Rigid-Flex PCB

- Home

- Rigid-Flex PCB

Rigid-Fkex PCB

- Home

- Rigid-Fkex PCB

Advantages of Rigid-Flex PCB Production

Why Choose Us

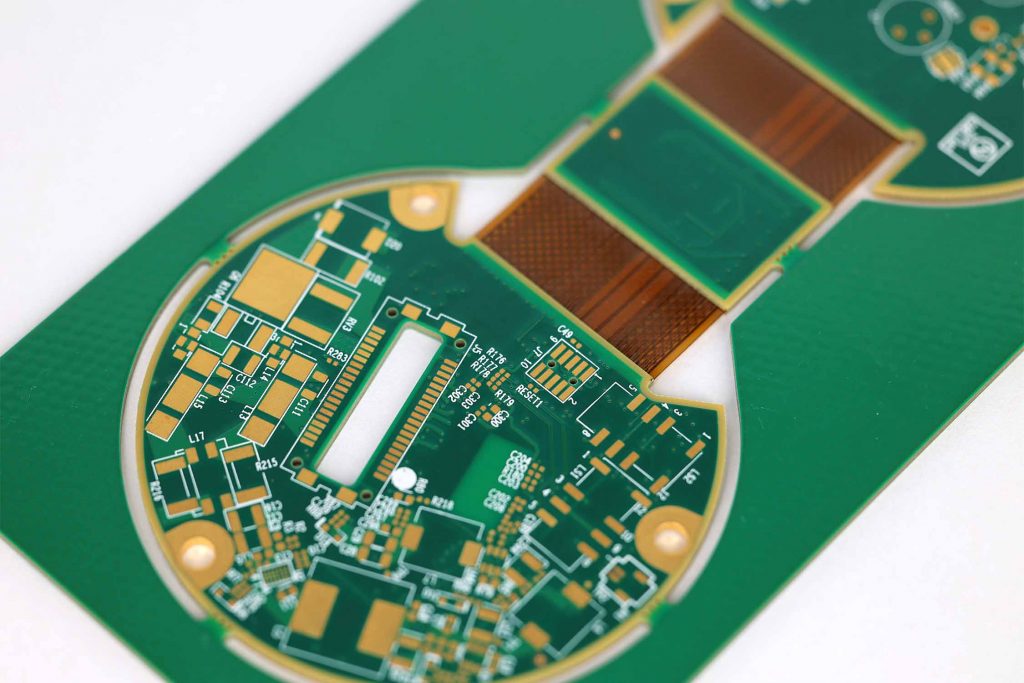

Expert Rigid-Flex PCB Manufacturing

We specialize in producing high-quality rigid-flex PCBs, leveraging extensive experience and advanced equipment. Our rigid-flex PCBs are not only structurally reliable but also provide excellent electrical performance, making them ideal for compact and complex electronic devices requiring high stability and precision.

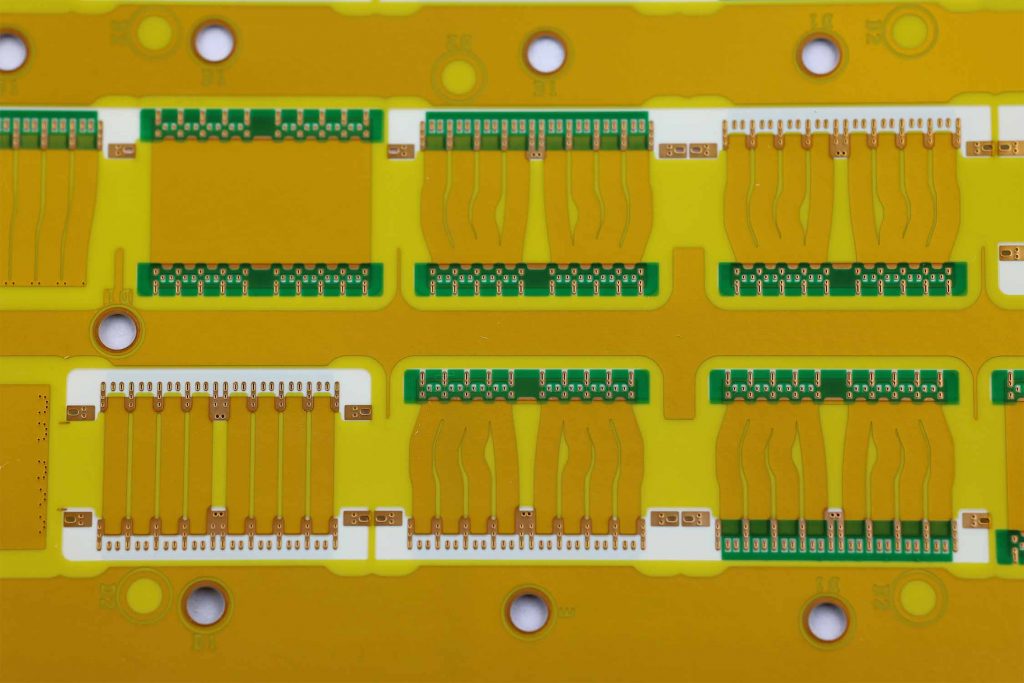

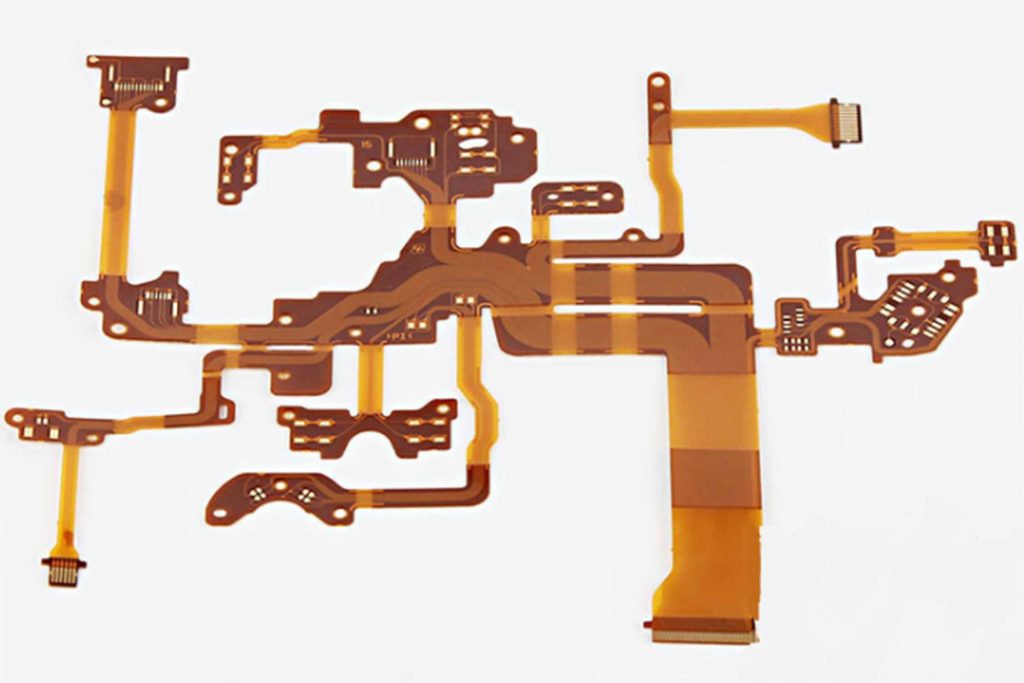

Support for Complex Designs

We offer multilayer, high-density rigid-flex PCBs that meet the needs of complex circuit designs and stringent space constraints. Whether for industrial control systems, medical devices, or consumer electronics, our products cater to demands for miniaturization, high performance, and flexible connections, with exceptional design and engineering support.

Flexible Customization

To meet the diverse needs of our clients, we provide flexible customization services. From material selection and thickness configuration to specialized functional designs, we tailor rigid-flex PCB solutions according to specific application requirements, ensuring optimal performance in various use cases.

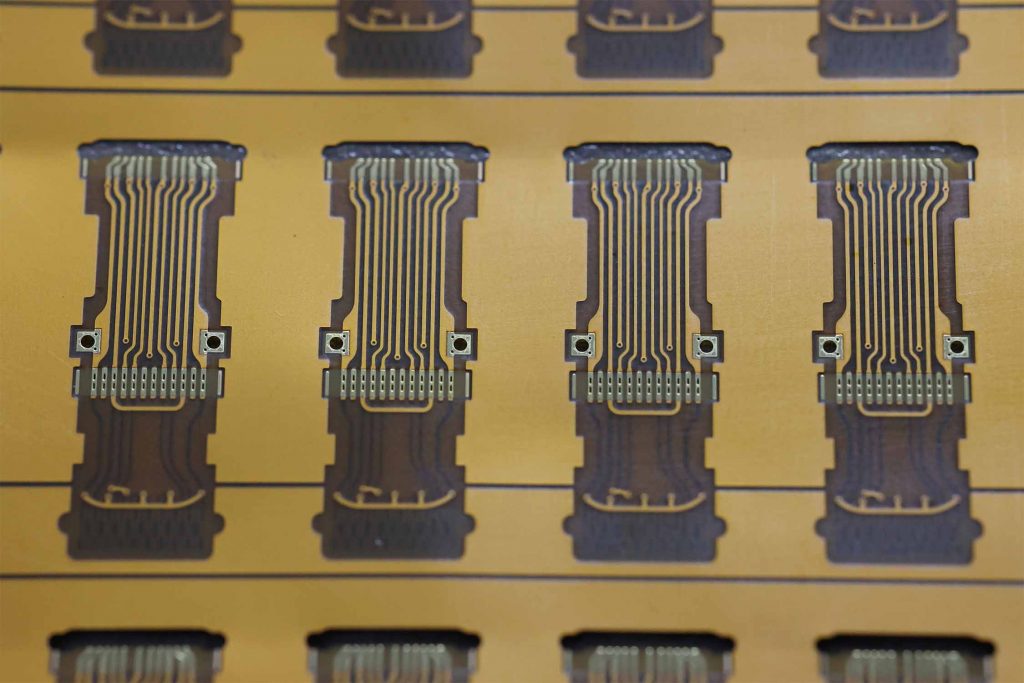

High Reliability and Durability

Every step of our rigid-flex PCB manufacturing process undergoes strict quality control to ensure high reliability and durability. Rigorously tested and inspected, our products perform consistently even under high stress and harsh environments, making them suitable for demanding industries such as aerospace, automotive electronics, and high-end consumer electronics.

production capacity

| Items | Rigid-flex |

| Material | FR-4,FPC High-frequency |

| Layers | 1-40L |

| Max cut lamination size | 500*420mm |

| Final board thickness | 0.20-6.0mm |

| Min Final Hole size | 0.075mm |

| Aspect Ratio | 14:01 |

| Inner layer Line Width/Space | 0.05mm |

| Copper Foil Thickness (Inner Layers) | 1/6oz-1oz |

| Min dielectric layer thickness | 20um |

| Copper Foil Thickness (Outer Layers) | 1/3oz-1oz |

| Copper to drill distance | 0.2mm |

| Out layer Line width/space | 0.035mm |

| Min SMD width | 0.05mm |

| Max Solder Mask Plug Hole Diameter | 0.5mm |

| solder mask strip width | 0.075mm |

| Final Set Size Tolerance | ±0.1mm/limit±0.05mm |

| Min Hole to board edge Distance | 0.075-0.15mm |

| Min Beveling angle Tolerance | ±3-5° |

| Layer to layer Tolerance | ≤0.075mm(1-6L) |

| Inner layer Min PTH Annular Ring | 0.15mm |

| Out layer Min PTH Annular ring | 0.15mm |

| Surface Treatment | OSP、HASL 、ENIG、Gold Finger、Plating Gold 、ENEPIG、IMM TIN、IMM AG |

| Warp&Twist | 0.5%(less than 45u) |

PCB factory display

Frequently Asked Questions

To start PCB manufacturing, we would require various design files including Gerber Files, Bill of Materials (BOM) file, Assembly drawings, Preliminary files or any other special requirements file.

The lead time for such boards is 1 to 2 weeks; however, it will depend on the bespoke requirements.

We manufacture rigid flex circuit boards, rigid PCBs and flex PCBs in accordance with UL, ISO-9001, AS 9100, IPC-6012/6013 and MIL performance standards.

We offer Immersion Ni/Au and OSP. We also provide custom surface finishing or plating for rigid flex circuit boards.

We use FR4, steel or aluminum.