Selecting the right PCB manufacturing and assembly service provider is crucial for ensuring the reliability and performance of your printed circuit boards. A reputable PCB assembly company can deliver high-quality products that meet your specific requirements. Factors like manufacturing capabilities, certifications, and material sourcing play a significant role in determining the quality of the final product. Additionally, aspects such as cost, turnaround time, and customer support directly impact customer satisfaction and the overall value of the service. By prioritizing these elements, you can partner with a provider that guarantees reliable PCB assembly and long-term success.

Key Takeaways

- Pick a PCB maker that follows quality rules. Check for safety badges like UL Listing and IPC to trust their work.

- Look at how much experience the company has. Pick one with a good history in many fields to fit your needs.

- Check what services they offer. A good company should handle different PCB types and help with design and testing.

- Think about the price and value. Choose a company that offers fair prices and good quality to avoid extra costs later.

- See how they treat customers. A helpful company will keep you updated and fix problems fast, making your experience better.

Ensuring Quality in PCB Manufacturing and Assembly

Importance of Quality Standards

When selecting a PCB manufacturer, you must prioritize quality standards to ensure high-quality products. Standards like the UL Listing are critical as they address safety requirements, including fire and electrical shock risks. Compliance with these standards guarantees customer safety and enhances the reliability of your printed circuit board. Additionally, the MIL-STD serves as a benchmark for performance and environmental requirements, which many manufacturers voluntarily adopt to meet high standards of quality.

PCB assembly services often classify products into three categories based on quality requirements:

| Class | Description | Testing Requirements |

|---|---|---|

| 1 | General Electronics Products | Lower testing standards, allowing minor imperfections. |

| 2 | Dedicated Service Electronic Products | Stricter testing for reliability, minor defects allowed. |

| 3 | High-Reliability Electronic Products | Extensive testing to meet the strictest quality standards. |

By understanding these classifications, you can align your needs with the appropriate service provider.

Certifications and Compliance

Certifications play a vital role in ensuring quality and standards compliance. A reputable PCB assembly company will hold certifications such as IPC, ISO, and RoHS. IPC defines industry-accepted practices for PCB assembly services, while ISO focuses on quality management and customer satisfaction. RoHS certification ensures the reduction of hazardous materials, promoting environmental safety. Other certifications like UL Listing and ITAR demonstrate a commitment to safety and the protection of sensitive technologies. These certifications reflect the reputation and reliability of the service provider, ensuring you receive high-quality products.

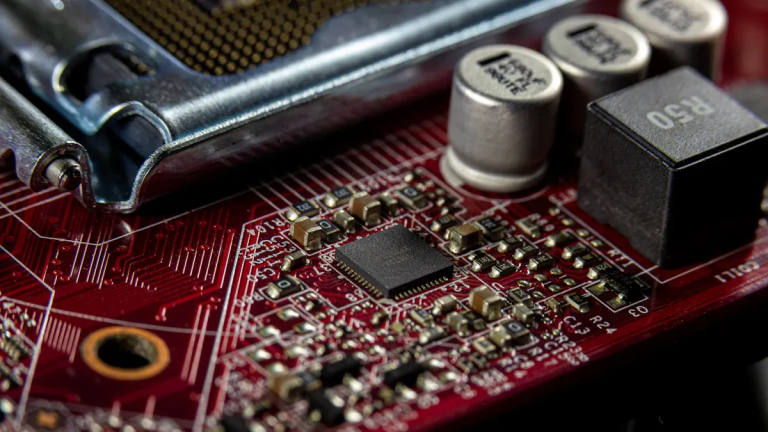

Testing and Inspection Processes

Effective testing and inspection processes are essential for quality assurance in PCB manufacturing and assembly. Leading service providers implement multiple inspection techniques to identify defects early. For bare PCBs, methods like visual inspection, flying probe testing, and automated optical inspection are common. For assembled PCBs, advanced techniques such as solder paste inspection, x-ray imaging, and in-circuit testing ensure precision and reliability.

A comprehensive testing process typically includes:

- Material Inspection: Verifying raw materials for defects.

- Automated Optical Inspection (AOI): Scanning for visual defects using high-resolution cameras.

- Electrical Testing: Checking connectivity between layers and components.

- X-Ray Inspection: Detecting internal defects in multilayer PCBs.

- Environmental Testing: Conducting thermal shock and humidity tests.

By partnering with a service provider that prioritizes quality control, you can ensure your printed circuit boards meet the highest standards of quality and reliability.

Evaluating Experience and Expertise

Industry Experience and Track Record

When choosing a PCB manufacturer, their industry experience and track record should be a top priority. A service provider with years of experience demonstrates a proven ability to handle complex projects and deliver consistent results. You should look for companies that have worked across diverse industries, such as automotive, aerospace, and consumer electronics. This breadth of experience ensures they can meet your specific requirements with precision and reliability.

A strong track record also reflects the provider’s commitment to quality and customer satisfaction. You can evaluate this by reviewing case studies, client testimonials, or industry awards. These indicators highlight their ability to deliver high-quality PCB assembly services while maintaining reliability over time.

Advanced Technologies and Adaptability

The PCB manufacturing and assembly industry is evolving rapidly, and advanced technologies are shaping its future. A service provider that adopts cutting-edge innovations can offer you better quality assurance and efficiency. Some of the key technologies transforming the industry include:

- Advanced materials like polymers and nanomaterials for improved performance.

- Additive manufacturing (3D printing) for complex designs and reduced waste.

- High Density Interconnect (HDI) technology for miniaturized devices.

- Flexible and stretchable PCBs for wearable electronics.

- Automated manufacturing using AI and robotics for consistent quality.

- Embedded components to enhance PCB density and performance.

You should also consider providers that integrate IoT devices for real-time monitoring or use AI and machine learning to optimize production. These technologies demonstrate adaptability and ensure your PCB assembly service provider stays ahead of industry trends.

Skilled Workforce and Technical Knowledge

A skilled workforce is the backbone of any reliable PCB assembly company. Technicians and engineers with deep technical knowledge ensure that every step of the manufacturing process meets the highest standards. You should assess whether the provider invests in continuous training and development for their team. This commitment to skill enhancement reflects their dedication to delivering quality products.

Additionally, a knowledgeable team can address challenges like component misplacement or design flaws with precision. Their expertise ensures that your PCB assembly services are efficient and error-free, saving you time and costs in the long run.

Tip: Always ask about the qualifications and certifications of the workforce to gauge their expertise and reliability.

Assessing Capabilities and PCB Assembly Services

Range of Services Offered

A comprehensive PCB assembly service provider should offer a wide range of services to meet diverse project requirements. You should look for providers capable of handling various PCB types, including:

- Single-layer PCBs

- Multi-layer PCBs

- Rigid, flex, and rigid-flex PCBs

- High-density interconnect (HDI) boards and special materials

Beyond manufacturing, the best providers also support additional services that streamline your project. These include PCB design assistance to optimize layouts for functionality, component sourcing to ensure efficient procurement, and thorough testing and inspection to guarantee quality. By choosing a provider with such capabilities, you can ensure your project runs smoothly from start to finish.

Advanced Equipment and Technology

The use of advanced equipment significantly enhances the efficiency and accuracy of PCB assembly processes. Modern PCB manufacturers rely on state-of-the-art machinery for precise component placement, intricate soldering, and comprehensive testing. This ensures high-quality outcomes at every stage of production. The growing demand for automation in the industry highlights the importance of such technology. For example, the global PCB manufacturing equipment market is projected to reach USD 7.9 billion by 2030, reflecting the increasing complexity of modern electronic devices. By partnering with a service provider that invests in advanced equipment, you can achieve superior quality and reliability in your products.

Customization and Turnkey PCB Assembly Options

Turnkey PCB assembly services provide a seamless solution for businesses by managing the entire production process. These services offer numerous benefits, including superior quality assurance, early detection of issues, and significant time savings. With turnkey solutions, you can focus on your core operations while relying on a single contact point for all assembly needs. This simplifies adjustments and enhances overall efficiency.

| Benefit | Description |

|---|---|

| Integrated Efficiency | Streamlines the entire PCB production process, from design to final assembly. |

| Cost-Effectiveness | Often leads to significant long-term savings despite higher initial costs. |

| Quality Assurance | Higher quality products due to consistent standards and comprehensive testing. |

| Time Savings | Faster turnaround times help meet tight market deadlines. |

| Scalability | Easily adjusts to changing production needs, from prototypes to high-volume runs. |

Customization options further enhance the value of turnkey services. Whether you need tailored designs or specific material requirements, a capable PCB assembly company can adapt to your unique needs. This flexibility ensures your products meet exact specifications while maintaining high standards of quality and reliability.

Balancing Cost and Value

Cost-to-Value Ratio

When selecting a PCB assembly service provider, understanding the cost-to-value ratio is essential. A low-cost option may seem appealing initially, but it often sacrifices quality and reliability. Instead, focus on providers that balance competitive pricing with exceptional quality assurance. This ensures you receive durable and high-performing products without overspending.

Turnkey PCB assembly services often provide the best cost-to-value ratio. These services streamline the entire process, from design to final assembly, reducing the need for multiple vendors. By consolidating tasks, you save time and minimize errors, which translates to better value for your investment. Additionally, providers with advanced capabilities and expertise can optimize your designs for manufacturability, further enhancing cost efficiency.

Avoiding Hidden Costs

Hidden costs in PCB manufacturing and assembly can significantly impact your budget. To avoid these, you must carefully evaluate the service provider’s processes and design recommendations. Common hidden costs include:

- Placing pads too close to the PCB edge, leading to damage during assembly.

- Ignoring industry-standard tolerances, which may require costly fixtures.

- Adding unnecessary layers to PCB designs, increasing manufacturing expenses.

Collaborating with a PCB assembly company that prioritizes transparency and design optimization can help you avoid these pitfalls. Providers offering turnkey PCB assembly services often include design reviews to identify and eliminate potential cost drivers early in the process. This proactive approach ensures you achieve cost and value for money without compromising quality.

Long-Term Benefits of Reliable Providers

Partnering with a reliable PCB manufacturer offers significant long-term benefits. American PCB manufacturers, for instance, adhere to strict quality standards, ensuring every product meets high levels of reliability. This commitment minimizes defects and enhances product performance, which is crucial for customer satisfaction and brand reputation.

Reliable service providers also optimize efficiency, reducing production downtime and minimizing errors that lead to costly reruns. Their focus on design for manufacturability lowers costs while improving adaptability to market changes. Additionally, domestic production enhances supply chain reliability by reducing shipping issues and enabling quick responses to demand fluctuations. These advantages make a reliable provider an invaluable partner for your business.

Tip: Always evaluate a provider’s track record and capabilities to ensure they align with your long-term goals.

Turnaround Time and Logistics

Delivery Timelines and Efficiency

Delivery timelines play a critical role in the success of your PCB assembly projects. Several factors influence these timelines, including the complexity of the design, material availability, and the manufacturing capacity of the service provider. For instance, intricate designs with multiple layers or high component density often require more time to process. Similarly, shortages of raw materials or delays in sourcing custom components can extend lead times. The manufacturing processes and quality assurance protocols also impact the overall timeline. A service provider with advanced equipment and streamlined processes can significantly reduce production time, ensuring faster delivery.

To manage expectations effectively, you should maintain clear communication with your PCB manufacturer. Discussing capacity and scheduling upfront helps you plan better and avoid unexpected delays. Additionally, efficient logistics planning ensures timely delivery, especially for turnkey PCB assembly services where every step of the process is managed by a single provider.

Workflow Optimization

Optimizing workflow is essential for improving turnaround times in PCB assembly service operations. By maximizing machine utilization and minimizing downtime, manufacturers can enhance production efficiency. For example, reducing changeover times between production runs can save valuable hours each week. This directly impacts the ability to meet tight deadlines without compromising quality.

Collaboration between designers and manufacturers also plays a key role in workflow optimization. When both parties work together to clarify project requirements, it reduces discrepancies and ensures smoother production cycles. Regular communication fosters a culture of continuous improvement, helping to identify and eliminate bottlenecks. These practices are particularly beneficial for turnkey PCB assembly services, where streamlined workflows lead to faster and more reliable outcomes.

Impact of Location on Logistics

The geographic location of your PCB manufacturer significantly affects logistics and delivery efficiency. Local manufacturers often provide quicker turnaround times for nearby customers due to reduced shipping distances. However, they may have higher production costs compared to offshore providers. On the other hand, offshore manufacturers can offer cost savings but may require longer shipping times, which could extend your project timelines.

When selecting a service provider, you should consider the trade-offs between cost and delivery speed. For turnkey PCB assembly projects, the location of the provider becomes even more critical as it impacts the entire supply chain. A well-located provider ensures timely material sourcing, efficient production, and prompt delivery, helping you meet your deadlines without compromising quality.

Importance of Customer Support in PCB Assembly Services

Responsiveness and Communication

Effective customer support begins with responsiveness and clear communication. A reliable service provider should prioritize your needs and address queries promptly. This ensures that any issues are resolved quickly, minimizing downtime and keeping your project on track. During initial interactions, assess the provider’s ability to respond to your concerns with knowledge and courtesy. These traits reflect their commitment to delivering a seamless experience.

Additionally, proactive communication is essential. Regular updates on order status, design changes, or potential delays build trust and keep you informed throughout the process. For instance, a pcb assembly service provider offering 24/7 availability ensures that you can reach out at any time, which is particularly valuable for time-sensitive projects. This level of responsiveness demonstrates their dedication to supporting your success.

| Feature | Description | Importance |

|---|---|---|

| 24/7 Availability | Support available at all hours to address issues promptly. | Minimizes downtime and ensures quick resolutions. |

| Technical Expertise | Knowledgeable staff who understand PCB design intricacies. | Provides accurate solutions tailored to project needs. |

| Proactive Updates | Regular notifications on order status and changes. | Keeps customers informed and builds trust. |

Personalized Support and Solutions

Every project has unique requirements, and a good pcb assembly service provider tailors their support to meet your specific needs. Generic solutions often fail to address the complexities of modern PCB designs. Instead, look for providers that offer flexibility in their services, such as customized assembly processes or testing routines. This adaptability ensures that your project receives the attention it deserves.

For example, turnkey pcb assembly services often include tailored solutions that streamline the entire production process. By managing everything from design to final assembly, these providers simplify adjustments and reduce errors. This personalized approach not only enhances quality assurance but also saves you time and resources.

Tip: During your evaluation, inquire about the provider’s ability to customize their services. This will help you determine if they can handle your project’s unique challenges effectively.

Post-Sales Assistance and Reliability

Post-sales support is a critical aspect of customer service. A dependable pcb manufacturer provides robust assistance to resolve issues quickly and prevent future problems. Services like troubleshooting, repairs, and functional testing ensure that your products perform as expected. For instance, advanced testing methods such as Automated Optical Inspection (AOI) and X-ray testing help identify and address defects efficiently.

Reliable post-sales support also includes ongoing communication to address any concerns that may arise after delivery. This commitment to quality and customer satisfaction strengthens your partnership with the service provider. By choosing a pcb assembly service that excels in post-sales reliability, you can ensure long-term success for your projects.

Note: Providers offering turnkey pcb assembly services often include comprehensive post-sales support, making them an excellent choice for businesses seeking end-to-end solutions.

Additional Considerations for PCB Assembly Companies

Material Sourcing and Compliance

Material sourcing plays a critical role in ensuring consistent performance and reliability in PCB assembly. You should prioritize working with a service provider that sources materials from trusted suppliers. This ensures the quality of the raw materials used in your PCBs. For instance, selecting suppliers that provide UL-approved circuit boards guarantees adherence to safety and performance standards. Additionally, compliance with regulations such as RoHS and REACH is essential for meeting environmental and safety requirements.

Ethical sourcing is another important consideration. Awareness of conflict materials in the supply chain promotes transparency and aligns with global ethical standards. By choosing a PCB manufacturer that values compliance and ethical practices, you can ensure your products meet both regulatory and moral expectations.

Optional Services for Enhanced Performance

Optional services can significantly enhance the performance and durability of your PCB assemblies. Functional testing services, for example, verify that each board operates flawlessly under real-world conditions. This ensures reliability and minimizes the risk of defects. Advanced inline aqueous cleaning services remove contaminants, providing cleaner boards that perform better over time.

For complex assemblies, expert BGA rework and reballing services ensure reliable connections and long-term functionality. Precision AOI and visual inspection services detect defects early, maintaining top-tier quality control. Efficient materials procurement and kitting streamline the assembly process, keeping production on schedule. By leveraging these optional services, you can optimize your PCB assembly service for superior results.

Testing Options for Quality Assurance

Testing is a cornerstone of quality assurance in PCB manufacturing. A reliable service provider employs rigorous testing methods to minimize defects and ensure performance standards are met. Common testing options include material inspection, automated optical inspection (AOI), and electrical testing. These methods identify issues early, reducing the likelihood of costly rework.

Additional testing options include:

- Lamination Testing: Ensures the durability and functionality of the PCB layers.

- Copper Plating Assessment: Verifies conductivity for optimal performance.

- Solderability Testing: Confirms components attach securely to the board.

- Environmental Testing: Measures water absorption and performance under humid conditions.

Advanced techniques like in-circuit testing (ICT) and flying probe testing detect faults with high accuracy. X-ray inspection is particularly useful for multilayer PCBs, identifying internal defects that other methods might miss. By selecting a service provider with comprehensive testing capabilities, you can ensure the quality and reliability of your PCB assemblies.

Selecting the right PCB manufacturer is essential for achieving reliable and high-performing products. Key factors to consider include lead time, customer service, pricing, and manufacturing capabilities. You should also evaluate certifications, material sourcing, and the provider’s ability to meet your specific requirements. Balancing cost and value is crucial—prioritize quality over the lowest price to avoid future issues.

To make an informed decision, consult trusted providers and request detailed quotes. These quotes help you understand all associated costs and compare options effectively. Additionally, customer feedback can offer valuable insights into the reliability and support of a PCB assembly company. By focusing on these aspects, you can partner with a service provider that ensures long-term success for your projects.

FAQ

What is the most important factor when choosing a PCB manufacturer?

You should prioritize quality above all else. Look for certifications like ISO and IPC, as they ensure adherence to industry standards. A reliable PCB manufacturer will also have a proven track record, advanced equipment, and robust testing processes to deliver high-quality products.

How can you ensure the reliability of a PCB assembly service?

Evaluate the provider’s testing methods, such as automated optical inspection and x-ray testing. These processes detect defects early and ensure precision. Additionally, check for certifications and customer reviews to confirm their commitment to quality and reliability.

What are turnkey PCB assembly services?

Turnkey PCB assembly services handle the entire production process, from design to final assembly. They streamline operations, reduce errors, and save time. This option is ideal if you want a single point of contact for all your PCB manufacturing and assembly needs.

How do advanced technologies improve PCB assembly?

Advanced technologies, like automated manufacturing and high-density interconnects, enhance precision and efficiency. They reduce errors, improve quality, and support complex designs. Choosing a provider that invests in these technologies ensures your PCBs meet modern performance standards.

Why is customer support crucial in PCB assembly services?

Customer support ensures smooth communication and quick resolution of issues. A responsive provider keeps you informed about project updates and addresses concerns promptly. This level of service minimizes delays and enhances your overall experience.