Metal Core PCB

- Home

- Metal Core PCB

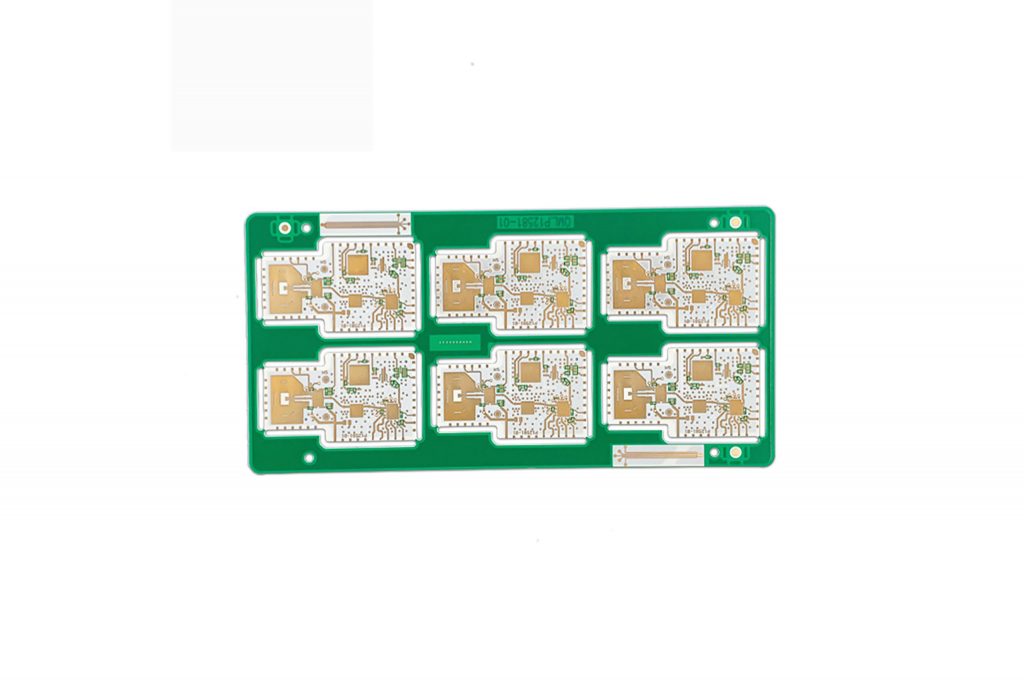

Metal Core PCB Services

Why Choose Us

Specialized Metal-Based PCB Manufacturing:

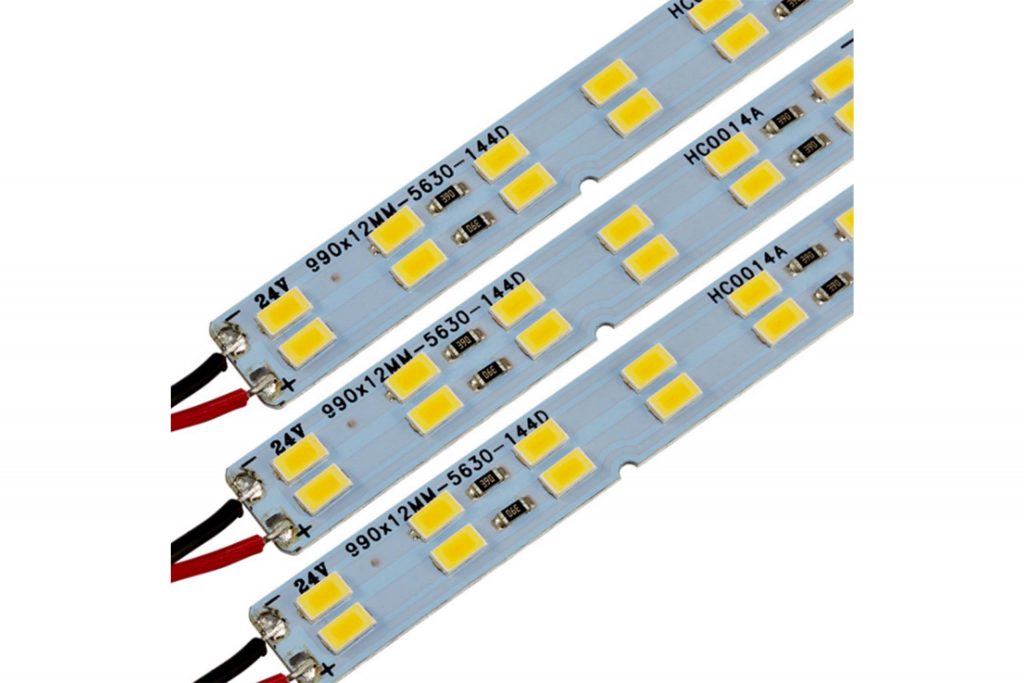

Our company specializes in the production of high thermal conductivity metal-based PCBs, leveraging advanced manufacturing techniques to ensure superior quality. These PCBs are designed to efficiently transfer heat away from critical components, making them ideal for applications such as LED lighting, power electronics, and automotive systems. With our expertise, we deliver reliable and effective solutions tailored to the specific thermal management needs of our clients.

Advanced Thermal Management Technology:

We utilize cutting-edge thermal management technology in our metal-based PCBs to enhance heat dissipation performance. This ensures that electronic components can operate at optimal temperatures, reducing the risk of overheating and improving overall system reliability. Our designs integrate innovative thermal pathways that maximize heat transfer, providing robust solutions for industries where thermal performance is critical.

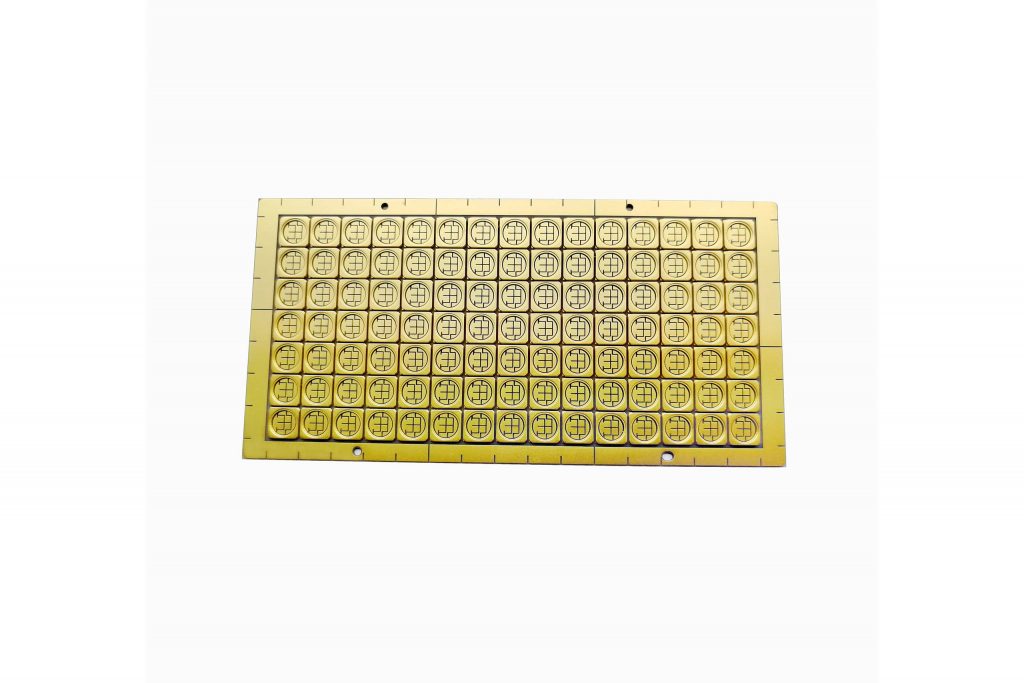

Multiple Material Options:

To accommodate a wide range of applications, we offer a variety of metal substrate options, including aluminum, copper, and other specialized materials. Each material is chosen based on its thermal and electrical properties, allowing us to provide customized solutions that meet specific operational requirements. This flexibility enables us to serve diverse sectors such as consumer electronics, telecommunications, and industrial applications, ensuring that our clients receive the best material for their unique needs.

High Strength and Durability:

Our manufacturing processes adhere to strict quality control standards, ensuring that our metal-based PCBs exhibit high strength and durability. We conduct rigorous testing at each production stage to confirm that our products can withstand demanding conditions and extended use. This commitment to quality means that our clients can rely on our PCBs for long-term performance, even in challenging environments, reducing maintenance and replacement costs.

production capacity

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 4 – 24layers |

| Order Quantity | 1pc – 10000+pcs |

| Material | Aluminum core (Domestic 1060), Copper core, FR4 covering |

| Board Size | Min 6*6mm | Max 610*610mm |

| Board Thickness | 0.8mm – 5.0mm |

| Copper Weight (Finished) | 0.5oz – 10.0oz |

| Min Tracing/Spacing | 4mil/4mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | * HASL – Hot Air Solder Leveling * Lead Free HASL – RoHS * ENIG – Electroless Nickle * Immersion Gold – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

| Other Techniques | * Countersink holes * Screw holes |

PCB Factory Display

Frequently Asked Questions

The most important benefit of metal core printed circuit board is its ability to dissipate heat. With components that aren’t overheated, performance is optimized.

We are equipped to offer Aluminum, Copper, Steel, Stainless steel, and Iron Alloy as base material.

Yes, we are fully equipped to provide metal core PCB prototypes, as also large production runs.

Totally. Share your requirements with us and our PCB experts can help you with your needs.

Most certainly! We offer quick lead time, so you have a huge competitive advantage.