Selecting the right partner for PCB manufacturing is crucial for achieving reliable and high-quality results. A manufacturer’s expertise directly impacts your project’s success. Challenges like inconsistent quality standards, unclear pricing, and communication gaps can derail progress. You must evaluate their experience and technical capabilities to avoid issues such as drill errors, corrosion, or poor soldering. Collaborating with a seasoned manufacturer ensures your designs meet industry standards and withstand environmental factors. By addressing these considerations, you can streamline production and ensure your PCBs perform as intended.

Key Takeaways

- Prioritize manufacturers with ISO and IPC certifications to ensure high-quality standards and reliability in PCB production.

- Evaluate a manufacturer’s ability to handle complex designs and their use of advanced technologies like flexible and rigid-flex PCBs for optimal performance.

- Request detailed quotes and understand pricing structures to avoid hidden fees and ensure transparency in your manufacturing costs.

- Assess the manufacturer’s experience in your specific industry to ensure they can meet unique requirements and deliver tailored solutions.

- Choose a manufacturer committed to sustainable and ethical practices, as this enhances your brand reputation and supports responsible manufacturing.

Quality and Certifications in PCB Manufacturing

Importance of Quality Standards

Look for ISO and IPC certifications.

Certifications play a vital role in ensuring the quality and reliability of PCB manufacturing. When evaluating a manufacturer, you should prioritize certifications like ISO and IPC. These certifications demonstrate a commitment to maintaining high standards and delivering consistent results.

- ISO certifications, such as ISO 9001, provide a framework for quality management systems. They ensure manufacturers meet customer requirements while continuously improving their processes.

- IPC standards establish best practices for PCB design and manufacturing. They ensure that products adhere to strict quality and reliability benchmarks.

Together, these certifications help manufacturers produce high-quality PCBs that meet industry expectations.

| Certification Type | Description |

|---|---|

| ISO 9001 | Covers quality management systems, symbolizing quality and excellence. |

| ISO 13485 | For medical device manufacturers, ensuring safe and effective products. |

| AS9100 | For aerospace applications, ensuring safety and effectiveness. |

| UL Certification | Ensures safety and compliance through rigorous testing. |

| IPC Certification | Ensures quality and reliability with three classes based on application. |

| Military Standards | Ensures the highest quality for military applications, granted by the DLA. |

Ensure compliance with industry-specific standards (e.g., RoHS, UL).

Industry-specific standards like RoHS and UL compliance further enhance the quality of PCB manufacturing. UL certification ensures that PCBs meet stringent safety and reliability requirements. It also includes UL 94, which focuses on the flammability of plastic materials, ensuring fire resistance.

RoHS compliance prohibits the use of hazardous materials in PCBs, promoting ecological responsibility. It ensures manufacturers prioritize environmental safety and helps reduce electronic waste. By choosing a manufacturer with these certifications, you can trust that your PCBs meet both safety and environmental standards.

- RoHS compliance reduces the use of harmful substances in PCBs.

- It promotes sustainable manufacturing practices.

- It minimizes the environmental impact of electronic waste.

Questions to Ask About Quality

What quality control processes do you have in place?

Before selecting a manufacturer, you should inquire about their quality control processes. A reliable manufacturer will have robust systems to monitor and maintain quality throughout production. Ask about their testing methods, such as automated optical inspection (AOI) or X-ray testing, to ensure defect-free PCBs.

Can you provide documentation of certifications and testing?

Request documentation to verify the manufacturer’s certifications and testing procedures. This step ensures transparency and confirms their adherence to industry standards. Reliable manufacturers will readily provide this information, giving you confidence in their capabilities.

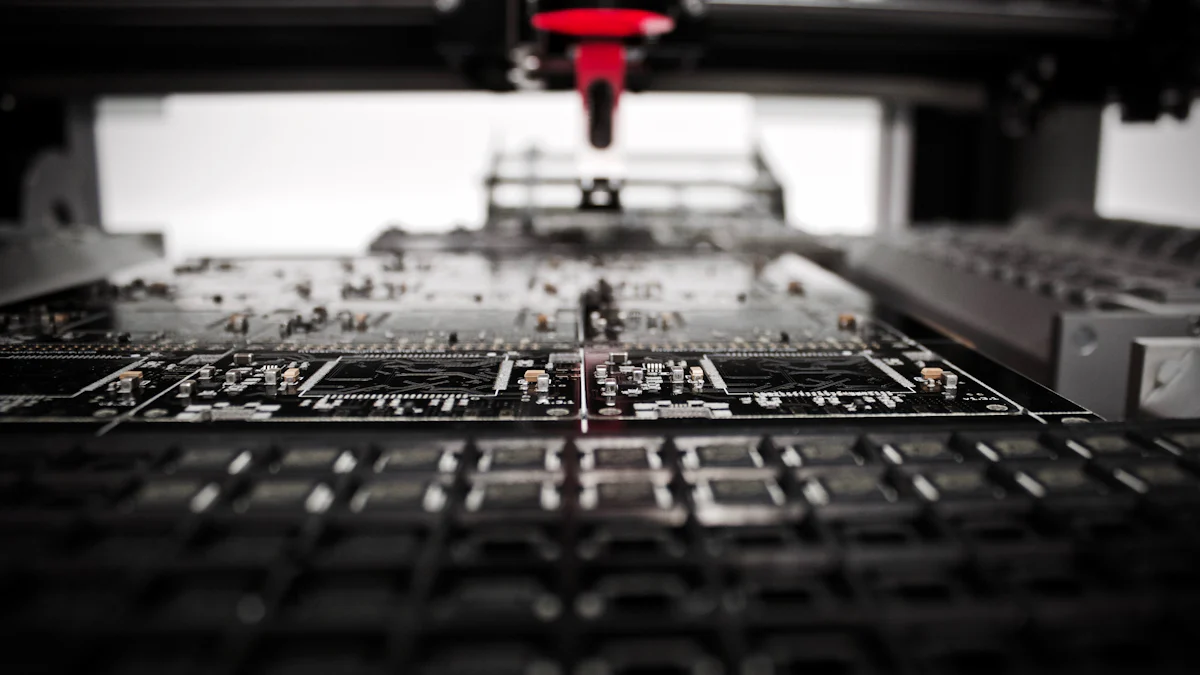

Manufacturing Capabilities of KING FIELD

Assessing Technical Capabilities

Can the manufacturer handle your design complexity (e.g., multilayer, HDI)?

When evaluating a PCB manufacturer, you must ensure they can handle the complexity of your designs. KING FIELD excels in producing multilayer PCBs and High-Density Interconnect (HDI) boards. These advanced technologies allow for compact designs with higher circuit density, making them ideal for modern applications like smartphones and IoT devices. KING FIELD employs cutting-edge equipment, such as multi-layer presses and laser direct imaging (LDI), to achieve precision and reliability in complex designs.

Do they offer advanced technologies like flexible PCBs or rigid-flex?

KING FIELD offers flexible and rigid-flex PCBs, which are essential for space-constrained and dynamic applications. Flexible PCBs provide design freedom and are lightweight, making them suitable for aerospace and medical devices. Rigid-flex PCBs combine the benefits of both rigid and flexible boards, offering reduced packaging size and increased reliability. These technologies enhance product performance while simplifying repair and maintenance processes.

Production Volume and Scalability

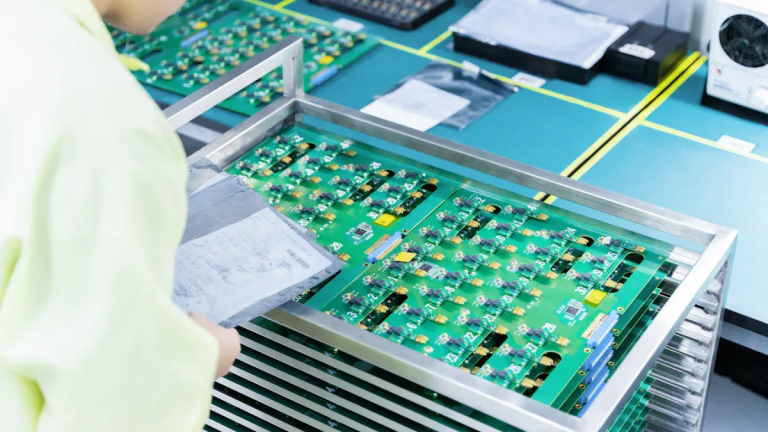

Can they handle both small prototypes and large-scale production?

KING FIELD supports both small-scale prototyping and high-volume production. Their advanced manufacturing processes ensure consistent quality across all production scales. Whether you need a few prototypes for testing or mass production for market launch, KING FIELD adapts to your requirements seamlessly.

What is their maximum production capacity?

With over 20 years of experience, KING FIELD has developed a robust supply chain and scalable infrastructure. This allows them to meet high production demands without compromising quality. Their ability to scale production ensures timely delivery, even for large orders.

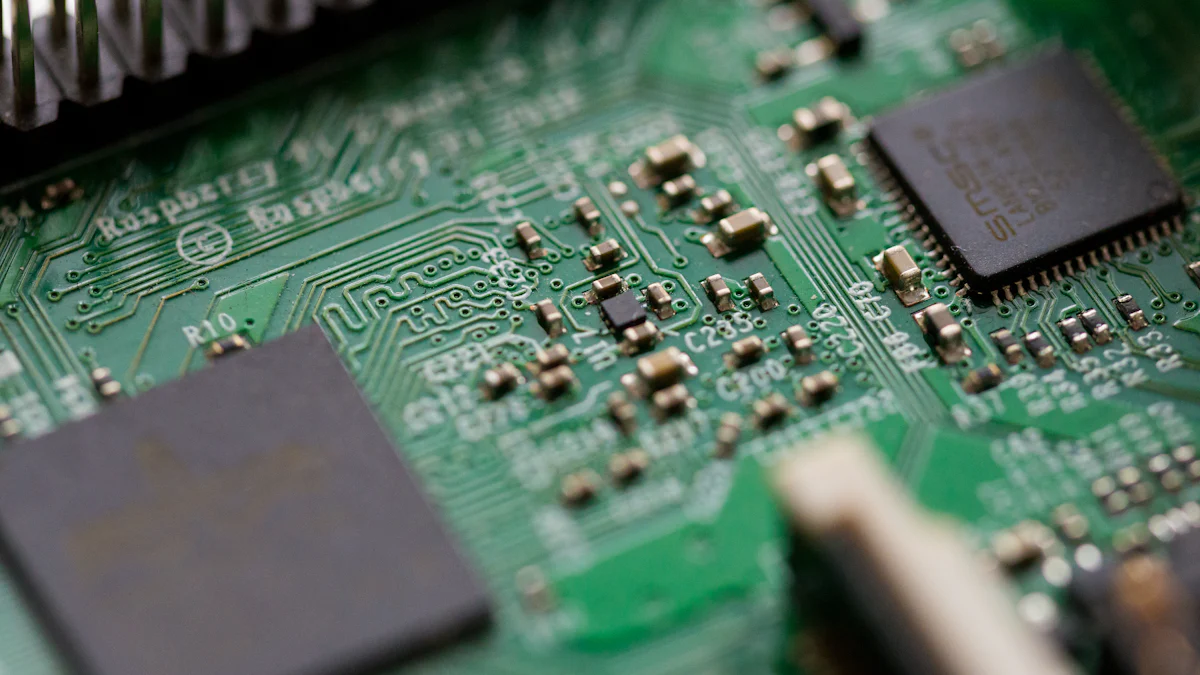

Material and Component Options

Do they source high-quality materials?

KING FIELD prioritizes the use of premium materials, such as high-Tg substrates for high-temperature environments and polyimide for thermal stability. These materials ensure durability and performance in demanding applications like industrial machinery and medical instruments.

Are they open to using customer-specified components?

KING FIELD offers flexibility in sourcing components. They work closely with clients to integrate customer-specified parts, ensuring the final product meets exact specifications. This collaborative approach guarantees satisfaction and optimal performance.

Experience and Reputation in PCB Manufacturing

Evaluating Industry Experience

How long has the manufacturer been in business?

The length of time a manufacturer has been in business speaks volumes about their expertise and reliability. Companies with decades of experience, like KING FIELD, bring a wealth of knowledge to every project. Their refined processes and ability to adapt to challenges ensure consistent quality. Long-established manufacturers have likely encountered a wide range of scenarios, which enhances their operational confidence. This experience helps them avoid setbacks that could delay your PCB assembly or compromise quality.

When choosing a partner, prioritize manufacturers with a proven track record. Their years of experience directly influence the reliability and performance of your printed circuit boards. Working with seasoned professionals ensures your designs meet industry standards and withstand rigorous applications.

Do they have experience in your specific industry or application?

A manufacturer’s familiarity with your industry or application is equally important. Specialized experience allows them to understand unique requirements and deliver tailored solutions. For example, KING FIELD serves diverse industries, including medical, automotive, and consumer electronics. Their expertise in these fields ensures they can meet stringent standards, such as those required for medical devices or automotive safety systems.

By selecting a manufacturer with relevant industry experience, you gain a partner who understands your challenges and can provide innovative solutions. This alignment minimizes risks and ensures your project’s success.

Checking Reviews and References

What do past clients say about their services?

Client feedback offers valuable insights into a manufacturer’s reputation. Positive reviews highlight strengths like quality control, customer service, and on-time delivery. Look for testimonials that emphasize reliability and attention to detail. KING FIELD’s global clientele, spanning countries like the USA and Japan, reflects their commitment to excellence. Their ability to meet diverse client needs underscores their adaptability and professionalism.

Online reviews, forums, and industry-specific platforms can help you gauge customer satisfaction. Consistently high ratings indicate a manufacturer’s dedication to quality and customer satisfaction.

Can they provide references or case studies?

Requesting references or case studies is another effective way to evaluate a manufacturer’s capabilities. Reliable manufacturers, like KING FIELD, often showcase case studies that demonstrate their expertise in handling complex projects. These examples provide a clear picture of their problem-solving skills and ability to deliver results.

References from past clients can also validate a manufacturer’s claims. Speaking directly with previous customers allows you to ask specific questions about their experience. This step ensures you choose a partner who aligns with your expectations and project goals.

Cost and Pricing Transparency with KING FIELD

Understanding Pricing Structures

Are there hidden fees or additional costs?

When evaluating a PCB manufacturer, understanding their pricing structure is essential. Hidden fees or unexpected costs can disrupt your budget and delay your project. KING FIELD ensures transparency by providing clear and upfront pricing. They account for all cost components, including material selection, design complexity, and order quantity. This approach eliminates surprises and helps you plan effectively.

PCB manufacturing costs often depend on several factors:

- Overall Size of PCBs: Larger boards with more layers require more resources, increasing costs.

- Thickness of PCBs: Thicker boards impact material usage and thermal properties, affecting pricing.

- Turnaround Time: Expedited orders may incur additional charges due to prioritization.

- Customizations: Unique features or specifications demand extra time and resources.

- Shipping Costs and Location: Logistics and shipping distances influence final expenses.

By understanding these variables, you can better assess the value offered by KING FIELD.

Do they offer detailed quotes with breakdowns?

A detailed quote provides clarity and builds trust. KING FIELD delivers comprehensive quotes that outline each cost component. These include material specifications, production processes, and testing services. This level of detail allows you to evaluate whether the pricing aligns with your project’s requirements. Transparent quotes also make it easier to compare KING FIELD’s offerings with other manufacturers, ensuring you make an informed decision.

Balancing Cost and Value

Is the pricing competitive for the quality offered?

Balancing cost and quality is critical in PCB manufacturing. Opting for the cheapest option may lead to higher expenses in the long run due to potential failures or rework. KING FIELD strikes the perfect balance by offering competitive pricing without compromising quality. Their use of advanced materials and technologies ensures reliable performance, even for complex designs. For instance, selecting high-quality laminates or sourcing premium components may slightly increase costs but guarantees durability and functionality.

Decisions made during the design phase significantly impact both cost and quality. KING FIELD’s expertise helps you optimize these decisions, ensuring your PCBs meet industry standards while staying within budget.

Are there discounts for bulk orders or long-term partnerships?

Bulk orders and long-term collaborations often result in cost savings. KING FIELD offers attractive discounts for high-volume production, reducing the per-unit cost. This approach benefits businesses looking to scale operations or launch products in competitive markets. Establishing a long-term partnership with KING FIELD can also unlock additional benefits, such as priority support and customized pricing models. These incentives make KING FIELD a cost-effective choice for both small-scale and large-scale projects.

By choosing KING FIELD, you gain a partner committed to delivering value through transparent pricing and exceptional quality.

Production and Lead Times in PCB Manufacturing

Turnaround Time Expectations

What is their standard lead time for prototypes and production runs?

Understanding lead times is critical when selecting a PCB manufacturer. KING FIELD offers competitive turnaround times for both prototypes and production runs. Their efficient processes ensure you receive your PCBs without unnecessary delays. Below is a comparison of standard and expedited lead times in the industry:

| Service | Standard Lead Time | Expedited Lead Time |

|---|---|---|

| PCB Fabrication | 4-5 days | 24-48 hours |

| PCB Assembly | 5-7 days | 3-5 days |

| Full Turnkey | 10-15 days | 5-7 days |

KING FIELD aligns with these industry benchmarks, ensuring timely delivery for your projects. Their streamlined operations and advanced equipment allow them to meet tight deadlines while maintaining quality.

Can they accommodate rush orders if needed?

In fast-paced industries, you may require quick turnarounds to meet market demands. KING FIELD excels in handling rush orders without compromising quality. Their robust infrastructure and skilled workforce enable them to prioritize urgent projects. Whether you need a prototype in 48 hours or a full production run expedited, KING FIELD adapts to your timeline. This flexibility ensures your project stays on track, even under tight schedules.

On-Time Delivery Track Record

What is their on-time delivery rate?

A manufacturer’s on-time delivery rate reflects their reliability. KING FIELD boasts a strong track record of meeting deadlines, ensuring your PCBs arrive as promised. Their commitment to punctuality stems from efficient supply chain management and proactive planning. By partnering with KING FIELD, you minimize risks of delays that could disrupt your project timeline.

How do they handle delays or unforeseen issues?

Delays in PCB manufacturing can arise from various factors, such as supply chain disruptions or design errors. KING FIELD mitigates these risks through strategic measures:

| Cause/Strategy | Description |

|---|---|

| Supply Chain Disruptions | Maintains relationships with multiple suppliers to ensure consistent material availability. |

| Design Errors and Engineering Changes | Collaborates closely with clients to align designs with manufacturing capabilities, reducing late-stage changes. |

| Equipment Malfunction or Downtime | Implements preventive maintenance schedules to avoid unplanned downtime. |

KING FIELD’s proactive approach ensures minimal impact on your project. Their transparent communication keeps you informed, allowing you to plan effectively even in unforeseen circumstances.

Customer Service and Communication with KING FIELD

Responsiveness and Support

How quickly do they respond to inquiries?

Quick responses are essential when working with a PCB manufacturer. KING FIELD prioritizes fast communication, ensuring you receive answers to your inquiries promptly. Their professional team is trained to address your questions efficiently, minimizing delays in decision-making. Whether you need clarification on design specifications or updates on production timelines, KING FIELD’s responsiveness helps keep your project on track.

Do they offer technical support during the design and production phases?

Technical support plays a critical role in ensuring your PCB designs are manufacturable and meet industry standards. KING FIELD provides expert guidance throughout the design and production phases. Their team collaborates with you to identify potential issues early, reducing the risk of costly revisions. This proactive approach ensures your PCBs are optimized for performance and reliability.

Communication Channels

Are they available via multiple channels (e.g., email, phone, chat)?

Effective communication requires accessibility through various channels. KING FIELD offers multiple ways to connect, including email, phone, and online chat. This flexibility allows you to choose the most convenient method for your needs. Their availability across different platforms ensures you can reach them quickly, regardless of your location or time zone.

Do they provide regular updates on order status?

Keeping you informed about your order’s progress is a priority for KING FIELD. They provide regular updates at every stage of production, from material sourcing to final delivery. This transparency helps you plan your next steps with confidence. By maintaining clear communication, KING FIELD ensures you stay informed and avoid unexpected surprises.

Key Attributes of Excellent Customer Service in PCB Manufacturing

- Experience and expertise in handling diverse projects.

- Strong quality control measures to ensure reliability.

Effective communication to keep you updated on timelines.

Key Attribute Description Effective Communication Keeping customers informed about production and delivery timelines helps prevent delays. Responsiveness and Support Quick responses and technical assistance ensure smooth project execution. Customization Capabilities Offering flexible options tailored to your specific requirements. KING FIELD’s commitment to customer service ensures a seamless experience, making them a trusted partner for your PCB manufacturing needs.

Additional Considerations in PCB Manufacturing

Testing and Quality Assurance

Do they offer in-house testing services (e.g., AOI, X-ray, functional testing)?

In-house testing services are essential for ensuring the reliability and functionality of your PCBs. Manufacturers offering these services can identify and address potential issues early in the production process. KING FIELD provides a comprehensive range of testing methods to guarantee quality, including:

- In-Circuit Test (ICT): Detects up to 98% of faults, ensuring high accuracy.

- Fixtureless In-Circuit Test (FICT): A cost-effective alternative to ICT, eliminating the need for custom fixtures.

- Functional Circuit Test: Verifies that the PCB operates as intended under real-world conditions.

- X-Ray Inspection (AXI): Identifies defects in solder joints and internal traces using advanced imaging technology.

These testing methods help you avoid costly errors and ensure your PCBs meet performance standards.

Tip: In-house testing saves time and reduces costs by identifying issues during prototyping. It also enhances safety by preventing potential hazards like electrical fires.

Can they provide test reports for your records?

Requesting test reports from your manufacturer ensures transparency and accountability. KING FIELD delivers detailed documentation for every testing phase, giving you confidence in the quality of your PCBs. These reports include data on defect detection, performance metrics, and compliance with industry standards. Having access to these records allows you to verify the reliability of your products and maintain a clear audit trail for future reference.

Environmental and Ethical Practices

Are they committed to sustainable manufacturing practices?

Sustainability is a growing concern in PCB manufacturing. You should prioritize manufacturers that adopt eco-friendly practices to minimize environmental impact. KING FIELD demonstrates its commitment to sustainability through:

- Energy-efficient processes: Reducing energy consumption during production.

- Proper waste management: Recycling materials to recover valuable resources and reduce waste.

- Eco-friendly materials: Using alternatives that lower the environmental impact of chemical usage.

- Regulatory compliance: Adhering to environmental regulations to manage hazardous substances responsibly.

These practices not only protect the environment but also align with global efforts to promote sustainable manufacturing.

Do they adhere to ethical labor standards?

Ethical labor practices are crucial when selecting a PCB manufacturer. KING FIELD upholds strict labor standards, ensuring fair wages, safe working conditions, and compliance with international labor laws. By choosing a manufacturer committed to ethical practices, you support a supply chain that values human rights and workplace safety. This commitment reflects positively on your brand and fosters trust among your customers.

Note: Partnering with an environmentally and ethically responsible manufacturer enhances your reputation and contributes to a sustainable future.

Choosing the right PCB manufacturer involves evaluating several critical factors:

- Quality standards and certifications

- Manufacturing capabilities and scalability

- Industry experience and reputation

- Transparent pricing and competitive costs

- Lead times and on-time delivery

- Customer service and communication

KING FIELD stands out with its commitment to quality, advanced thermal management technology, and customizable solutions using premium materials like aluminum and copper. Their rigorous testing ensures durable, high-performance PCBs that reduce maintenance costs. By asking the right questions and avoiding common mistakes, you can secure a reliable partner and achieve long-term benefits like cost savings, efficiency, and superior product quality.

FAQ

1. What is the minimum order quantity (MOQ) for PCB manufacturing?

Most manufacturers, including KING FIELD, offer flexible MOQs. You can order as few as one prototype or scale up to thousands for mass production. This flexibility ensures you can test designs or meet large-scale demands without unnecessary constraints.

2. How do I ensure my PCB design is manufacturable?

Collaborate with your manufacturer during the design phase. KING FIELD provides design-for-manufacturability (DFM) reviews to identify potential issues early. This process ensures your design aligns with production capabilities, reducing errors and delays.

3. What factors affect PCB manufacturing costs?

Costs depend on board size, layer count, material type, and turnaround time. Additional features like custom finishes or advanced technologies (e.g., HDI) also impact pricing. KING FIELD provides detailed quotes to help you understand cost breakdowns.

4. Can I request a sample before full production?

Yes, most manufacturers, including KING FIELD, offer prototype services. Ordering a sample allows you to test functionality and quality before committing to large-scale production. This step minimizes risks and ensures satisfaction.

5. How do I track my PCB order status?

KING FIELD provides regular updates through email or online portals. You can monitor progress at every stage, from material sourcing to final delivery. This transparency ensures you stay informed and prepared for the next steps.

Tip: Always confirm communication channels with your manufacturer to avoid miscommunication during production.