Selecting the right Industrial Control Board is crucial for optimizing performance and ensuring long-term reliability. With the industrial controllers market projected to grow from USD 160,406.62 million in 2024 to USD 255,991.5 million by 2032, the demand for tailored Industrial Control Board solutions continues to rise. Your decision impacts operational efficiency, compliance, and scalability. Whether you’re choosing the right Industrial Control Board for a new system or upgrading existing industrial control panels, understanding your needs is key. This advice will help you navigate the complexities of selection and find a solution that aligns with your goals.

Key Takeaways

- Know what your system needs before picking a control board. Check things like the environment and what the board must do.

- Make sure it meets safety rules like UL 508A. This keeps it safe to use and avoids problems later.

- Pick boards with modular designs for easy upgrades. You can change parts as needed without replacing everything.

- Think about the total cost, not just the price. Look at energy savings and lower repair costs over time.

- Buy from trusted brands with good reviews and helpful support. This gives you reliable products and help when needed.

Understanding Application Needs for Industrial Control Boards

Operational Requirements

Environmental conditions and durability

When selecting an industrial control board, you must evaluate the environmental conditions where it will operate. Factors like temperature extremes, humidity, and exposure to dust or chemicals can impact performance. For instance, industrial control panels used in outdoor or hazardous environments require robust enclosures and components that meet specific safety standards. Referencing certifications like UL 508A or UL 698A ensures the board’s durability and compliance with regional safety regulations.

| Safety Standard | Region | Description |

|---|---|---|

| UL 508A | North America | Standard for industrial control panels |

| UL 698A | North America | Standard for hazardous locations |

| EN 60204-1 | EU | Safety of machinery – Electrical equipment |

| EN 61439-1 | EU | Low-voltage switchgear and controlgear assemblies |

Specific functionalities and performance goals

Your industrial control applications demand precise functionalities. Whether you need advanced automation, real-time monitoring, or integration with programmable logic controllers (PLCs), the board must align with your performance goals. For example, if you require high-speed data processing, ensure the board supports the necessary input/output (I/O) configurations and communication protocols.

Scalability and Future-Proofing

Modular vs. fixed designs

Modular designs offer flexibility and scalability, allowing you to adapt to changing requirements. Unlike fixed designs, modular industrial control panels enable you to add or replace components without overhauling the entire system. This approach minimizes downtime and reduces long-term costs.

Planning for future upgrades

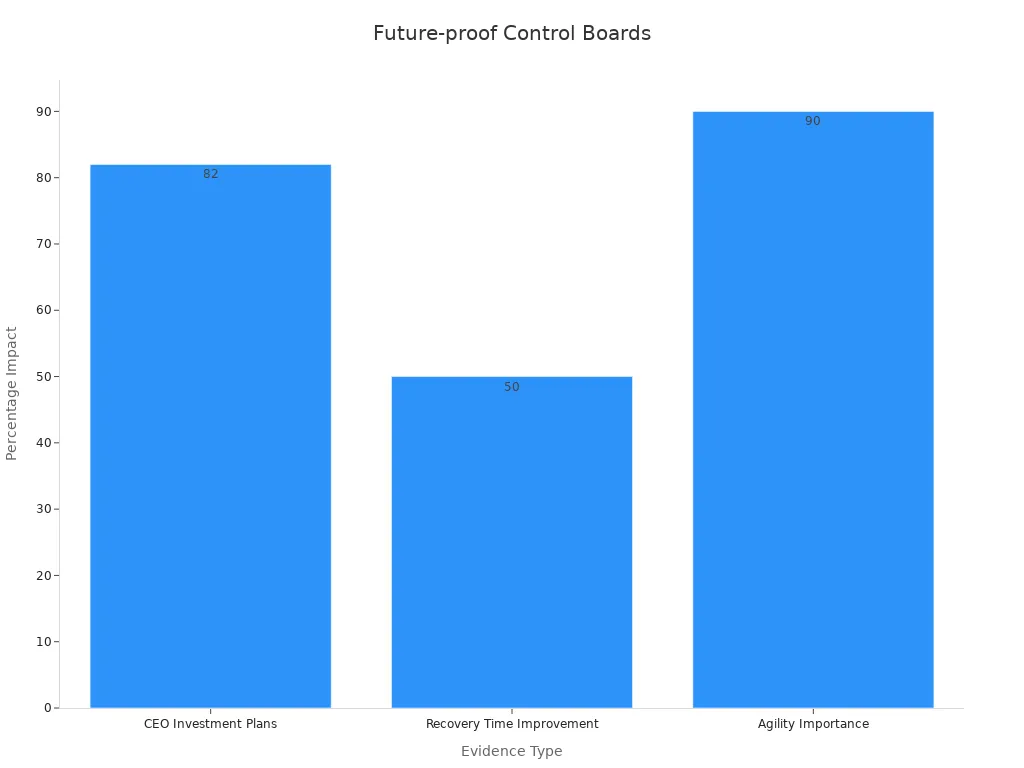

Future-proofing your system involves planning for technological advancements. Research shows that 82% of CEOs in supply-chain-intensive industries plan to increase investment in digital capabilities. Flexible and scalable industrial control boards ensure your system remains relevant as new technologies emerge.

Industry-Specific Customization

Tailored solutions for niche applications

Industrial control boards often require customization to meet the unique demands of niche applications. For example, industries like oil and gas or pharmaceuticals may need specialized boards designed for hazardous locations or cleanroom environments. Tailored solutions ensure optimal performance and compliance with industry-specific criteria.

Integration with specialized equipment

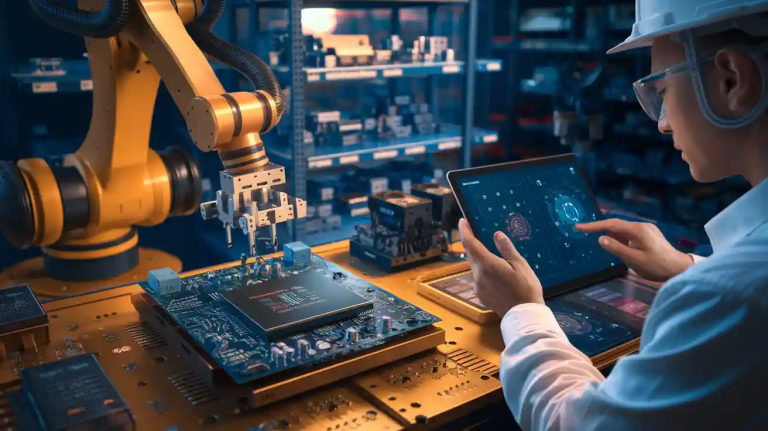

Seamless integration with specialized equipment is critical for efficient operations. Whether you’re working with robotics, conveyor systems, or industrial controllers, the board must support the necessary interfaces and protocols. This ensures smooth communication and enhances overall system efficiency.

Regulatory Compliance in Industrial Control Board Selection

Certifications and Standards

UL 508A and other key certifications

Adhering to certifications like UL 508A is critical when selecting industrial control panels. UL 508A ensures that panels meet stringent safety standards, safeguarding both equipment and personnel. For hazardous environments, UL 698A provides additional guidance, ensuring compliance with safety requirements. These certifications not only enhance operational safety but also align with municipal regulations, reducing liability risks.

| Standard | Description |

|---|---|

| UL 508A | Baseline standard for industrial control panels (ICPs) used in ordinary locations. |

| UL 698A | Supplemental standard for ICPs in hazardous locations, ensuring safety and compliance. |

| EN 60204-1 | European standard for safety of electrical equipment in industrial environments. |

| EN 61439-1 | European standard for low-voltage switchgear and controlgear assemblies. |

| UL 845 | Standard for industrial motor control centers. |

| UL 1773 | Standard for power-operated dispensing devices for flammable liquids. |

| UL 1008 Annex J | Outlines testing standards for transfer switches. |

Compliance with these standards ensures that your industrial control panels operate safely and efficiently. For example, UL 508A control panels are widely recognized for their reliability in ordinary locations, while UL 698A is indispensable for hazardous areas. Following these guidelines minimizes operational risks and ensures adherence to local and international regulations.

Regional and industry-specific compliance

Different regions and industries impose unique compliance requirements. In North America, UL certifications dominate, while European markets prioritize EN standards like EN 60204-1 and EN 61439-1. Industry-specific needs, such as those in oil and gas or pharmaceuticals, may demand additional certifications tailored to hazardous or sterile environments. Understanding these requirements is essential for ensuring your industrial control board meets all necessary safety standards.

Safety and Operational Reliability

Ensuring safe operation in critical environments

Safety is paramount in critical industrial environments. Regular safety audits can identify potential risks and improve operational efficiency. These audits often lead to enhanced training programs, increasing workforce awareness of safety procedures. For example, compliance with ISO 45001 guidelines helps establish a safe and healthy workplace, reducing the likelihood of accidents.

Avoiding penalties for non-compliance

Non-compliance with safety standards can result in severe penalties, including fines and operational shutdowns. Post-accident investigations often reveal violations of safety procedures due to inadequate audits or training. For instance, the Chernobyl disaster underscores the importance of adhering to safety protocols. By following established guidelines and conducting regular audits, you can avoid such penalties and maintain a safe working environment.

Tip: Always consult with experts or refer to industry-specific advice to ensure your programmable logic controller and industrial control panels meet all regulatory requirements.

Evaluating Compatibility and Integration

Hardware Compatibility

Seamless integration with existing systems

Ensuring hardware compatibility is essential when selecting industrial control panels. The control board must integrate seamlessly with your existing systems to avoid operational disruptions. For example, industrial controllers often rely on precise hardware-software coordination, similar to how smartphones depend on operating systems like iOS or Android to manage sensors and cameras. Likewise, robots in manufacturing environments use software to execute precision tasks, highlighting the importance of compatibility between hardware and control systems. Before finalizing your selection, verify that the board supports your current infrastructure and meets your operational requirements.

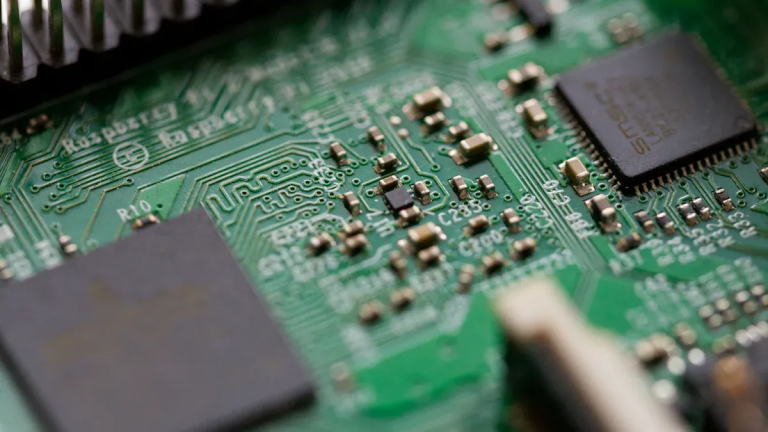

Input/output (I/O) requirements

Input/output (I/O) configurations play a critical role in determining the functionality of industrial control panels. Assess the number and type of I/O ports required for your application. For instance, programmable logic controllers (PLCs) often demand specific I/O setups to handle sensors, actuators, and other connected devices. A mismatch in I/O requirements can lead to inefficiencies or system failures. Consulting with a control panel shop can provide valuable advice on selecting a board with the right I/O capabilities.

Software and Firmware Considerations

Lifecycle management and updates

Effective lifecycle management ensures your industrial control board remains operational and up-to-date. Regular firmware updates and software maintenance are crucial for addressing vulnerabilities and improving performance. According to industry reports, lifecycle considerations often involve evaluating the cost and performance trade-offs between commercial off-the-shelf (COTS) components and custom solutions. For example:

| Topic | Details |

|---|---|

| COTS vs. Custom | Balances cost-effectiveness with tailored functionality. |

| Lifecycle Considerations | Addresses component obsolescence and long-term maintenance needs. |

Planning for these factors can save time and money while ensuring your system stays reliable.

Compatibility with existing platforms

Software compatibility is another critical factor in PLC selection advice. The board’s software must align with your existing platforms to avoid integration challenges. For instance, requesting circuit board design files, such as schematics and layouts, can simplify future modifications. Additionally, choosing a board that supports popular programming languages like C/C++ ensures smoother integration with your current systems.

Communication Protocols

Support for Modbus, Ethernet/IP, Profinet, etc.

Communication protocols like Modbus and Ethernet/IP are vital for enabling efficient data exchange between devices. Modbus, for example, is widely accepted in the industry due to its reliability and ease of implementation. It facilitates quick communication and enhances data collection, making it a preferred choice for many industrial applications. Selecting a board that supports these protocols ensures seamless interoperability.

Interoperability with other devices

Interoperability is key to achieving a cohesive industrial system. Protocols like Profinet group messages into conformance classes, helping you identify essential messages for device compatibility. This approach simplifies integration and ensures your industrial control panels work harmoniously with other devices. Prioritizing interoperability during the selection process can significantly improve system efficiency and reliability.

Cost Considerations for Choosing the Right Industrial Control Panel

Initial Investment

Comparing prices and quality

When selecting industrial control panels, balancing price and quality is essential. High initial investment costs can deter small and medium-sized enterprises, but opting for cheaper alternatives may compromise performance and durability. A properly functioning industrial control panel must meet your operational needs while adhering to safety standards. For example, compliance with UL 508A ensures reliability and safety, even in demanding environments.

| Factor | Importance |

|---|---|

| Initial Investment Costs | Advanced panels may require significant upfront costs but offer long-term benefits. |

| Compliance and Safety | Ensures adherence to safety standards, reducing risks and liabilities. |

| Quality vs. Price | High-quality panels reduce repair frequency and downtime losses. |

Balancing cost with performance

The total cost of ownership (TCO) provides a comprehensive view of financial implications. While high-quality panels may have a higher purchase price, they often lead to fewer repairs and lower downtime costs. Tailoring the panel to your specific needs ensures optimal performance without unnecessary expenses. For instance, investing in a modular design can save costs on future upgrades, making it a cost-effective choice.

Total Cost of Ownership

Maintenance and repair expenses

Maintenance and repair costs significantly impact the TCO of industrial control panels. Regular upkeep ensures the panel remains operational and prevents costly breakdowns. Life cycle cost analysis (LCCA) evaluates these expenses, helping you identify the most cost-effective solutions. For example, choosing a durable industrial control board reduces the frequency of repairs, saving money over time.

Long-term support and warranties

Long-term support and warranties are critical for minimizing unexpected expenses. A reliable manufacturer or control panel shop often provides extended warranties, covering defects and malfunctions. This support ensures your industrial controller operates efficiently throughout its lifecycle. Additionally, access to technical advice and programming updates enhances the panel’s longevity.

Energy Efficiency

Evaluating power consumption

Energy efficiency is a key factor in reducing operational costs. Modern industrial control panels often include energy-saving features, such as optimized power supplies and efficient PLC software. Evaluating the panel’s power consumption helps you identify opportunities to lower energy usage without compromising performance.

Reducing operational costs

Energy-efficient panels not only reduce electricity bills but also contribute to sustainability goals. For example, panels with advanced programming capabilities can optimize energy usage during peak hours. This approach minimizes waste and ensures a properly functioning industrial control panel operates at maximum efficiency.

Tip: Consult with a control panel shop to explore energy-efficient options tailored to your specific needs.

Advice for Selecting a Reliable Manufacturer or Supplier

Choosing the right vendor is critical when investing in industrial control panels. A reliable manufacturer ensures you receive high-quality products and dependable support. Below are key factors to consider during your vendor selection process.

Manufacturer Reputation

Customer reviews and industry track record

Start by researching customer reviews and testimonials. These provide valuable insights into the manufacturer’s reliability and product quality. Look for consistent positive feedback, especially regarding the performance of their industrial control panels. A strong industry track record also indicates the manufacturer’s ability to meet diverse client needs. Companies with a history of delivering durable and efficient industrial control boards are often more trustworthy.

Longevity and reliability in the market

A manufacturer’s longevity in the market reflects their stability and expertise. Long-standing companies often have refined manufacturing processes and a deeper understanding of industry trends. This experience translates into better product quality and innovative solutions. Prioritize vendors with a proven history of producing reliable industrial controllers and offering excellent customer service.

Support and Services

Availability of technical support

Technical support is essential for troubleshooting and maintaining your industrial control panels. Ensure the manufacturer provides accessible and responsive support channels. Quick assistance minimizes downtime and keeps your operations running smoothly. Some vendors also offer on-site support, which can be invaluable for resolving complex issues.

Training and documentation resources

Comprehensive training and detailed documentation simplify the integration and operation of your industrial control board. Look for manufacturers that provide user manuals, programming guides, and training sessions. These resources empower your team to operate and maintain the equipment effectively, reducing reliance on external support.

Warranty and Return Policies

Coverage for defects and malfunctions

A robust warranty demonstrates the manufacturer’s confidence in their products. Review the warranty terms to understand what is covered, such as defects or malfunctions. This coverage protects your investment and ensures you receive a properly functioning industrial control panel.

Flexibility in returns or replacements

Flexible return and replacement policies are equally important. They provide peace of mind, especially if the product does not meet your expectations or arrives damaged. A reliable manufacturer will prioritize customer satisfaction by offering hassle-free returns and replacements.

Tip: Consult a control panel shop for additional advice on vendor selection. Their expertise can help you identify manufacturers that align with your specific needs.

Selecting the right industrial control board requires careful consideration of your operational needs, compliance standards, and system compatibility. Evaluating these factors ensures your industrial control panels perform efficiently and meet safety requirements. Prioritize cost-effectiveness by balancing initial investment with long-term benefits like energy efficiency and durability. Seek expert advice to navigate the selection process and identify the best solution for your application. A well-chosen industrial controller not only enhances current operations but also supports future growth. Take the time to research and make an informed decision that aligns with your goals.

FAQ

What is the most important factor when choosing an industrial control board?

The most important factor is understanding your application needs. Evaluate operational requirements, scalability, and compatibility with existing systems. This ensures the board meets your performance goals and integrates seamlessly into your setup.

How do you ensure regulatory compliance during selection?

Check for certifications like UL 508A or EN 60204-1. These standards confirm the board meets safety and operational requirements. Always verify regional and industry-specific compliance to avoid penalties or operational risks.

Can you upgrade an industrial control board later?

Yes, modular designs allow for upgrades without replacing the entire system. This flexibility supports future technological advancements and changing operational demands, making it a cost-effective choice.

How do you balance cost and performance?

Compare initial investment with long-term benefits. High-quality boards may cost more upfront but reduce maintenance expenses and downtime. Prioritize energy-efficient options to lower operational costs over time.

Why is manufacturer reputation important?

A reputable manufacturer ensures product quality and reliable support. Look for companies with positive customer reviews, a strong industry track record, and comprehensive warranties. This minimizes risks and ensures long-term satisfaction.