Methods for disassembling Multi-Pin IC from Circuit Boards

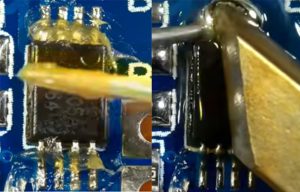

Medical Hollow Needle Disassembly Method

Take 8 to 12 medical hollow needles. When used on a PCB, the inner diameter of the needle just cover the IC pins. During disassembly, melt the solder on the pin by using a soldering iron, then promptly cover the pin with the needle. Rotate the needle as the solder solidifies and pull out the needle. In this way, the pin is completely separated from the PCB. Once all the pins are separated, the IC can be easily removed.

Solder Suction Disassembly Method

Using a solder sucker to remove ICs is a common professional method. The tools that we used include a standard soldering iron with a power of above 35W. When removing the IC, place the heated soldering iron tip on the pins of the IC to be removed. Once the solder on the PCB melts, it is sucked into the solder sucker. When all the solder on the pins has been removed, the IC can be taken off.

Hot Air Gun Heating Method

This method is simple and practical, all you need is a hot air gun and small tweezers. When removing the IC, first heat the hot air gun. Once it reaches the solder melting temperature, aim the hot air gun at the surface of IC and heat it evenly back and forth, heating for about one minute. Then, use tweezers to slowly lift the IC from one corner. This will separate the IC pins from the PCB.

Copper Wire Solder Absorption Method

The copper wire is processed into the shape of an IC pin, and rosin is applied to the copper core. Place the copper wire over the IC pins, heat it with a soldering iron, and add solder to the copper wire. In this way, the solder on the pins will be melted. After repeating this process a few times, slowly pry the IC by using tweezers or a small flat-blade screwdriver to remove it.

Solder Melting Method

This method is convenient. In PCBA OEM assembly, simply add some solder to the IC pins that need to be removed, connecting the solder joints in each row of pins,which is conducive to heat transfer and disassembly. During the removal process, heat each row of pins with a soldering iron, use sharp tweezers or a small “slotted” screwdriver to pry them up, heat the two rows of pins alternately until they are removed. Generally, each row of pins can be removed after heating twice.