PCBA SMT has transformed how you experience modern electronics. By combining printed circuit board assembly with surface mount technology, it enables the creation of smaller, more reliable devices. This innovation ensures that components stay secure, even under mechanical stress, making it ideal for industries like automotive and aerospace. Advanced automated assembly lines further enhance precision, reducing errors and lowering long-term costs. Whether it’s a smartphone or a wearable health monitor, PCBA ensures these devices perform efficiently and consistently.

Key Takeaways

- PCBA SMT joins circuit board assembly with surface mount technology.

- SMT helps fit more parts in less space, making gadgets smaller.

- Devices like phones and wearables become lighter and work better.

- Automated SMT lowers costs and mistakes, improving product quality.

- PCBA SMT makes devices stronger, working well in tough conditions.

- It helps create new products like IoT tools and medical machines.

What is PCBA SMT?

Understanding PCBA

Definition of PCBA

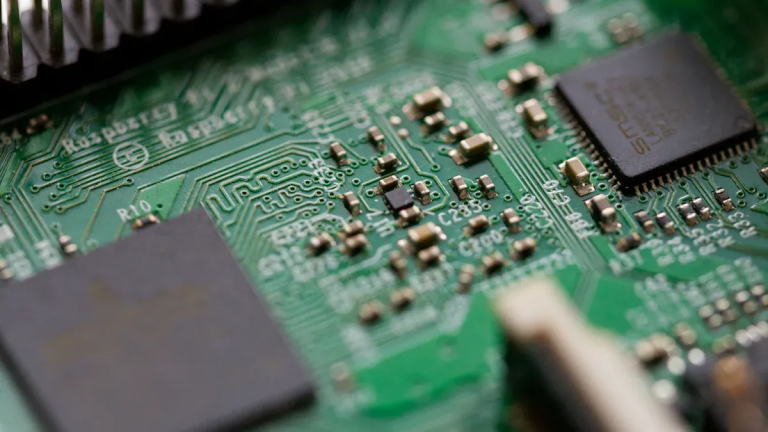

Printed circuit board assembly, or PCBA, refers to the process of assembling electronic components onto a printed circuit board (PCB). This process transforms a bare PCB into a functional electronic circuit. Components like resistors, capacitors, and integrated circuits are mounted onto the board to create a complete system. Without PCBA, modern electronic devices would not function as intended.

Importance of PCBs in Electronics

PCBs serve as the backbone of electronic devices. They provide a platform for connecting components and ensuring electrical signals flow correctly. Whether it’s a smartphone, a laptop, or a medical device, the PCB ensures all parts work together seamlessly. The table below highlights key components of PCBA and their roles in electronics manufacturing:

| Component | Function |

|---|---|

| Resistors | Limit the flow of electrical current within a circuit. |

| Capacitors | Store and release electrical energy. |

| Integrated Circuits (ICs) | Miniaturized electronic circuits consisting of semiconductor devices and passive components. |

| Connectors | Allow the PCBA to connect with other devices or components, enabling the transfer of electrical signals. |

| Diodes | Allow current to flow in one direction only. |

| Transistors | Amplify or switch electronic signals. |

What is Surface Mount Technology?

Definition and Comparison with Through-Hole Technology

Surface mount technology (SMT) is a method where components are mounted directly onto the surface of a PCB. Unlike through-hole technology (THT), which requires drilling holes for component leads, SMT eliminates this step. THT remains relevant for applications needing strong mechanical bonds, such as aerospace and military products. However, SMT dominates modern electronics due to its efficiency and compact design.

| Feature | Surface Mount Technology (SMT) | Through Hole Technology (THT) |

|---|---|---|

| Space Efficiency | Allows for more components in a smaller area | Fewer components can be fit in a given area |

| Assembly Process | Fully automated with machines | Mostly manual or semi-automated |

| Mechanical Bond | Weaker due to surface mounting | Stronger due to leads passing through the board |

| Component Suitability | Suitable for smaller, lightweight components | Best for high-power, bulky components |

| Cost | Higher initial cost but lower overall manufacturing cost | Lower initial cost but higher overall manufacturing cost |

Benefits of SMT in Modern Electronics

SMT offers several advantages that make it indispensable in today’s electronics:

- Reduced size and weight of components, enabling compact designs.

- Higher component density, allowing more functionality on a single PCB.

- Automated assembly processes, increasing efficiency and reducing costs.

- Enhanced reliability due to fewer mechanical stresses.

- Improved high-frequency performance with shorter signal paths.

How PCBA and SMT Work Together

Integration of SMT in PCBA

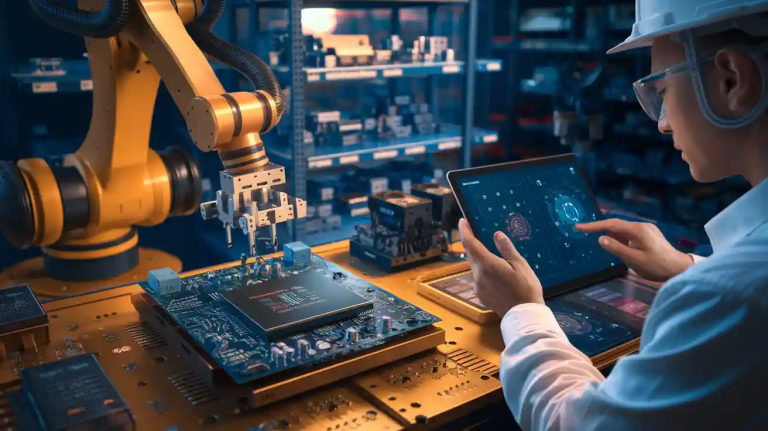

SMT plays a crucial role in modern PCB assembly. Automated machines place components onto the PCB with precision, while solder paste secures them in place. This integration streamlines the manufacturing process, ensuring high-quality results. SMT allows for double-sided PCB assembly, further optimizing space and functionality.

Why This Combination is Essential for Manufacturing

Combining SMT with PCBA has revolutionized electronics manufacturing. SMT enables the production of smaller, more compact devices while maintaining high reliability. Automated SMT lines ensure precise assembly and thorough testing, which are critical for industries like automotive and aerospace. This integration also reduces costs by minimizing manual labor and increasing production speed.

How Does SMT Work?

SMT Process Overview

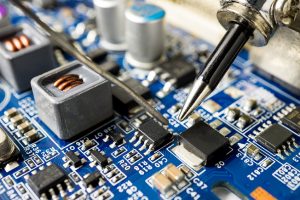

Solder Paste Application

The first step in smt assembly involves applying solder paste to the PCB. This paste contains tiny solder particles mixed with flux, which helps create strong electrical connections. A stencil ensures precise application by allowing the paste to cover only the designated solder pads. Accurate solder paste stenciling is critical because it determines how well components adhere to the board.

Component Placement with Pick-and-Place Machines

After applying the solder paste, pick-and-place machines position surface-mounted components (SMCs) onto the PCB. These machines use advanced vision systems to identify the correct placement for each component. Their speed and precision ensure that every part aligns perfectly with the solder pads. This step is vital for circuit reliability, as even minor misalignments can disrupt functionality.

Reflow Soldering for Securing Components

Reflow soldering solidifies the connections between components and the PCB. During this process, the board passes through a controlled heating system, melting the solder paste. As the board cools, the solder hardens, creating durable electrical bonds. This step is essential for ensuring the long-term performance of the smt assembly.

Quality Assurance in SMT

Inspection Methods Like Automated Optical Inspection (AOI)

Quality assurance plays a crucial role in smt assembly. Automated Optical Inspection (AOI) systems use cameras and software to detect defects such as misaligned components or soldering issues. AOI evaluates complex PCB designs with unmatched accuracy, ensuring that every board meets high standards. By identifying defects early, AOI reduces costs and improves overall product reliability.

Ensuring Product Reliability and Performance

Modern quality assurance methods go beyond inspection. Statistical Process Control (SPC) and real-time monitoring help maintain consistent production quality. Advanced testing strategies and traceability systems ensure that every smt assembly performs as expected. These measures enhance customer satisfaction and strengthen your product’s reputation in the market.

Why is PCBA SMT Important?

Advantages of PCBA SMT

Miniaturization of Devices

PCBA SMT has revolutionized how you experience compact electronics. By using both sides of the PCB, manufacturers can increase component density without enlarging the board. SMT components are significantly smaller and lighter than traditional through-hole parts. In fact, their volume can shrink by 60% to 70%, and their weight can drop by up to 80%. This allows for intricate designs in devices like smartphones and wearables. Higher circuit density also means more functionality packed into smaller spaces, enabling the creation of advanced, portable gadgets.

Cost-Efficiency in Production

The integration of SMT into PCB assembly reduces production costs. Automated machinery handles small components with high precision and speed, minimizing manual labor. This automation increases throughput and ensures repeatable processes, which lowers manufacturing errors. Additionally, placing components on both sides of the PCB optimizes space, reducing material costs. These factors make PCBA SMT a cost-effective solution for producing high-quality electronics.

Improved Reliability and Performance

SMT assembly enhances the reliability of your devices. Robust SMT joints reduce the risk of failure, even in demanding environments. Shorter lead lengths and fewer connection points improve signal integrity, ensuring better performance. Automated processes also maintain consistent quality, which is critical for industries like automotive and aerospace. With PCBA SMT, you can trust that your devices will perform reliably over time.

Role in Modern Electronics

Enabling Innovation in Consumer Electronics

PCBA SMT plays a vital role in advancing consumer electronics. It enables the production of smaller, lighter, and more powerful devices. Automated SMT lines ensure high-speed and precise manufacturing, meeting the growing demand for innovative products. From smartphones to gaming consoles, PCBA SMT allows manufacturers to push the boundaries of technology.

Surface mount technology has revolutionized electronics manufacturing, enabling the development of sophisticated devices that are compact and efficient.

Supporting IoT and Wearable Technology

The Internet of Things (IoT) and wearable devices rely heavily on PCBA SMT. These technologies require compact designs with high functionality, which SMT assembly makes possible. By increasing component density and reducing weight, SMT supports the creation of smartwatches, fitness trackers, and connected home devices. The precision and scalability of SMT processes ensure these products meet the demands of modern consumers.

Applications of PCBA SMT

Consumer Electronics

Smartphones, laptops, and portable devices

PCBA plays a vital role in the production of smartphones, laptops, and other portable devices. Surface mount technology allows manufacturers to place tiny components on both sides of the pcb. This increases functionality without increasing size. SMT assembly ensures these devices remain lightweight and compact while delivering high performance. For example, smartphones rely on dense pcb assembly to support advanced features like high-resolution cameras, fast processors, and long-lasting batteries. Similarly, laptops benefit from efficient pcba processes that enable slim designs and powerful computing capabilities.

Home appliances and entertainment systems

Modern home appliances and entertainment systems depend on pcba for their functionality. SMT assembly enables the integration of complex circuits into devices like smart TVs, gaming consoles, and sound systems. These products require precise pcb assembly to handle tasks such as wireless connectivity, high-definition video processing, and immersive audio output. In home appliances, pcba ensures reliable operation in devices like washing machines, refrigerators, and air conditioners. The compact design made possible by surface mount technology also allows for sleeker, more user-friendly designs.

Automotive Industry

Advanced driver-assistance systems (ADAS)

PCBA is essential for advanced driver-assistance systems (ADAS). SMT technology enables the precise placement of components that power features like adaptive cruise control, lane-keeping assistance, and collision avoidance. These systems rely on accurate pcb assembly to process real-time data from sensors and cameras. Additionally, in-car entertainment systems, including navigation and display screens, benefit from the efficiency of smt assembly. Safety systems like ABS and ESP also depend on robust pcba processes to ensure reliability under demanding conditions.

Electric vehicle control systems

Electric vehicles (EVs) rely heavily on pcba for their control systems. SMT ensures the precise mounting of tiny components on circuit boards, which is critical for the efficiency and reliability of EVs. The on-board control system acts as the “brain” of the vehicle, coordinating various electronic components like navigation, audio systems, and powertrain controls. SMT assembly supports the production of compact and efficient control modules, enabling EVs to deliver superior performance and energy efficiency.

Medical Devices

Wearable health monitors

Wearable health monitors, such as fitness trackers and smartwatches, depend on pcba for their compact and lightweight designs. SMT assembly allows manufacturers to integrate multiple functions, like heart rate monitoring and step tracking, into a single device. The high-density pcb assembly ensures these devices remain small while offering advanced features. This makes them ideal for continuous health monitoring and fitness tracking.

Diagnostic and imaging equipment

PCBA plays a critical role in diagnostic and imaging equipment used in healthcare. Surface mount technology enables the integration of complex circuits into devices like MRI machines, CT scanners, and portable ultrasound systems. These devices require precise pcb assembly to process large amounts of data quickly and accurately. SMT assembly ensures reliability and performance, which are essential for delivering accurate medical diagnoses.

Other Applications

Aerospace and Defense

PCBA plays a critical role in aerospace and defense systems. These industries demand high reliability and precision, which PCBA SMT delivers. You’ll find PCBs in avionics, radar systems, and communication devices. Surface mount technology allows manufacturers to create compact and lightweight designs, essential for aircraft and spacecraft. Smaller PCBs reduce weight, improving fuel efficiency and payload capacity.

In defense applications, PCBA ensures the durability of electronic systems under extreme conditions. SMT components withstand vibrations, temperature fluctuations, and mechanical stress. This makes them ideal for military-grade equipment like drones, navigation systems, and missile guidance. The automated nature of SMT assembly also ensures consistent quality, which is vital for mission-critical operations.

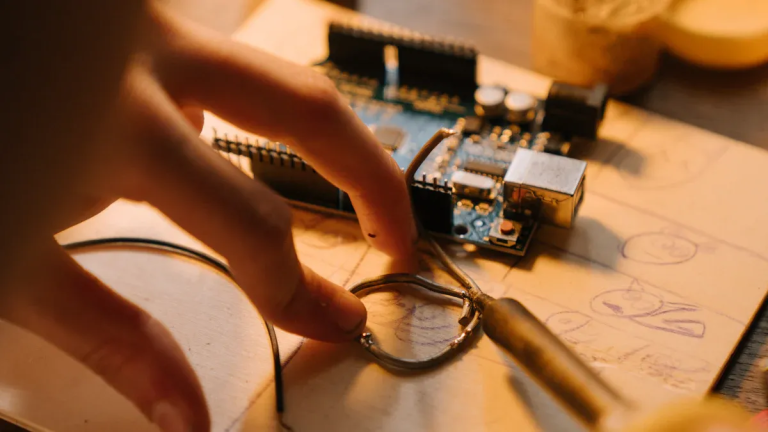

Industrial Automation and Robotics

PCBA SMT drives innovation in industrial automation and robotics. It enhances the efficiency and accuracy of component placement, which is crucial for robotic systems. With SMT, you can achieve complex designs in smaller spaces, enabling advanced robotic capabilities. For example, compact PCBs allow robots to perform intricate tasks in confined environments.

The use of advanced materials and manufacturing techniques improves thermal management and signal integrity. These features are essential for high-performance robotics, where precision and reliability are non-negotiable. Automation in PCB production speeds up prototyping and testing, helping you bring robotic designs to market faster. SMT also supports the integration of sensors and actuators, which are key components in automated systems.

In industrial settings, PCBA ensures the seamless operation of machinery and control systems. SMT’s ability to handle high-density circuits allows for smarter, more efficient automation solutions. Whether it’s assembly lines or warehouse robots, PCBA SMT enables the technology that powers modern industries.

PCBA SMT continues to push the boundaries of what’s possible in aerospace, defense, and industrial automation. Its precision and reliability make it indispensable for these advanced applications.

PCBA SMT stands as a cornerstone of modern electronics manufacturing. It combines advanced processes like solder paste application and precise component placement to create functional circuits. This technology enhances production efficiency, supports scalability, and ensures high precision. As electronics evolve, PCBA SMT will drive innovations like microelectronics, automation, and eco-friendly practices. Manufacturers will rely on its ability to handle complex designs and meet sustainability goals. With its compact design and cost efficiency, PCBA SMT will continue shaping the future of electronics, enabling smarter and more sustainable devices.

FAQ

What is the difference between SMT and THT?

SMT mounts components directly onto the PCB surface, while THT inserts component leads through drilled holes. SMT supports compact designs and automation. THT provides stronger mechanical bonds, making it ideal for high-stress applications like aerospace.

Tip: Use SMT for compact devices and THT for durability in extreme conditions.

Why is solder paste important in SMT?

Solder paste creates electrical connections between components and the PCB. It ensures components stay securely attached during reflow soldering. Without it, circuits would fail to function properly.

Note: Precise solder paste application improves reliability and reduces defects.

Can SMT handle all types of components?

SMT works best for small, lightweight components. Larger or high-power components may require THT for better mechanical support. Combining both methods ensures optimal performance.

Emoji Insight: 🛠️ SMT = Compact; THT = Durable.

How does SMT improve production efficiency?

SMT uses automated machines for component placement and soldering. This reduces manual labor, speeds up production, and minimizes errors. It also allows double-sided PCB assembly, maximizing space.

Did You Know? SMT can place thousands of components per hour with high precision.

Is PCBA SMT eco-friendly?

Yes, SMT reduces material waste by using smaller components and efficient processes. Automation also lowers energy consumption. These factors contribute to more sustainable manufacturing.

🌱 Eco Tip: Choose SMT for greener electronics production.