designs enhance performance and reliability across various industries.

Challenges in combining SMT and THT

While hybrid PCB assembly offers numerous advantages, it also presents challenges. The integration of SMT and THT requires careful planning to ensure compatibility between the two technologies. Differences in soldering processes and assembly techniques can complicate manufacturing. Additionally, hybrid designs may increase production costs due to the need for specialised equipment and expertise.

You must also consider the layout complexity. Combining SMT and THT components on a single board can limit design flexibility and increase the risk of errors during assembly. Addressing these challenges requires a strategic approach and collaboration with experienced manufacturers.

Choosing the Right PCB Assembly Technology

Key factors for selecting SMT or THT

Selecting the right component assembly technology depends on several critical factors. You must evaluate the technical requirements of your project, including the need for high-density assembly, mechanical strength, and superior electrical performance. SMT excels in applications requiring compact designs and efficient automation, while THT offers improved reliability in high-stress environments.

Consider the nature of your components. SMT is ideal for smaller, lightweight parts that benefit from automated processes. THT, on the other hand, suits larger components that demand robust mechanical connections. The table below summarises the key differences between these technologies:

| Technology | Description | Advantages | Disadvantages |

|---|---|---|---|

| SMT | Mounts components directly on the PCB surface. | High density, automated, cost-effective for high volume. | Less suitable for high-stress applications. |

| THT | Inserts components through holes in the PCB. | Strong mechanical connections, suitable for larger components. | More manual, less efficient for high volume. |

You should also assess the environmental conditions your PCB will face. For example, aerospace and automotive applications often require THT due to its ability to withstand extreme temperatures and vibrations. Conversely, consumer electronics benefit from SMT’s compactness and high-speed production capabilities.

Tip: Collaborate with your manufacturer to align your design and prototyping needs with the most suitable printed circuit board assembly technology.

Cost considerations in pcb smt and tht

Cost-effectiveness plays a pivotal role in choosing between SMT and THT. SMT generally offers lower costs due to its compatibility with automated processes. Efficient automation reduces labour expenses and speeds up production, making SMT ideal for high-volume manufacturing. THT, however, involves manual processes, which can increase costs, especially for large-scale projects.

If your design requires components with greater mechanical support, THT may be necessary despite its higher cost. Hybrid assembly, which combines SMT and THT, provides a balanced approach for complex designs. This method optimises cost and performance by leveraging the strengths of both technologies.

Here are some cost-related insights to consider:

- SMT reduces labour costs through automation, making it more economical for high-density assembly.

- THT increases costs due to manual intervention but ensures durability for components under stress.

- Hybrid designs balance cost and functionality, offering a versatile solution for demanding applications.

Note: Minimising THT processes in your PCB assembly can help reduce overall costs while maintaining reliability.

Balancing efficiency with project needs

Balancing efficiency with project-specific requirements involves understanding the trade-offs between SMT and THT. High-density assembly and compact designs favour SMT, while applications requiring improved reliability and mechanical strength lean towards THT. You must prioritise your project’s goals, whether they involve cost savings, durability, or performance.

Case studies illustrate how different industries approach this balance:

- High-Reliability Medical Device: A medical device company prioritised quality and certification, ensuring flawless production despite higher costs.

- Consumer Electronics Startup: A startup focused on rapid prototyping but faced scalability issues during mass production, highlighting the importance of vendor capabilities.

- Cost-Sensitive IoT Project: An IoT company achieved cost savings but encountered communication and quality challenges, emphasising supplier checks.

- Automotive Application: An automotive company balanced cost and quality by selecting a certified manufacturer to meet strict industry standards.

- Complex Multilayer PCB for Telecommunications: A telecommunications company required advanced technical capabilities, demonstrating the need for specialised manufacturers.

Callout: Always align your choice of electronic assembly technology with your project’s long-term goals to ensure optimal performance and cost-effectiveness.

Surface Mount Technology (SMT) and Through-Hole Technology (THT) significantly influence PCB manufacturing efficiency. You should evaluate your project’s specific needs to select the right approach. Hybrid designs offer the best of both worlds, combining compactness with durability.

Tip: Collaborate with experienced manufacturers to optimise your PCB assembly for cost, performance, and reliability.

FAQ

What is the main difference between SMT and THT?

SMT mounts components directly on the PCB surface, while THT inserts components through drilled holes. SMT offers compactness and automation, whereas THT provides durability and mechanical strength.

Tip: Choose SMT for high-density designs and THT for robust, high-stress applications.

Can SMT and THT be used together on the same PCB?

Yes, hybrid PCB assembly combines SMT and THT. This approach leverages SMT’s compactness and THT’s durability, creating versatile designs for complex applications.

How do you decide between SMT and THT for your project?

Evaluate your project’s requirements. Use SMT for compact, high-speed production and THT for durability in harsh environments. Hybrid designs balance both technologies for optimal performance.

Note: Collaborate with your manufacturer to align technology with your project’s goals.