KING FIELD ELECTRONIC CO., LTD

PCB/PCBA One-Stop Service Manufacturer

PCB/PCBA One-Stop Service Manufacturer

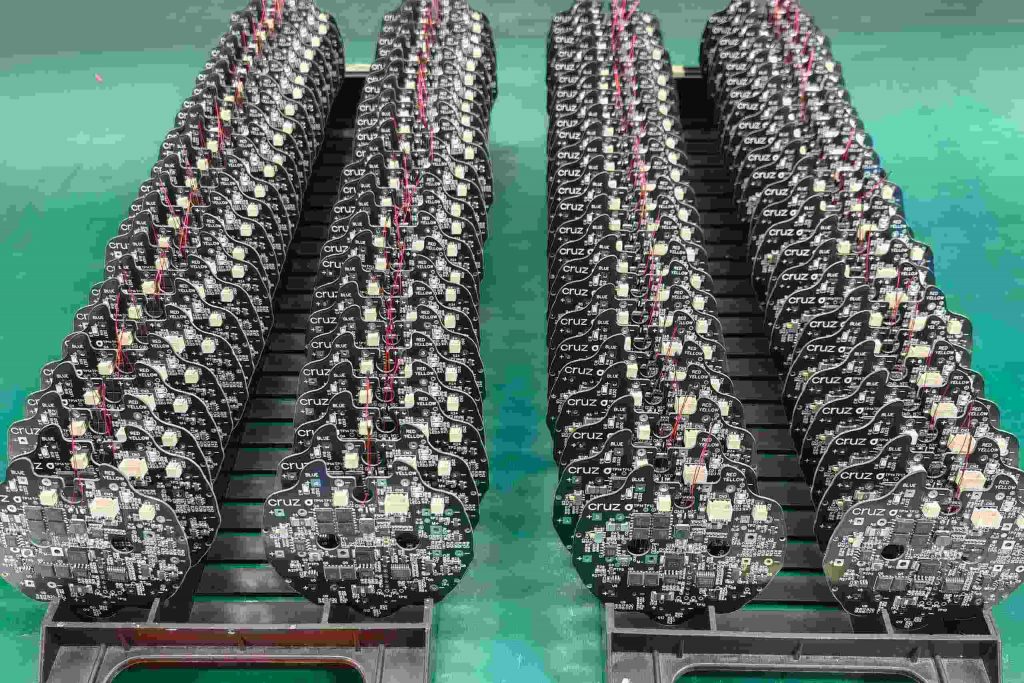

Our factory utilizes advanced SMT technology and is equipped with high-precision placement equipment that can accurately position various components on PCBs. This technology not only ensures the correct placement and orientation of components but also significantly reduces the defect rate caused by human error. We are committed to providing high-quality products, ensuring that every detail meets or exceeds industry standards, thereby enhancing our customers' product performance and reliability.

To meet the market's demand for rapid delivery, we have implemented efficient automated production processes. Our production lines can quickly adapt to different order requirements, ensuring that customers receive their needed products in a short time frame. By optimizing production techniques and increasing operational efficiency, we have significantly shortened lead times, enabling our customers to stay ahead in a competitive market.

We support both small-batch and large-scale production to cater to the diverse needs of our clients. Whether it's for prototype development, pilot runs, or mass production, we can swiftly adjust our production schedules to ensure timely delivery. Our flexibility extends not only to production volume but also to our responsiveness to specific customer requirements, allowing us to quickly adapt and provide tailored solutions based on changing demands.

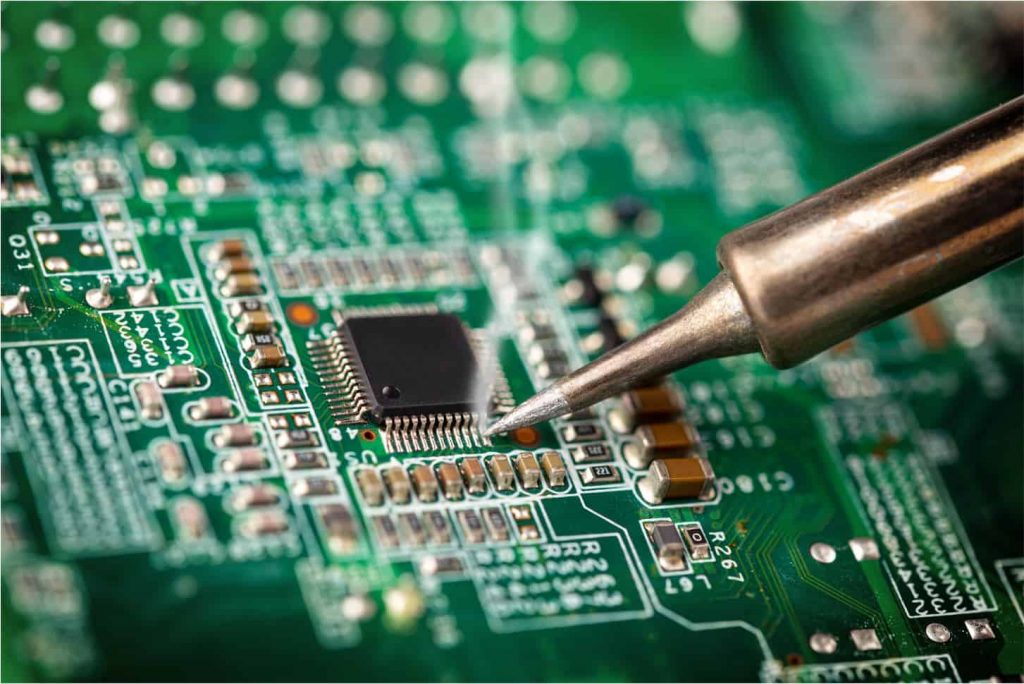

We implement strict quality control measures throughout the production process to ensure that every assembly meets high standards. Our quality control team conducts comprehensive inspections for each batch of products, including functional testing, visual checks, and performance evaluations, to ensure reliability and consistency. We are dedicated to delivering the best products to our customers and continually improving our quality management systems to enhance product quality, earning customer trust and satisfaction.

| Assembly Types | ● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

| Quality Inspection | ● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB |

| Component Types | ● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

| Components Sourcing | ● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste |

| Order quantity | ● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready |

SMT (Surface Mount Technology) assembly refers to the process of using surface mount technology to place electronic components (such as resistors, capacitors, integrated circuits, etc.) directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology (THT), SMT allows components to be mounted directly onto the PCB surface without the need for drilling holes, making it suitable for high-density, miniaturized electronic products.

We are dedicated to manufacturing the highest quality products, whether your needs involve small or high volume SMT PCB assembly production. Through our extensive experience and continuous improvement initiatives, we ensure excellence in every project. Surface Mount Technology (SMT) is the leading and flexible assembly process used to manufacture modern, faster, and more efficient consumer electronics, telecommunications equipment, medical devices, and industrial control systems. As miniaturization becomes increasingly crucial, the significance of SMT technology continues to rise. Our surface mount PCB assembly services guarantee optimal performance and cost-effectiveness, utilizing surface mount devices (SMD) to meet industry standards and exceed customer expectations

Absolutely! With over 20 years of experience in the PCBA industry, KING FIELD has consistently provided high-quality services and established itself as a trusted name in the Chinese PCBA industry. If you are learning about us for the first time, consider checking out our customer reviews!

Unlike other manufacturers, KING FIELD prioritizes service and quality. We do not recommend obtaining PCBA directly through online quotes. Instead, we tailor service projects for our clients after receiving their emails. This approach strengthens our mutual understanding and helps reduce your project costs. If you need an SMT manufacturing quote, simply contact us via email – it’s that simple!

You’ve come to FS Technology, so why not consider trusting us?

If you really don’t need us, you can choose a more suitable SMT PCB assembly supplier based on the following recommendations:

*Compare prices – this goes without saying, the key is to ensure a balance between price and quality, don’t sacrifice one for the other!

*Check if the manufacturer uses advanced equipment – this helps understand the company’s investment in production, reflecting its strength.

*Understand the manufacturer’s production capacity to avoid losses due to production delays caused by limited capacity.

The global manufacturing industry is shifting towards China, and if you need offshore manufacturing, China is a good direction to consider. China SMT assembly services attract customers with a match of quality and price. It is believed that most companies can meet your requirements and consistently adhere to international certification standards!

If your business excels in marketing, then Turnkey PCBA solutions will be your best option. You can focus solely on your strengths, and as for other tasks, KING FIELD will take care of everything for you. For projects that prioritize cost, it is recommended to use a semi-turnkey approach!

Automation is the future mainstream trend, aiding in mass production and avoiding human errors. Therefore, KING FIELD is increasing its investment in equipment, committed to building a digitally intelligent factory to achieve the automation of SMT circuit board assembly.

*Gerber Files

*Bill of Materials

*Component Placement or Pick & Place File

Absolutely! With over 20 years of experience in the PCBA industry, KING FIELD has consistently provided high-quality services and established itself as a trusted name in the Chinese PCBA industry. If you are learning about us for the first time, consider checking out our customer reviews!

Unlike other manufacturers, KING FIELD prioritizes service and quality. We do not recommend obtaining PCBA directly through online quotes. Instead, we tailor service projects for our clients after receiving their emails. This approach strengthens our mutual understanding and helps reduce your project costs. If you need an SMT manufacturing quote, simply contact us via email – it’s that simple!

You’ve come to FS Technology, so why not consider trusting us?

If you really don’t need us, you can choose a more suitable SMT PCB assembly supplier based on the following recommendations:

*Compare prices – this goes without saying, the key is to ensure a balance between price and quality, don’t sacrifice one for the other!

*Check if the manufacturer uses advanced equipment – this helps understand the company’s investment in production, reflecting its strength.

*Understand the manufacturer’s production capacity to avoid losses due to production delays caused by limited capacity.

The global manufacturing industry is shifting towards China, and if you need offshore manufacturing, China is a good direction to consider. China SMT assembly services attract customers with a match of quality and price. It is believed that most companies can meet your requirements and consistently adhere to international certification standards!

If your business excels in marketing, then Turnkey PCBA solutions will be your best option. You can focus solely on your strengths, and as for other tasks, KING FIELD will take care of everything for you. For projects that prioritize cost, it is recommended to use a semi-turnkey approach!

Automation is the future mainstream trend, aiding in mass production and avoiding human errors. Therefore, KING FIELD is increasing its investment in equipment, committed to building a digitally intelligent factory to achieve the automation of SMT circuit board assembly.

*Gerber Files

*Bill of Materials

*Component Placement or Pick & Place File