Rigid-Flex PCB

- Home

- Rigid-Fkex PCB

Rigid-Fkex PCB

- Home

- Rigid-Fkex PCB

Advantages of Rigid-Flex PCB Production

Why Choose Us

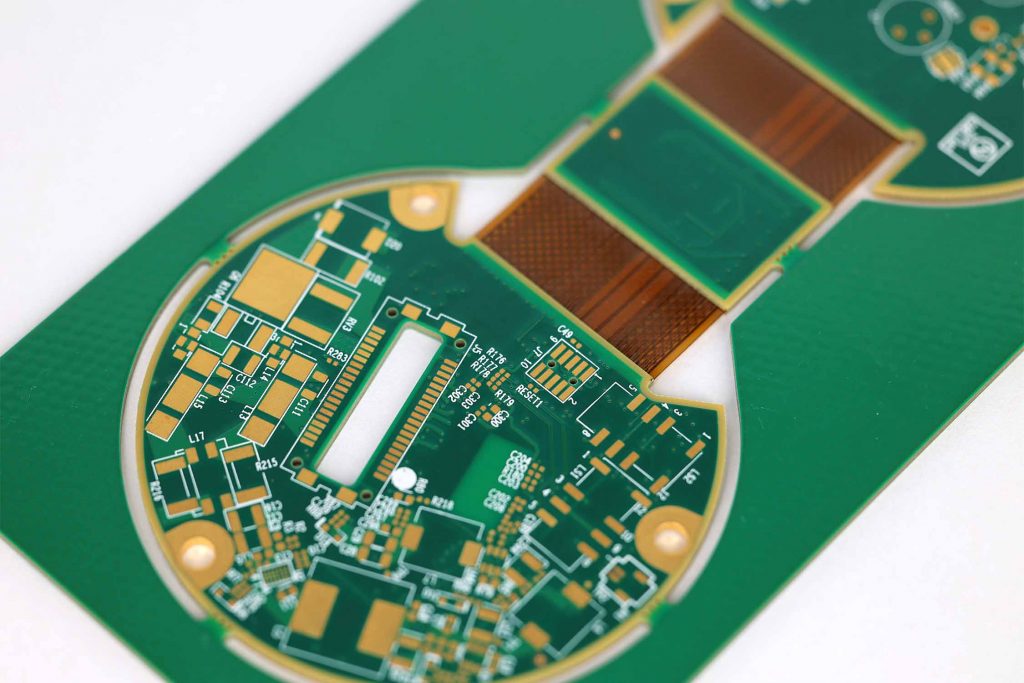

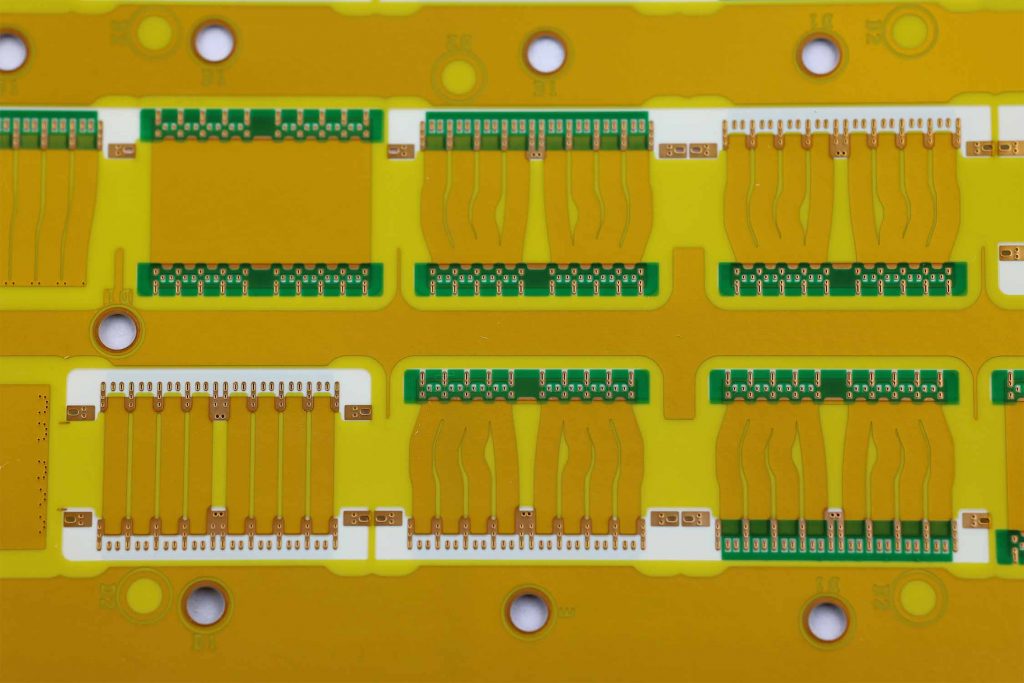

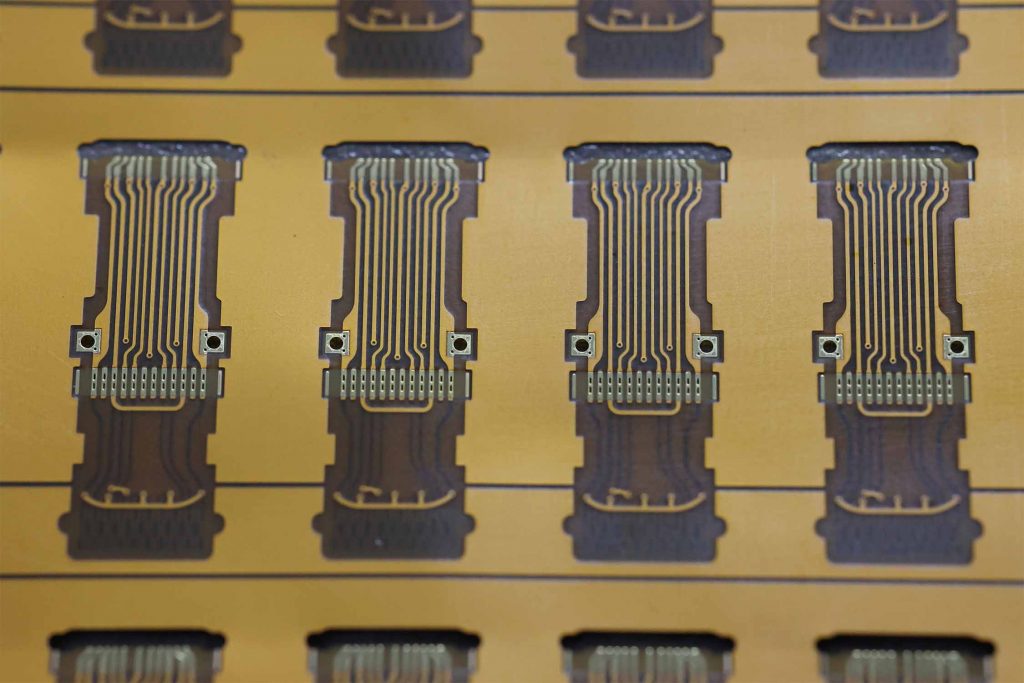

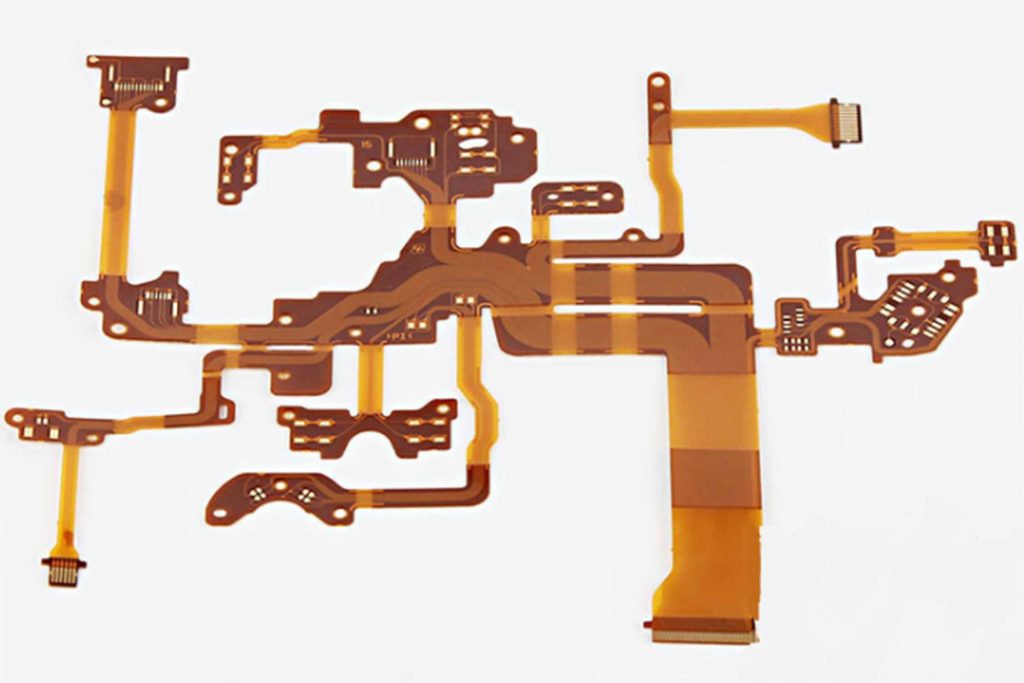

Expert Rigid-Flex PCB Manufacturing

We specialize in producing high-quality rigid-flex PCBs, leveraging extensive experience and advanced equipment. Our rigid-flex PCBs are not only structurally reliable but also provide excellent electrical performance, making them ideal for compact and complex electronic devices requiring high stability and precision.

Support for Complex Designs

We offer multilayer, high-density rigid-flex PCBs that meet the needs of complex circuit designs and stringent space constraints. Whether for industrial control systems, medical devices, or consumer electronics, our products cater to demands for miniaturization, high performance, and flexible connections, with exceptional design and engineering support.

Flexible Customization

To meet the diverse needs of our clients, we provide flexible customization services. From material selection and thickness configuration to specialized functional designs, we tailor rigid-flex PCB solutions according to specific application requirements, ensuring optimal performance in various use cases.

High Reliability and Durability

Every step of our rigid-flex PCB manufacturing process undergoes strict quality control to ensure high reliability and durability. Rigorously tested and inspected, our products perform consistently even under high stress and harsh environments, making them suitable for demanding industries such as aerospace, automotive electronics, and high-end consumer electronics.

production capacity

Items | Rigid |

Material | Lead-free、Halogen-free、H-Tg、Low loss |

Layers | 1-40L |

Max cut lamination size | Min3*3mm-Max1200mm |

Final board thickness | 0.18-5.0mm |

Min Final Hole size | 0.075mm |

Aspect Ratio | 14:1 |

Inner layer Line Width/Space | 0.05mm |

Copper Foil Thickness (Inner Layers) | 1/2oz~3.0oz |

Min dielectric layer thickness | 50um |

Copper Foil Thickness (Outer Layers) | Hoz-14oz |

Copper to drill distance | 0.2mm |

Out layer Line width/space | 0.05mm |

Min SMD width | 0.05mm |

Max Solder Mask Plug Hole Diameter | 0.5mm |

solder mask strip width | 0.075mm(Green/1OZ) |

Final Set Size Tolerance | ±0.1mm/limit±0.05mm |

Min Hole to board edge Distance | 0.15mm |

Min Beveling angle Tolerance | ±3-5° |

Layer to layer Tolerance | ≤0.075mm(1-6L) |

Inner layer Min PTH Annular Ring | 0.15mm |

Out layer Min PTH Annular ring | 0.15mm |

Surface Treatment | OSP、HASL 、ENIG、Gold Finger、Plating Gold 、ENEPIG、IMM TIN、IMM AG |

Warp&Twist | ≤0.5% |

PCB factory display

Frequently Asked Questions

Yes, as per the client requirements, we are well equipped to offer first article inspection for through hole PCBs.

DIP (Dual In-line Package) and THT (Through-Hole Technology) are both important terms in the field of electronic component packaging and PCB assembly.

DIP, also known as Dual In-line Package or DIL Package, refers to a specific type of electronic component packaging that features two parallel rows of pins or leads extending from the bottom of the package. DIP package is widely used in electronic assemblies due to their compact size and ease of insertion into PCBs.

THT, on the other hand, stands for Through-Hole Technology. It refers to the manufacturing process that involves drilling holes on a PCB and inserting component leads or pins through these holes. The components are then soldered on the opposite side of the PCB to establish electrical connections.

While DIP is commonly associated with the type of component package used in PCB assembly, THT is the manufacturing process that involves the insertion and soldering of components through holes.

SMT is a widely adopted electronic assembly technology that utilizes SMD components and automated placement machines for the assembly process. This technology offers several advantages, including enhanced processing efficiency and reduced form factor of electronic applications.

On the other hand, THT is more challenging to automate and involves the use of larger components. THT offers the advantage of providing a stronger and more robust connection due to the through-hole soldering technique. It is particularly suitable for components that require additional mechanical support or for applications where durability and reliability are critical.

Well, whether to select through hole PCB assembly or SMT PCB assembly; it totally depends on your requirements. Most of the integrated circuits go for SMT package. However, for connectors, switches, or mechanical power parts, the standard way is to use through hole parts.