Excavator PCBA boards are important for your machine to work well. Keeping them safe helps avoid expensive repairs and keeps them working right. Things like water or very hot and cold weather can harm them. Not taking care of them or using them wrong can also cause damage. By being careful, you can make these parts last longer. This also helps your machine work better for a long time. It means fewer repairs and better performance, even in tough conditions.

Key Takeaways

- Clean your excavator PCBA boards often to remove dirt. This helps stop overheating and short circuits.

- Check boards regularly for damage like rust or loose parts. Finding problems early can save money on repairs.

- Keep PCBA boards in places with steady temperature and humidity. This prevents rust and damage from the environment.

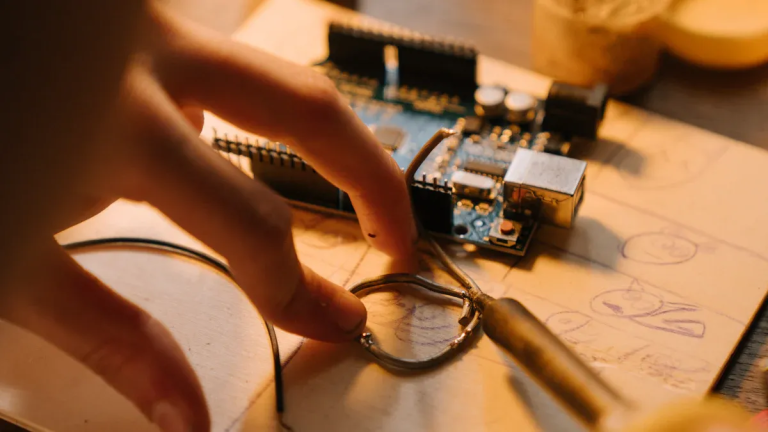

- Use anti-static tools and handle boards gently to avoid harm from static electricity or bumps.

- Add protective coatings to shield boards from moisture and dust. This makes them last longer and work better.

Understanding Excavator PCBA Boards

What Are Excavator PCBA Boards?

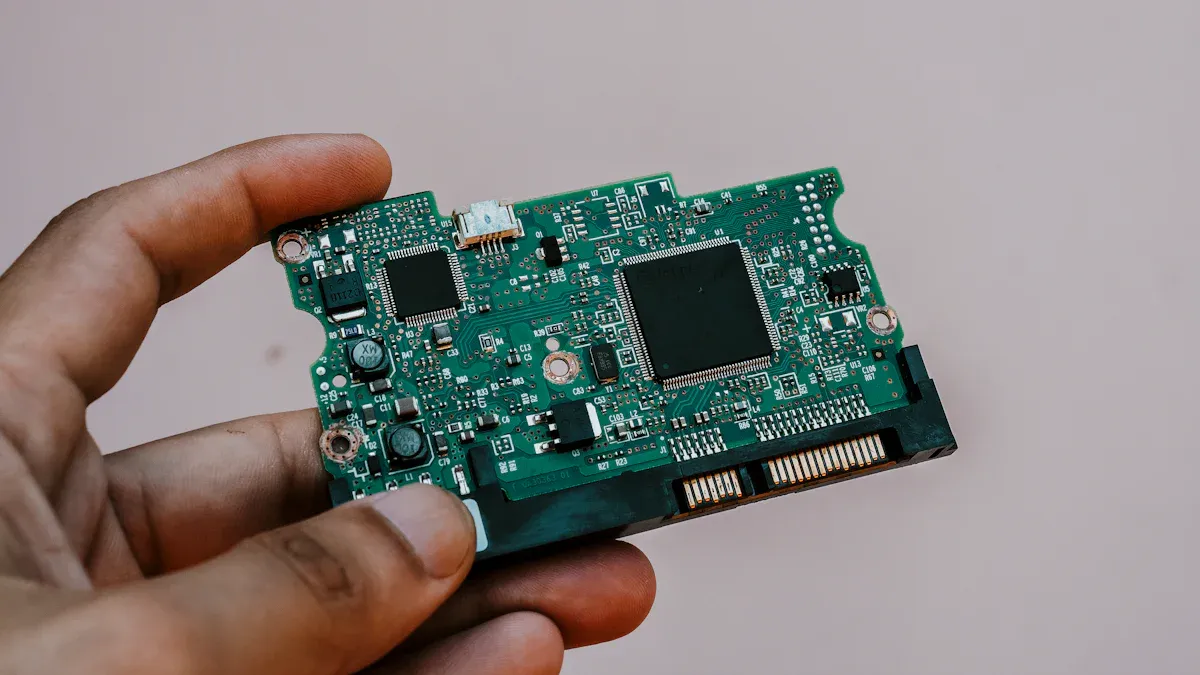

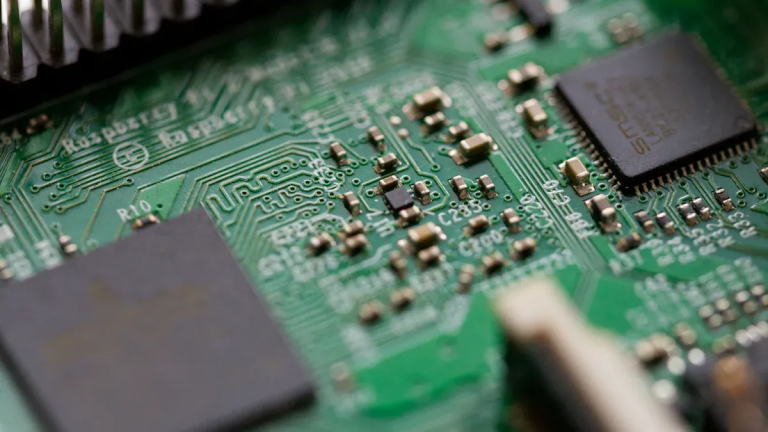

Excavator PCBA boards are key to your excavator’s electronics. These boards hold parts like resistors, capacitors, and connectors. They work together to control how the machine operates. Unlike basic circuit boards, PCBA boards are fully built and ready to use.

These boards are designed to handle tough working conditions. They are made with strong materials like FR-4 and have multiple layers. This helps them resist vibrations, extreme heat or cold, and moisture. Below is a table showing some details about a typical excavator PCBA board:

| Specification | Details |

|---|---|

| Model NO. | GT-PCBA |

| Layers | Multilayer |

| Base Material | FR-4 |

| Certification | RoHS, CCC, ISO |

| Assembly Methods | SMT, THT & Hybrid, single or double side placement |

| PCB Panel Size | Min: 0.25×0.25 inches (6×6mm), Max: 20×20 inches (500×500mm) |

| Inspection & Testing | Visual Inspection, AOI, SPI, X-ray inspection, etc. |

| Surface Finishes | ENIG, HASL lead-free, OSP, etc. |

Functions of PCBA Boards in Excavators

PCBA boards are important for controlling your excavator’s systems. They manage things like engine performance, hydraulic controls, and safety features. These boards help all parts work together so the machine runs smoothly.

For example, connectors on the board link sensors and actuators. This allows the machine to share data and adjust to changes, like heavy loads or rough ground. If these boards fail, it can cause problems or safety issues.

Why PCBA Boards Require Good Circuit Board Maintenance

Taking care of PCBA boards keeps your excavator working well. Skipping maintenance can cause dirt buildup, rust, or even board failure. Cleaning and checking them often can stop these problems and make the boards last longer.

Good maintenance also saves time and money on repairs. For instance, using anti-static tools and storing boards safely can prevent damage. These steps help your PCBA boards last longer and keep your excavator performing its best.

Common Causes of PCBA Board Damage

Environmental Risks

Moisture and Humidity

Water in the air can harm excavator PCBA boards. Too much humidity can cause rust, which weakens parts over time. This is worse in places with lots of rain or dampness. Special coatings, like conformal coatings, can protect the board. Studies show that wet conditions make rust happen faster, especially underwater or in damp areas.

| Environmental Condition | Effect on PCBA Boards |

|---|---|

| Humidity | Leads to rust and weakens parts over time. |

| Moisture | Raises rust risk, especially in wet environments. |

Extreme Temperatures

PCBA boards face tough weather. Very hot temperatures can stress parts and lower performance. Freezing cold can shrink parts, causing cracks or breaks. Good airflow and heat-resistant materials help avoid these problems.

Dirt and Dust

Dust and dirt can pile up on PCBA boards. This can cause overheating or short circuits. Construction sites often have this issue. Covering boards or using dust-proof cases keeps dirt out.

Handling Errors

Physical Damage

Rough handling can break PCBA boards. Dropping them or pressing too hard can crack parts or loosen connections. Always use safe tools and handle boards gently to prevent damage.

Electrostatic Discharge (ESD)

Static electricity can silently harm PCBA boards. Even a tiny shock can ruin sensitive parts. Anti-static wristbands and mats help stop this. Experts say ESD is a major cause of board failure, so careful handling is key.

Neglecting Maintenance

Dirt and Debris Accumulation

Skipping cleaning lets dirt build up on PCBA boards. This can cause overheating or short circuits. Cleaning every 3-6 months stops dirt damage and keeps boards working well.

Corrosion from Lack of Cleaning

Not cleaning also increases rust risk. Rust or discoloration shows the board is breaking down. Regular checks and cleaning stop this. Following maker instructions, like checking thermal grease, helps boards last longer.

Tip: Regular cleaning and checks are important to keep your excavator PCBA boards safe from damage caused by the environment or handling mistakes.

Preventive Maintenance for Excavator PCBA Boards

Cleaning Techniques

Recommended Tools and Materials

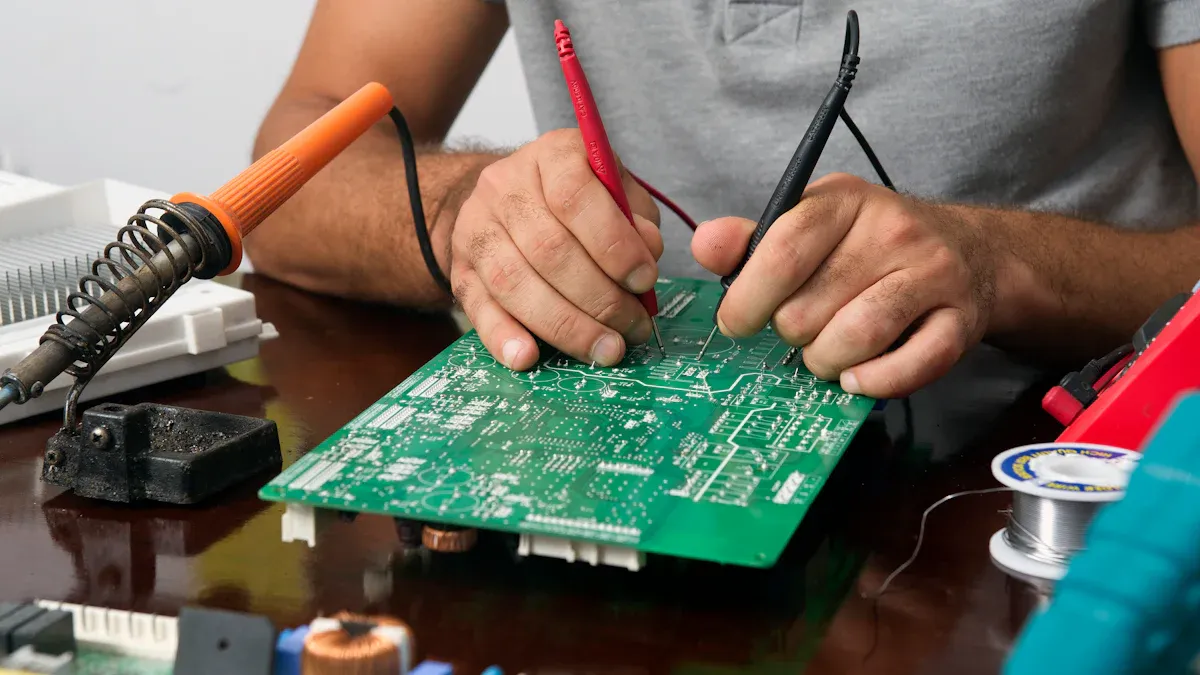

To clean your excavator PCBA boards, use the right tools. Compressed air helps remove dust from tight spaces. HEPA filter vacuums trap fine dust without harming the board. Soft brushes and lint-free cloths are great for gentle cleaning. For sticky dirt, use isopropyl alcohol and anti-static wipes. These tools clean well without causing rust or static damage.

Steps for Safe and Effective Cleaning

Follow these steps to clean your PCBA boards:

- Turn off the machine and unplug it from power.

- Blow away loose dust with compressed air.

- Use a soft brush to remove stuck dirt gently.

- Wipe the board with an anti-static cloth and alcohol.

- Let the board dry fully before plugging it back in.

Cleaning often stops dirt from causing overheating or short circuits. Keeping the area around your equipment clean also helps your PCBA boards last longer.

Inspection Routines

Identifying Early Signs of Damage

Check your PCBA boards often for damage. Look for rust, discoloration, or loose parts. Inspect for cracks or worn-out components. Finding problems early can save money and avoid downtime.

Setting Up Regular Inspection Schedules

Follow the maker’s advice for inspection schedules. Weekly quick checks and monthly detailed inspections work well. Use a maintenance tracking system to stay organized. Regular inspections help your PCBA boards last longer and prevent sudden failures.

Storage Practices

Controlled Environments for Storage

Store PCBA boards in safe places to avoid damage. Keep the temperature and humidity steady. Don’t let them face extreme weather or collect dust. Good storage keeps boards working longer and more reliably.

Avoiding Harmful Conditions

Keep boards away from things like electromagnetic or radio interference. Use anti-static bags and padded boxes to protect them. These steps reduce damage risks during storage.

Tip: Proper cleaning, inspections, and storage are key to keeping your excavator PCBA boards in good shape for a long time.

Environmental Protection for PCBA Boards

Moisture and Humidity Control

Protective Coatings and Sealants

Water in the air can harm PCBA boards badly. High humidity causes rust, peeling, or even electrical problems. Adding protective coatings, like conformal coatings or sealants, blocks moisture. These coatings protect delicate parts from damage, keeping them strong. Studies show that boards sensitive to water, especially with lead-free solder, can peel in wet conditions. This proves why protection is needed to keep them working well.

Using Dehumidifiers or Absorbers

Keeping the air dry is very important for PCBA boards. Dehumidifiers lower air moisture, stopping rust from forming. For smaller spaces, desiccant bags soak up extra moisture. These bags work well in storage boxes or machine compartments. By keeping things dry, your excavator PCBA boards can last much longer.

Temperature Regulation

Ensuring Proper Ventilation

Very hot or cold temperatures can hurt PCBA boards. Good airflow helps remove heat made during use. Adding cooling fans or heat sinks keeps the board cool. This stops overheating and protects parts from heat damage.

Avoiding Extreme Heat or Cold

Big temperature changes can also damage PCBA boards. Too much heat can weaken materials, and freezing can crack parts. Storing boards in places with steady temperatures avoids these problems. Keeping boards in a stable range helps them work better and last longer.

Dirt and Dust Prevention

Sealing and Covering PCBA Boards

Dust and dirt can pile up on PCBA boards, causing problems. Covering boards with protective cases stops dirt from settling. This is very helpful at construction sites where dust is common.

Using Dust-Proof Enclosures

Dust-proof cases give extra protection. These cases block tiny particles but still allow airflow. Cleaning regularly along with using these cases keeps PCBA boards clean and safe.

Tip: Check the table below for more ways to protect PCBA boards:

| Environmental Challenge | Control Technology/Measure |

|---|---|

| Vibration and Shock | Build PCBs to handle strong vibrations and shocks for durability. |

| EMI/RFI Interference | Use shields to block electromagnetic and radio-frequency interference. |

| Environmental Hazards | Add coatings and covers to guard against wind, sand, and debris. |

By following these steps, you can protect your excavator PCBA boards from damage and keep them working well for a long time.

Handling and Storage Best Practices

Safe Handling Methods

Anti-Static Tools and Equipment

Static electricity can harm your excavator PCBA boards without warning. Even a tiny shock can ruin delicate parts. To stop this, use anti-static tools like wrist straps, mats, and gloves. These tools keep you grounded and prevent static buildup. Make sure your workspace has ESD-safe surfaces and tools. Taking these steps can help you avoid expensive repairs or replacements.

Avoiding Direct Contact with Components

Touching PCBA parts with bare hands can leave oils or dirt. These can hurt the board’s performance over time. Always hold boards by their edges to avoid touching sensitive areas. If you need to touch the board, wear anti-static gloves. This simple habit helps protect the board and keeps it working well.

Proper Storage Conditions

Stable Temperature and Humidity Levels

Keeping PCBA boards in the right environment is very important. Big temperature changes or high humidity can cause rust or damage. Store boards in a place with steady temperatures, between 68°F and 77°F (20°C to 25°C). Use a dehumidifier to keep humidity below 60%. These steps help protect your boards and make them last longer.

Organizing Boards to Prevent Damage

Good storage keeps boards safe from scratches or bending. Use anti-static bags to block dust and static electricity. Place boards in padded containers or shelves with dividers. Don’t stack them to avoid damage. Label each board so you can find them easily. This method keeps boards safe and makes maintenance easier.

Tip: Check stored boards often to catch problems early. Fixing issues quickly saves time and money.

Taking care of excavator PCBA boards is very important. It helps avoid expensive repairs and keeps your machine working longer. Cleaning, checking, and protecting them from the environment can make them last.

- Regular checks find small problems early and stop big repairs.

- Cleaning removes dirt and keeps the boards working well.

- Protecting boards from water, dust, and heat keeps them safe.

Taking care of your boards saves money and improves performance. By following these steps, your PCBA boards will last longer, and your excavator will work better for years.

FAQ

How can you clean PCBA boards safely?

Blow off dust with compressed air. Use a soft brush for stuck dirt. For sticky spots, wipe gently with isopropyl alcohol and a lint-free cloth. Never use water or strong chemicals. Make sure the board is fully dry before putting it back.

How often should excavator PCBA boards be checked?

Do quick checks every week and detailed ones each month. Regular inspections help find rust, loose parts, or other damage early. This prevents expensive repairs and machine downtime.

Can very hot or cold temperatures harm PCBA boards forever?

Yes, extreme heat or cold can crack parts or weaken materials. It can also lower performance. Use good airflow and store boards in steady temperatures to avoid damage.

What tools are needed to handle PCBA boards safely?

Use anti-static wristbands, gloves, and mats. These stop static electricity from harming sensitive parts. Always hold boards by the edges to avoid touching important areas.

Why is keeping PCBA boards dry important?

Moisture can cause rust, corrosion, or electrical problems. Use protective coatings, dehumidifiers, or desiccant bags to keep boards dry. This is especially helpful in wet or humid places.

Tip: Taking care of your PCBA boards with regular checks and safe handling makes them last much longer.