Choosing the right PCB assembly partner plays a critical role in the success of your project. A poor selection can lead to serious consequences, including production delays, quality issues, and unexpected costs. These setbacks not only disrupt your supply chain but also shift your focus away from innovation and growth. By carefully evaluating factors like experience, technical capabilities, and quality assurance, you can prevent defects, reduce rework, and ensure reliable outcomes. A strong partnership guarantees that your final product meets industry standards while safeguarding your reputation and resources.

Key Takeaways

- Choose a PCB assembly partner with proven industry experience to ensure they can handle your project’s complexity and deliver high-quality results.

- Evaluate the technical expertise of potential partners, focusing on their ability to manage intricate designs and utilize advanced equipment for precision.

- Prioritize quality assurance processes and certifications, such as ISO 9001, to guarantee that your project meets industry standards and reduces the risk of defects.

- Look for a provider that offers a comprehensive range of services, including design assistance and testing, to streamline your project from start to finish.

- Ensure transparent pricing to avoid hidden costs and assess the overall value for money by considering quality, turnaround time, and support services.

- Assess customer support and communication effectiveness, as a responsive partner can help resolve issues quickly and keep your project on track.

- Consider the location of your PCB assembly partner to enhance collaboration, reduce shipping times, and improve supply chain efficiency.

Evaluating Experience and Expertise in PCB Assembly

Selecting a PCB assembly partner with the right experience and expertise ensures your project’s success. A provider with a proven track record can handle complex requirements and deliver high-quality results. By evaluating their industry experience and technical expertise, you can make an informed decision that aligns with your project goals.

Industry Experience

Industry experience reflects a provider’s ability to adapt to various challenges and deliver consistent results. Companies with years of experience in PCB assembly often have a deep understanding of industry standards and best practices. They are more likely to have worked on diverse projects, ranging from simple designs to intricate assemblies.

When assessing a provider’s experience, consider the types of assemblies they specialize in. For instance:

- Through-Hole Assembly: Ideal for larger components, this method offers excellent mechanical strength and stability.

- Surface Mount Assembly (SMT): Suitable for smaller components, SMT allows for higher component density and eliminates the need for drilling holes.

- Mixed Technology Assembly: Combines through-hole and SMT techniques, making it perfect for projects requiring both large and small components.

A provider experienced in these methods can tailor their services to meet your specific needs. Ask about their past projects and industries they have served. This insight helps you determine if they can handle your project’s complexity.

Technical Expertise

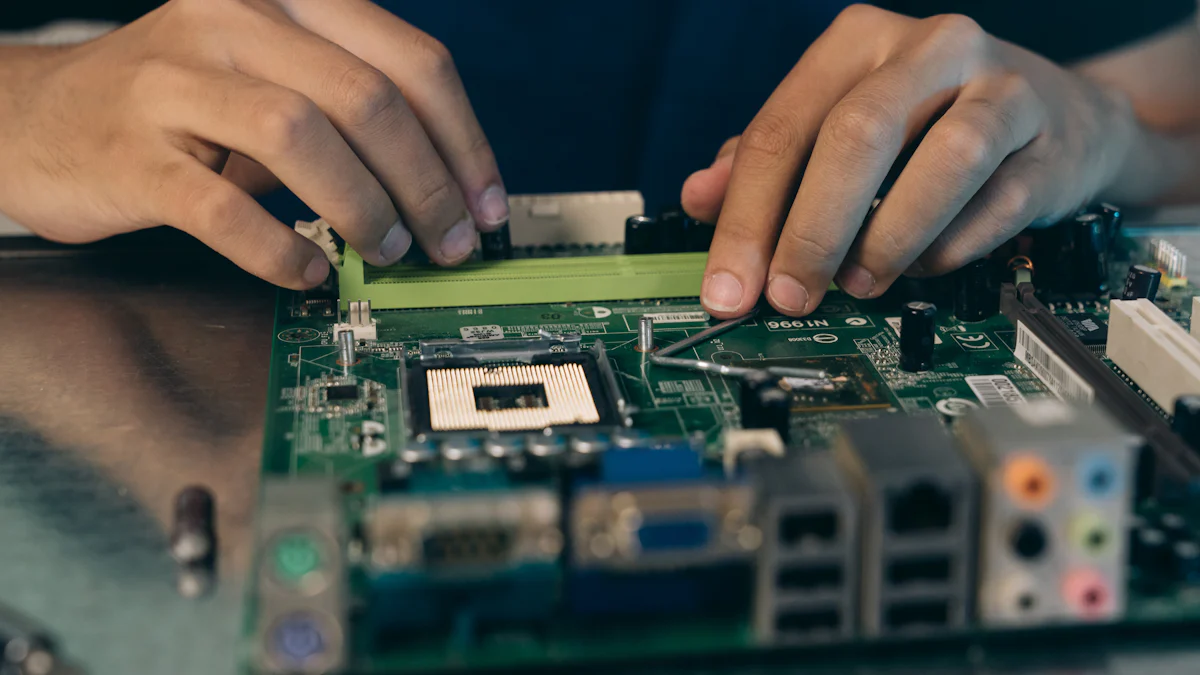

Technical expertise ensures that your PCB assembly partner can execute your design with precision. Providers with advanced technical skills can manage intricate layouts, high-density boards, and unique design requirements. Their ability to troubleshoot and resolve issues during the assembly process minimizes delays and defects.

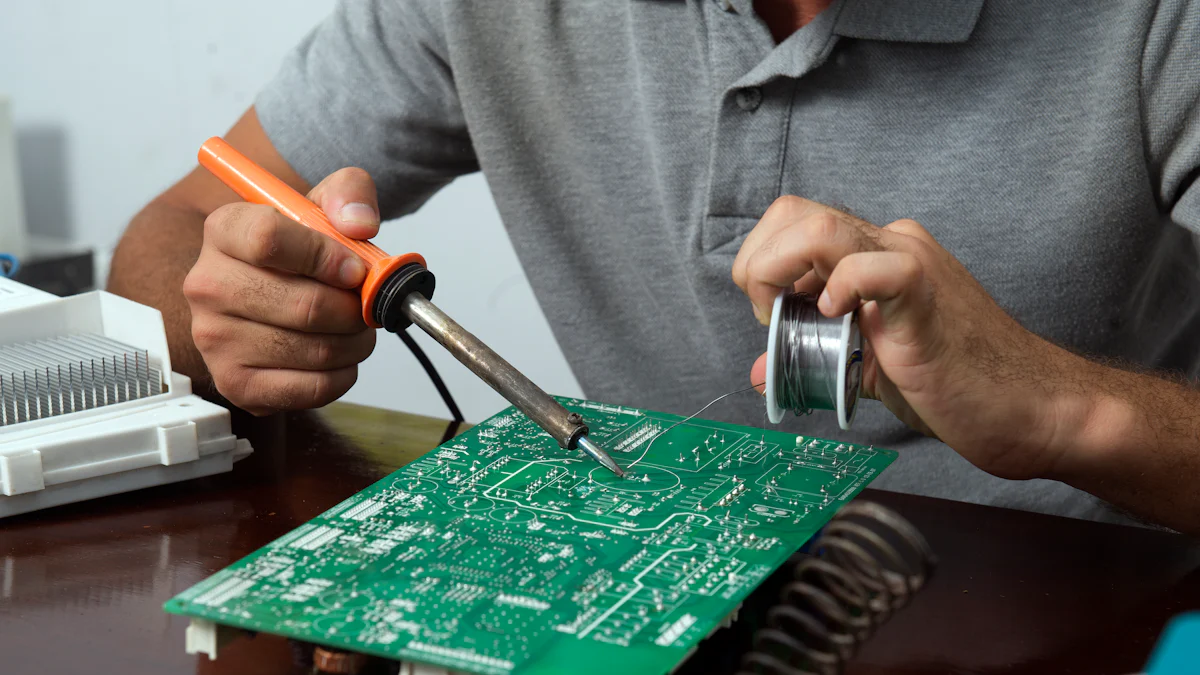

Evaluate their knowledge of modern equipment and technologies. Providers using state-of-the-art machinery can achieve higher accuracy and efficiency. For example, automated soldering machines and advanced inspection tools enhance the quality of the final product.

Additionally, inquire about their testing capabilities. Comprehensive testing, such as functional testing and in-circuit testing, identifies potential issues before the product reaches the market. This step ensures reliability and reduces the risk of costly rework.

By prioritizing industry experience and technical expertise, you can select a PCB assembly partner capable of delivering exceptional results. These factors form the foundation of a successful collaboration, ensuring your project meets its objectives.

Assessing Quality Assurance and Certifications in PCB Assembly

Ensuring quality in PCB assembly requires a thorough evaluation of a provider’s quality assurance processes and certifications. These elements guarantee that your project meets industry standards and performs reliably in real-world applications. By focusing on these aspects, you can minimize risks and ensure consistent results.

Quality Control Processes

Effective quality control processes are the backbone of reliable PCB assembly. Providers with robust systems in place can identify and address defects early, ensuring that every board meets your specifications. You should look for partners who implement stringent inspection and testing protocols throughout the assembly process.

Top-tier providers often use advanced tools like AI-powered Statistical Process Control (SPC) to monitor production quality in real time. This technology helps detect anomalies and maintain consistency across batches. Additionally, comprehensive testing methods, such as functional testing and in-circuit testing, ensure that components are correctly mounted and the board operates as intended.

When evaluating a provider, ask about their inspection stages. Reliable partners typically conduct:

- Pre-assembly inspections to verify component quality.

- In-process inspections to catch errors during assembly.

- Final inspections to confirm the board’s functionality and compliance with your requirements.

These steps reduce the risk of defects and costly rework, saving you time and resources.

Industry Certifications

Certifications serve as a benchmark for a provider’s commitment to quality and adherence to industry standards. A certified PCB assembly partner demonstrates their ability to deliver high-quality products while maintaining strict quality management practices.

Look for certifications such as:

- ISO 9001: Ensures a robust quality management system and consistent product quality.

- ISO 13485: Indicates expertise in medical device manufacturing, where precision and reliability are critical.

- AS9100D: Highlights compliance with aerospace industry standards, ensuring high performance and safety.

In addition to these, compliance with environmental regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) reflects a provider’s dedication to sustainable practices. These certifications not only enhance credibility but also ensure that your project aligns with global standards.

By prioritizing quality control processes and certifications, you can select a PCB assembly partner capable of delivering dependable results. These factors safeguard your project from defects, delays, and compliance issues, ensuring a smooth path to success.

Understanding Technical Capabilities and Services Offered by PCB Assembly Providers

Selecting a PCB assembly provider with the right technical capabilities ensures your project’s success. Providers with advanced tools and a comprehensive range of services can meet your unique requirements while maintaining high-quality standards. By understanding their offerings, you can make an informed decision that aligns with your project goals.

Range of Services

A reliable PCB assembly provider offers a wide range of services to support your project from start to finish. These services often go beyond basic assembly, providing you with a complete solution tailored to your needs. Here are some key services to look for:

- PCB Design Assistance: Some providers help refine your PCB design to optimize manufacturability and performance. This service reduces errors and ensures a smoother production process.

- Component Sourcing: Trusted providers manage the procurement of high-quality components, saving you time and ensuring compatibility with your design.

- Testing and Inspection: Comprehensive testing, such as functional testing and in-circuit testing, ensures your PCB operates reliably before it reaches the market.

Additionally, many providers specialize in different types of PCB assembly, including:

- Through-Hole Assembly: Ideal for projects requiring strong mechanical bonds and durability.

- Surface Mount Assembly (SMT): Suitable for compact designs with high component density.

- Mixed Technology Assembly: Combines through-hole and SMT techniques for projects with diverse requirements.

Providers like PCBWay offer turn-key solutions, handling everything from component sourcing to final shipment. This level of service simplifies your supply chain and ensures consistent quality throughout the process.

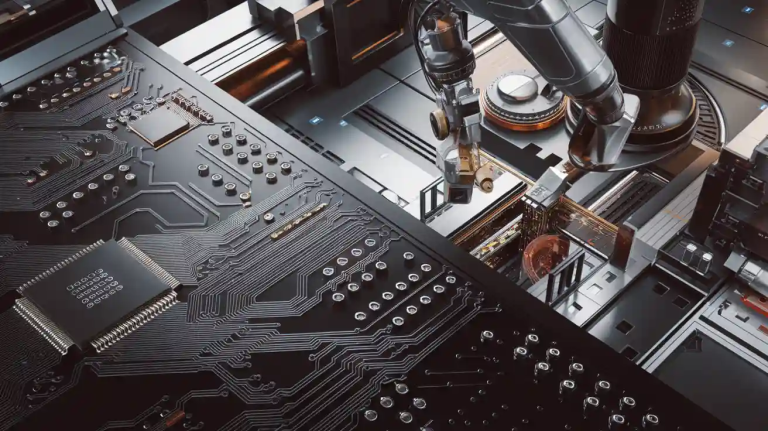

Equipment and Technology

The equipment and technology used by a PCB assembly provider directly impact the quality and efficiency of your project. Advanced machinery ensures precision, reduces errors, and speeds up production. When evaluating a provider, consider their technological capabilities, such as:

- Automated Assembly Machines: These machines enhance accuracy and consistency, especially for high-density boards.

- High-Density Interconnect (HDI) Technology: This technology supports complex designs with multiple layers, enabling compact and efficient PCBs.

- Inspection Tools: State-of-the-art inspection systems, like automated optical inspection (AOI) and X-ray inspection, detect defects early and ensure compliance with your specifications.

For example, providers like PCBWay utilize cutting-edge equipment to manufacture PCBs with up to 14 layers and perform 100% electrical testing. This ensures that every board meets stringent quality standards.

By choosing a provider with a robust range of services and advanced technology, you can streamline your project and achieve superior results. These factors not only enhance the reliability of your PCB but also contribute to the overall success of your product.

Balancing Cost and Value in PCB Assembly Services

Balancing cost and value is a critical step when selecting a PCB assembly partner. While cost often influences decisions, focusing solely on price can lead to compromises in quality and service. A thorough evaluation of pricing structures and the value-added services offered by providers ensures you make a choice that aligns with your project goals.

Transparent Pricing

Transparent pricing helps you understand the true cost of PCB assembly services. Reliable providers offer clear breakdowns of their pricing structures, allowing you to identify potential hidden fees. These costs may include assembly charges, component procurement fees, or additional testing expenses. By reviewing these details, you can avoid unexpected expenses that disrupt your budget.

When comparing providers, request detailed quotes that outline all costs. Look for clarity in areas such as:

- Assembly Fees: Ensure the provider specifies the cost of assembling your PCB, including labor and equipment usage.

- Component Sourcing: Some providers charge premiums for sourcing components. Verify if their rates are competitive and if they source from trusted suppliers.

- Testing and Inspection: Comprehensive testing often incurs additional costs. Confirm whether these services are included in the quote or billed separately.

Transparent pricing not only builds trust but also helps you plan your project finances effectively. A provider with straightforward pricing practices demonstrates professionalism and a commitment to customer satisfaction.

Value for Money

Value for money goes beyond the initial cost of services. It reflects the overall benefits you receive in exchange for your investment. A provider offering competitive pricing without compromising on quality delivers greater value for your project.

To assess value, consider the following factors:

- Quality Assurance: Providers with robust quality control processes ensure reliable outcomes. High-quality PCBs reduce the risk of defects and rework, saving you time and resources.

- Turnaround Time: Timely delivery impacts your supply chain efficiency. A provider with a proven track record of meeting deadlines adds significant value to your operations.

- Support Services: Value-added services, such as design assistance or technical support, enhance the overall experience. These services streamline the production process and address potential challenges proactively.

For example, a provider may charge slightly higher assembly fees but include comprehensive testing and faster delivery. This approach minimizes delays and ensures your product reaches the market on time. By analyzing the cost versus the value offered, you can select a partner who contributes to your project’s success.

Balancing cost and value requires careful consideration of both pricing transparency and the benefits provided. A well-informed decision ensures you achieve high-quality results without exceeding your budget.

Reviewing Customer Support and Communication in PCB Assembly

Effective customer support and clear communication are essential when selecting a PCB assembly partner. These factors ensure smooth collaboration, quick resolution of issues, and a seamless project experience. By evaluating responsiveness and problem-solving capabilities, you can identify a provider that prioritizes your needs and contributes to your project’s success.

Responsiveness

Responsiveness reflects how quickly and effectively a provider addresses your inquiries and concerns. A responsive partner minimizes delays and keeps your project on track. When assessing responsiveness, consider the following:

- Speed of Replies: Evaluate how quickly the provider responds to emails, calls, or messages. Prompt replies indicate a commitment to customer satisfaction.

- Helpfulness and Knowledge: Interactions with customer service representatives should leave you confident in their expertise. Representatives must provide clear and accurate answers to your questions.

- Availability: Reliable providers offer multiple communication channels, such as phone, email, and live chat, ensuring you can reach them when needed.

You can gauge responsiveness by contacting the provider directly or reviewing feedback from other customers. For example, online reviews often highlight the speed and quality of customer service. A provider with consistently positive feedback demonstrates reliability and attentiveness.

“Assessing the speed, helpfulness, politeness, and knowledge of customer service representatives provides valuable insights into service quality.” – Industry Expert

Collaboration and Problem-Solving

Collaboration and problem-solving skills are critical for overcoming challenges during the PCB assembly process. A strong partner works with you to address issues proactively and ensures your project progresses smoothly. Key aspects to evaluate include:

- Willingness to Collaborate: The provider should involve you in decision-making and keep you informed about project updates. Open communication fosters trust and ensures alignment with your goals.

- Problem-Solving Approach: Assess how the provider handles unexpected challenges. Do they offer practical solutions and take responsibility for resolving issues? A proactive approach minimizes disruptions and maintains project momentum.

- Customer Testimonials: Online testimonials and reviews often reveal how well a provider collaborates with clients. Look for feedback that highlights their ability to solve problems effectively and maintain strong communication.

For instance, a provider that actively seeks your input during design revisions or promptly resolves component shortages demonstrates a customer-focused mindset. This level of collaboration ensures your project stays on schedule and meets quality expectations.

By prioritizing responsiveness and collaboration, you can select a PCB assembly partner that values your input and delivers exceptional service. These qualities enhance the overall experience and contribute to the success of your project.

Considering Location and Logistics for PCB Assembly

When selecting a PCB assembly partner, location and logistics play a crucial role in ensuring smooth operations and timely delivery. Evaluating these factors helps you minimize delays, reduce costs, and maintain control over your project.

Proximity to Your Business

Proximity to your business offers several advantages that can streamline your project. A nearby PCB assembly provider allows for faster communication and easier collaboration. You can visit their facility to inspect processes, discuss requirements, or address concerns in person. This hands-on approach ensures better alignment with your expectations.

Local providers also reduce shipping times and costs. Shorter transit distances mean quicker delivery of assembled PCBs, which is especially beneficial for time-sensitive projects. Additionally, working with a nearby partner minimizes the risk of damage during transportation, ensuring your boards arrive in optimal condition.

If your project requires frequent updates or adjustments, proximity becomes even more critical. A local partner can respond to changes more quickly, helping you stay on schedule and avoid disruptions.

Supply Chain Efficiency

Efficient supply chain management is essential for successful PCB assembly. A reliable provider ensures that components are sourced, assembled, and delivered without unnecessary delays. When evaluating a partner, consider their ability to manage logistics effectively.

Providers with established relationships with trusted suppliers can secure high-quality components at competitive prices. This reduces the risk of counterfeit or substandard parts entering your project. Additionally, a well-organized supply chain ensures that materials are available when needed, preventing production bottlenecks.

Assess the provider’s shipping and delivery capabilities. A partner with robust logistics infrastructure can handle large orders and meet tight deadlines. Look for features like real-time tracking and flexible shipping options, which enhance transparency and reliability.

Global projects may require international shipping. In such cases, choose a provider experienced in handling customs regulations and international logistics. Their expertise ensures smooth cross-border operations and prevents unexpected delays.

By prioritizing proximity and supply chain efficiency, you can select a PCB assembly partner that supports your project’s success. These factors not only improve operational efficiency but also contribute to better outcomes for your business.

Selecting the right PCB assembly partner is a critical step in ensuring your project’s success. By evaluating factors such as experience, quality assurance, technical capabilities, cost, customer support, and logistics, you can make an informed decision that aligns with your specific needs. Thorough research helps you identify a partner who not only meets your requirements but also enhances your supply chain efficiency. Building a strong partnership with a reliable provider ensures consistent quality, timely delivery, and long-term success in the fast-paced electronics industry.