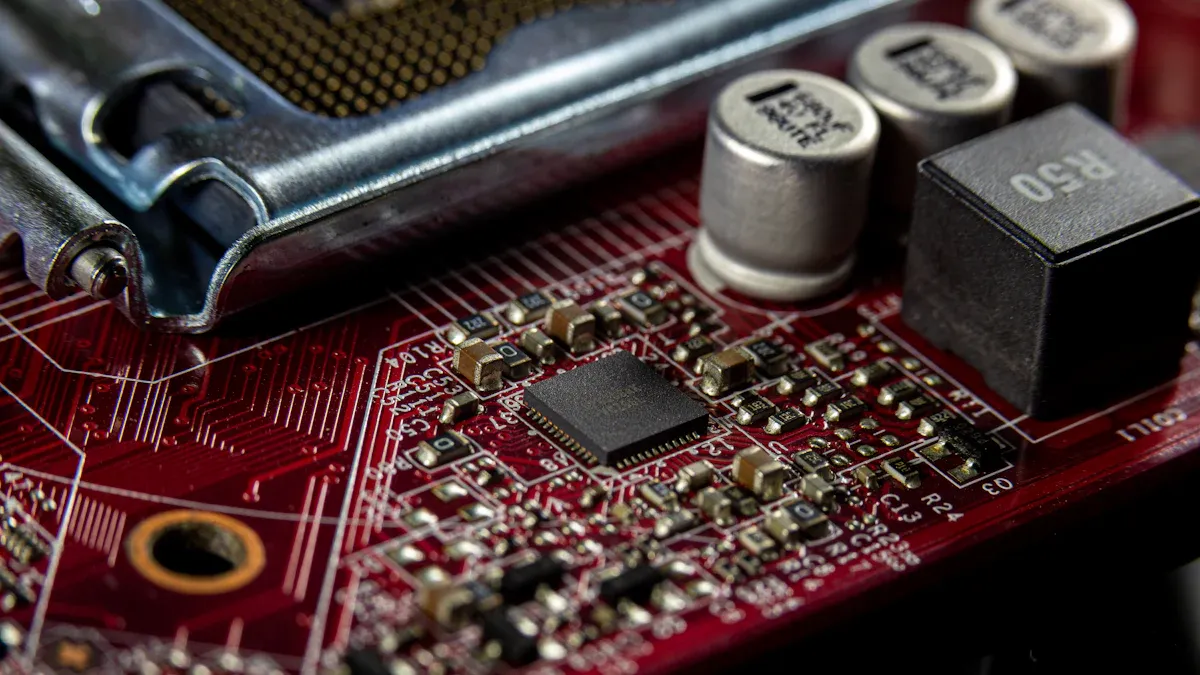

Finding the right PCB assembly manufacturer can make or break your project. A trusted electronics manufacturing company ensures your printed circuit boards meet high standards, perform reliably, and arrive on time. You need to evaluate their quality, experience, and services carefully. The best PCB manufacturer will offer transparency, strong customer support, and proven expertise. However, watch for red flags like hidden fees, poor communication, or missed deadlines. A reliable PCB manufacturer not only delivers results but also builds trust, ensuring your success with every project.

Key Takeaways

- Check for important certifications like ISO and RoHS. These show the PCBs are safe and meet good standards.

- Look at the manufacturer’s experience and skills. Find one with a strong history and knowledge in your field to avoid problems.

- Think about the services they offer. A good manufacturer should help with prototyping and testing to fit your project needs.

- Make sure they deliver on time. Pick a manufacturer known for meeting deadlines to avoid delays.

- Read customer reviews and look for warning signs. Good reviews mean they are trustworthy, but complaints about communication or extra fees could be trouble.

Evaluate Quality and Standards Compliance

When choosing a PCB assembly manufacturer, you must evaluate quality and standards compliance to ensure your project meets high standards of quality. This step guarantees that your PCBs perform reliably and align with industry expectations. Here’s how you can assess this critical aspect:

Certifications to Look For (e.g., ISO, IPC)

Certifications are a clear indicator of a manufacturer’s commitment to quality. Look for these key certifications when evaluating a PCB manufacturer:

| Certification | Scope | Impact on PCB Quality Assurance |

|---|---|---|

| RoHS | Limits hazardous substances in PCB materials | Ensures environmentally compliant production, reducing exposure to harmful substances |

| UL | Focuses on safety and fire resistance of PCBs | Confirms that PCBs meet safety standards, especially for fire resistance and electrical stability |

| ISO 9001 | Quality management system for continuous improvement | Establishes a foundation for consistent quality, performance, and customer satisfaction |

| IPC-A-600 | Defines acceptable standards for PCB appearance and integrity | Ensures PCBs meet performance expectations and minimize defect rates |

These certifications not only ensure high-quality PCBs but also enhance product reliability and customer satisfaction. A certified manufacturer demonstrates their dedication to maintaining high standards of quality.

Quality Control and Testing Processes

Quality control is the backbone of reliable PCB assembly. Manufacturers that prioritize quality control implement rigorous testing processes to deliver high-quality PCBs. During production, they perform:

- Incoming Material Inspection: Ensures components meet required specifications.

- Component Verification: Uses advanced techniques like X-ray inspection to detect defects.

- Testing and Inspection: Includes Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing.

| Testing Method | Description |

|---|---|

| Automated Optical Inspection (AOI) | Uses cameras to identify defects like misaligned components and soldering issues. |

| In-Circuit Testing (ICT) | Tests the electrical performance of individual components to detect faults. |

| Functional Testing | Verifies that the PCB performs its intended function under simulated conditions. |

By exploring testing options like these, you can ensure your PCBs meet high standards of quality. Manufacturers that follow strict quality control processes reduce defect rates and improve overall reliability.

Adherence to Industry Standards

Adhering to international industry standards is essential for producing high-quality PCBs. Standards like IPC and ISO ensure consistency, reliability, and environmental sustainability. They also promote seamless workflows and better communication among contributors. For example:

| Benefit | Explanation |

|---|---|

| Enhanced product value and consistency | Following IPC standards leads to high-quality products, improving reliability and customer satisfaction. |

| Better communication among contributors | Common standards facilitate clear communication, reducing ambiguity and enhancing collaboration. |

| Improved brand identity in the market | Adhering to standards builds brand value and reputation, indicating commitment to quality. |

| Lower cost | Improved supply-chain efficiency reduces resource requirements and production costs. |

| Seamless workflow | Following standards reduces faults and delays, ensuring smooth development and assembly processes. |

When you work with a PCB assembly manufacturer that adheres to these standards, you gain confidence in their ability to deliver high-quality results. This commitment to quality and standards compliance ensures your project’s success.

Assess Experience and Expertise

When selecting a PCB assembly manufacturer, their experience and expertise play a pivotal role in ensuring your project’s success. A company with a proven track record, specialized knowledge, and documented case studies can provide the confidence you need to move forward.

Proven Track Record of the PCB Assembly Company

A strong track record demonstrates a company’s ability to deliver consistent results. Look for performance metrics that validate their reliability and technical capabilities. For example:

| Performance Metric | Description |

|---|---|

| On-time Delivery | Consistently meeting deadlines, which is crucial for maintaining your project timeline. |

| Flexible Production Capabilities | Adapting to urgent orders or unexpected demand spikes without compromising quality. |

| Technical Expertise | Handling complex technical requirements in advanced electronics with precision. |

| Quality Control Measures | Implementing rigorous checks to ensure every product meets industry standards. |

| Certifications | Adhering to standards like ISO 9001 and AS9100, showcasing their commitment to quality management. |

These metrics highlight the importance of choosing a PCB assembly company that prioritizes quality and reliability.

Specialized Knowledge in Your Industry

Every industry has unique requirements, and a manufacturer with specialized knowledge can make all the difference. Experienced contractors bring invaluable expertise to the table. They can identify potential design flaws early, preventing costly mistakes. Their familiarity with industry standards ensures compliance and safety, which directly enhances product quality. By working with a manufacturer who understands your industry’s nuances, you gain a partner who can anticipate challenges and deliver tailored solutions.

- Specialized contractors improve efficiency by streamlining processes.

- They ensure compliance with industry standards, boosting product reliability.

- Their proactive approach minimizes risks and maximizes quality.

Case Studies and Past Projects

Case studies and past projects provide tangible proof of a manufacturer’s expertise. For instance, one case study revealed that 80% of non-value-added costs in a product stemmed from just two types of manufacturing defects. This insight underscores the importance of working with a manufacturer who prioritizes quality control and defect prevention. Reviewing documented successes allows you to evaluate how a manufacturer has tackled challenges similar to yours. It also gives you a clear picture of their ability to deliver high-quality results consistently.

By assessing a manufacturer’s experience and expertise, you ensure your project is in capable hands. The best PCB manufacturer will combine technical proficiency with a deep understanding of your needs, delivering exceptional quality every time.

Manufacturing Capabilities and Services

When selecting a PCB assembly manufacturer, their manufacturing capabilities and services should align with your project’s needs. A company with advanced technology, diverse services, and scalability ensures your project’s success from start to finish.

Range of Capabilities Offered by the PCB Assembly Manufacturer

The best PCB manufacturer offers a wide range of capabilities to meet diverse project requirements. Whether you need quickturn PCBs or complex designs, their expertise ensures high-quality results. Here’s what you should look for:

| Capability/Service | Description |

|---|---|

| Assembly Options | Surface Mount (SMT), Thru-Hole (THT), and hybrid options available. |

| Types of Solder | Both leaded and lead-free (RoHS Compliant) assembly services offered. |

| Component Size | Accepts components as small as 01005, with capabilities for BGA of 0.3mm pitch. |

| Board Dimension | Min Board Size: 10mm x 10mm; Max Board Size: 250mm x 500mm. |

| Repair & Rework | Offers BGA reballing service for cost-effective repair. |

| Testing Procedures | Includes visual inspection, X-ray inspection, AOI testing, ICT, and functional tests. |

| ISO Certification | Facilities are ISO9001 certified with a quality complaint rate ≤ 0.1%. |

These capabilities ensure your circuit board manufacturing process is efficient and reliable. Advanced technologies and rigorous quality control measures improve board quality and customer satisfaction.

Additional Services (e.g., prototyping, design support)

A reliable PCB assembly service goes beyond manufacturing. Look for additional services like prototype circuit board production and design support. Prototyping allows you to test and refine your designs before full-scale production, saving time and money. Design support ensures your boards meet functional and quality standards. These services streamline the process, reduce errors, and enhance the final product.

For example, a PCB assembly company offering quickturn PCBs can accelerate your project timeline without compromising quality. This flexibility is invaluable when you’re working on tight deadlines or iterative designs.

Scalability for Different Project Sizes

Your PCB manufacturer should scale their services to match your project size. Whether you need a single prototype circuit board or a large production run, they should adapt to your requirements. Companies with flexible production capabilities can handle urgent orders or unexpected demand spikes. This scalability ensures you receive consistent quality, regardless of the project’s scope.

By choosing a manufacturer with scalable services, you future-proof your projects. As your needs grow, they’ll have the capacity to support you without delays or compromises in quality.

Turnaround Time and Delivery

Timely delivery is crucial when selecting a PCB assembly manufacturer. A quick-turn PCB manufacturer that meets deadlines ensures your project stays on track and avoids costly delays. Here’s how you can evaluate their turnaround time and delivery performance.

Meeting Deadlines and Production Schedules

A reliable PCB assembly company prioritizes meeting deadlines. Top manufacturers achieve on-time delivery rates as high as 98%, ensuring your project progresses smoothly. For example, companies like PCBWay and JLCPCB offer turnaround times ranging from 24 hours to a few days for simple boards. This speed allows you to meet tight deadlines without compromising quality.

| Manufacturer | Typical Turnaround Time | Pricing | Quality Management |

|---|---|---|---|

| PCBWay | 24 hours to a few days | Competitive, lower than US-based | ISO 9001 certified, with reported quality variations |

| JLCPCB | 24 hours to a few days | Very competitive | ISO 9001 certified, consistent quality |

When evaluating a manufacturer, ask about their production schedules and adherence rates. A company with a proven track record of timely delivery demonstrates reliability and experience.

Flexibility in Lead Times

Flexibility in lead times is another critical factor. A quick-turn PCB manufacturer should adapt to your project’s needs, whether you require a next-day delivery or a longer production cycle for complex assemblies. For instance, average lead times for PCB assembly range from 1-5 working days, while turn-key services may take 10-16 working days. This flexibility ensures you can scale production without sacrificing quality or efficiency.

Manufacturers that offer expedited services for urgent projects provide a significant advantage. They help you respond to market demands quickly, giving you a competitive edge.

Shipping and Logistics Support

Shipping and logistics play a vital role in ensuring your PCBs arrive on time and in perfect condition. On-time shipping, order accuracy, and delivery speed directly impact customer satisfaction. Late shipments can disrupt your project timeline and lead to financial losses. A dependable PCB manufacturer provides robust logistics support, including tracking systems and reliable shipping partners.

Look for a manufacturer that prioritizes order accuracy and offers transparent communication throughout the shipping process. This attention to detail minimizes errors and ensures a seamless delivery experience.

By choosing a quick-turn PCB manufacturer with strong delivery performance, you can meet your deadlines, maintain quality, and achieve project success.

Customer Support and Communication

Responsiveness and Accessibility

When working with a PCB manufacturer, you need a partner who values your time and responds promptly. Excellent customer service begins with accessibility. A reliable manufacturer ensures you can reach their team through multiple channels, such as email, phone, or live chat. Quick responses to your inquiries demonstrate their commitment to your project’s success.

Responsiveness can be measured using key performance indicators (KPIs). For example, metrics like lead time, downtime, and rework rates reflect how efficiently a manufacturer addresses your needs. Here’s a quick overview of relevant KPIs:

| KPI | Description |

|---|---|

| Lead Time | Time from order placement to delivery, crucial for customer satisfaction. |

| Downtime | Time when production equipment is non-operational, impacting overall efficiency. |

| Rework and Repair Rate | Percentage of products needing rework, indicating quality control effectiveness. |

By choosing a manufacturer with strong responsiveness, you ensure your project stays on track without unnecessary delays.

Transparency in Communication

Clear communication builds trust. A PCB manufacturer that prioritizes transparency keeps you informed about project timelines, pricing, and potential challenges. This openness helps you manage expectations and avoid surprises. Positive feedback often correlates with transparent communication, while unclear updates can lead to frustration.

To foster trust, look for manufacturers who provide detailed project updates and clear pricing structures. They should also proactively inform you about any delays or issues. This level of transparency ensures you remain confident in their ability to deliver high-quality results.

Post-Sales Support and Issue Resolution

Your relationship with a PCB manufacturer doesn’t end after delivery. Post-sales support is critical for addressing any issues that arise. A manufacturer offering excellent customer service will assist you with troubleshooting, repairs, or replacements. They’ll also provide guidance to prevent future problems.

Effective post-sales support includes quick issue resolution and a willingness to go the extra mile. For instance, if a defect occurs, a reliable manufacturer will investigate the root cause and implement corrective actions. This dedication to quality ensures your long-term satisfaction and strengthens your partnership.

Pricing and Value for Money

Balancing Cost and Quality

When choosing a PCB assembly manufacturer, balancing cost and quality is essential. While it may be tempting to opt for the cheapest option, this often leads to inferior products that require costly reworks or replacements. Investing in quality upfront saves you time and money in the long run. Manufacturers offering higher-cost services often deliver superior quality, ensuring your PCBs perform reliably and meet industry standards.

Several factors influence pricing, including board complexity, assembly technology, and order quantity. For example:

- Board complexity: More layers and higher component density increase costs.

- Assembly technology: Surface Mount Technology (SMT) is more cost-effective for high-volume production, while Through-Hole assembly incurs higher labor costs.

- Order quantity: Larger orders benefit from economies of scale, reducing per-unit costs.

Remember, the best PCB manufacturer balances price and quality, ensuring you receive value for your investment.

Transparency to Avoid Hidden Fees

Transparency in pricing is critical when selecting a PCB assembly company. Hidden fees can derail your budget and cause unnecessary frustration. To avoid surprises, request a detailed cost breakdown that includes material sourcing, assembly, and setup fees.

Leading manufacturers provide clear pricing structures and offer discounts for larger volumes or specific assembly types. For example:

- Setup fees: These are often fixed costs for tooling and preparation.

- Minimum order quantities (MOQs): Larger orders typically reduce per-unit costs.

- Volume discounts: Bulk orders can lead to significant savings.

Be cautious of low-cost providers that may include hidden costs or delays. A transparent PCB manufacturer ensures their pricing aligns with your budget, giving you confidence in their reliability.

Long-Term Cost Efficiency

Investing in high-quality PCB assembly services pays off in the long term. Beyond initial production costs, operational expenses like maintenance and quality control impact overall efficiency. Manufacturers that prioritize automation and Design for Manufacturability (DFM) reduce costs while enhancing quality.

| Evidence Type | Description |

|---|---|

| Economies of Scale | Higher volume orders lower per-unit costs through negotiation. |

| Design for Manufacturability (DFM) | Simplified designs reduce layers and control expenses. |

| Automation | Advanced inspection systems improve efficiency and reduce defects. |

Bulk supply procurement and partnerships with reliable assembly houses further optimize costs. By choosing a PCB assembly company that focuses on long-term efficiency, you ensure consistent quality and cost savings for future projects.

Reputation and Reviews

When choosing a PCB assembly manufacturer, their reputation speaks volumes about their reliability and quality. By researching reviews and feedback, you can gain valuable insights into their performance and customer satisfaction. Here’s how to evaluate their reputation effectively.

Researching Customer Feedback

Customer reviews are a goldmine of information. They reveal how well a PCB assembly company meets expectations in terms of quality, delivery, and support. Look for feedback on forums, social media, and industry-specific platforms. Pay attention to recurring themes in customer reviews, such as consistent quality or frequent delays. These patterns help you identify strengths and weaknesses.

Quantifiable data from customer feedback surveys can also guide your decision. For example:

| Report Title | Metrics Covered |

|---|---|

| Industry Report | Production data, defect rates, customer satisfaction, supplier performance |

| IPC Study of Quality Benchmarks for Electronics Assembly 2019 | Production data, defect rates, customer satisfaction, cost of rework |

| IPC-Benchmark Study 2017 | Production data, defect rates, customer satisfaction, assembly attributes |

These reports provide measurable insights into the reputation of PCB suppliers, helping you make an informed choice.

Online Reviews and Testimonials

Online reviews and testimonials offer firsthand accounts of customer experiences. Check platforms like Google Reviews, Trustpilot, or the manufacturer’s website. Positive reviews often highlight exceptional quality, timely delivery, and strong customer support. On the other hand, negative reviews may point out red flags, such as hidden fees or poor communication.

Testimonials from long-term clients carry extra weight. They indicate that the PCB manufacturer consistently delivers value and builds trust over time. Use these reviews to assess whether the company aligns with your expectations.

Watch for Red Flags in Reputation

While researching, stay alert for red flags that could signal potential issues. Common warning signs include:

- Frequent complaints about missed deadlines or defective products.

- A lack of transparency in pricing or communication.

- Poor post-sales support, such as unresolved issues or unresponsive service.

If you notice these patterns, it’s best to explore other options. A strong reputation reflects a manufacturer’s commitment to quality and customer satisfaction. By avoiding companies with red flags, you protect your project from unnecessary risks.

Choosing the right PCB assembly manufacturer is critical to your project’s success. By evaluating quality, experience, and manufacturing capabilities, you ensure your PCBs meet industry standards and perform reliably. Balancing cost, quality, and delivery timelines helps you achieve long-term value without compromising on performance. Always watch for red flags like hidden fees or poor communication, as these can derail your project. Conduct thorough research and partner with a PCB manufacturer that prioritizes transparency and customer satisfaction. This approach guarantees a reliable and efficient manufacturing process, setting your project up for success.

FAQ

What should you prioritize when choosing a PCB manufacturer?

Focus on quality, certifications, and customer support. A reliable PCB manufacturer ensures your boards meet industry standards and perform consistently. Evaluate their track record and manufacturing capabilities to ensure they align with your project needs.

How does a manufacturer’s experience impact your project?

A manufacturer with extensive experience delivers better results. They understand industry-specific requirements and anticipate challenges. Their expertise ensures high-quality PCBs, timely delivery, and fewer production errors, saving you time and money.

Can you request prototypes before full production?

Yes, most manufacturers offer prototyping services. Prototypes allow you to test and refine your design before committing to large-scale production. This step minimizes risks and ensures your final product meets expectations.

How do you ensure timely delivery of PCBs?

Choose a manufacturer with a proven track record of meeting deadlines. Ask about their production schedules and flexibility in lead times. Reliable logistics support also ensures your PCBs arrive on time and in perfect condition.

What certifications should a PCB manufacturer have?

Look for certifications like ISO 9001, IPC-A-600, and RoHS compliance. These certifications guarantee quality, safety, and environmental responsibility. A certified manufacturer demonstrates their commitment to delivering reliable and high-quality PCBs.