Imagine a world where your keyboard not only enhances your productivity but also prioritizes your comfort. Recent breakthroughs in keyboard design, keyboard manufacturing, and keyboard assembly have revolutionized how keyboards are created and used. These advancements in keyboard design have made ergonomic keyboards more accessible, reducing hand discomfort by 25% and boosting user comfort and productivity. With mechanical keyboards now lasting up to 50 million keystrokes, their durability and quality far surpass traditional options.

The rise of customization has also empowered you to tailor your keyboard to your unique needs. From hot-swappable switches to compact layouts, these innovations in keyboard assembly ensure your typing experience is both efficient and enjoyable. As the ergonomic keyboard market grows by 10% annually, it’s clear that these technical strides in keyboard manufacturing are reshaping the industry for the better.

Key Takeaways

- Ergonomic keyboards lower hand pain by 25%, making typing easier.

- Hot-swappable switches let you change keys easily without soldering.

- The ergonomic keyboard market grows 10% yearly due to health focus and remote work.

- Automated manufacturing makes keyboards faster and better in quality.

- Eco-friendly materials and modular designs cut down on e-waste, helping the planet.

Evolution of the Keyboard Industry

From Early Mechanical Keyboards to Modern Designs

The journey of keyboards has been remarkable. Early mechanical keyboards, known for their durability and tactile feedback, set the foundation for modern designs. These keyboards could withstand up to 50 million keystrokes, a stark contrast to the 5-10 million keystrokes of membrane keyboards. Over the past two years, mechanical keyboards have seen a 60% surge in sales, reflecting their growing popularity among users who value quality and performance.

Modern designs have taken this legacy further. Today’s keyboards offer advanced features like hot-swappable switches, customizable layouts, and wireless connectivity. These innovations cater to diverse needs, from gamers seeking precision to professionals prioritizing efficiency. The evolution of keyboard design has not only enhanced functionality but also redefined user expectations.

| Aspect | Detail |

|---|---|

| Popularity Surge | 60% increase in mechanical keyboard sales over the past two years. |

| Durability Factor | Mechanical keyboards can withstand up to 50 million keystrokes, compared to 5-10 million for membrane keyboards. |

The Role of the Ergonomic Keyboard Market in Driving Innovation

The ergonomic keyboard market has become a driving force behind innovation. Companies are investing heavily in research and development to create designs that enhance comfort and productivity. Split keyboards, adjustable layouts, and wireless technology are just a few examples of how ergonomic designs are transforming the industry.

- Manufacturers now prioritize customization to meet specific ergonomic needs.

- The rise of remote work has increased demand for ergonomic keyboards, as users seek solutions to reduce strain and improve posture.

- Awareness of health benefits has encouraged consumers to invest in ergonomic devices.

This market’s growth, at 10% annually, highlights its influence. As new players enter the scene, competition drives further advancements, ensuring you benefit from cutting-edge designs that prioritize your well-being.

Customization Trends and Their Influence on the Industry

Customization has reshaped the keyboard industry. Consumers now demand keyboards that reflect their personal style and functional preferences. This trend is particularly evident in the gaming keyboard market, where features like unique keycaps and adjustable backlighting enhance the user experience. The custom keyboard scene has also gained traction, offering enthusiasts the opportunity to build keyboards tailored to their exact specifications.

The shift towards customization underscores a broader desire for individuality in technology. By offering personalized features, manufacturers not only attract consumers but also foster a deeper connection between users and their devices. Whether you’re a gamer, a professional, or a hobbyist, customization ensures your keyboard meets your unique needs.

Breakthroughs in Keyboard Design

PCB Advancements in Keyboard Design

Hot-Swappable PCBs for User Flexibility

Hot-swappable PCBs have revolutionized keyboard pcb design by allowing you to replace switches without soldering. This innovation empowers you to customize your keyboard effortlessly, whether you prefer tactile, clicky, or linear switches. It also extends the lifespan of your keyboard by enabling easy repairs and upgrades. With hot-swappable PCBs, you can experiment with different switch types to find the perfect balance between performance and comfort.

Multi-Layered PCBs for Enhanced Functionality

Multi-layered PCBs have elevated keyboard performance and efficiency to new heights. These advanced designs integrate multiple layers of circuitry, enabling features like per-key RGB lighting, wireless connectivity, and programmable macros. The seamless firmware integration in these PCBs minimizes signal loss, ensuring a responsive typing experience.

| Metric/Advancement | Description |

|---|---|

| Enhanced Durability | Use of innovative materials and design techniques to withstand prolonged usage. |

| Wireless Connectivity | Integration of wireless technology for improved user experience. |

| Customization | Development of programmable firmware for personalized key layouts and macros. |

| Energy Efficiency | Implementation of energy-efficient components to reduce power consumption. |

| Seamless Firmware Integration | Advanced circuit layout techniques to minimize signal loss and improve responsiveness. |

Ergonomic Innovations in Keyboard Layouts

Split and Adjustable Keyboards for Comfort

Split ergonomic travel keyboards are redefining comfort in the ergonomic keyboard market. These designs allow you to position each half of the keyboard independently, reducing strain on your wrists and shoulders. Adjustable layouts further enhance this flexibility, letting you fine-tune the angle and height for optimal posture. Studies show that switching to ergonomic keyboards reduces hand discomfort by 25%, making them an essential tool for improving your typing experience.

- Increasing awareness of health and wellness among consumers is driving demand for ergonomic keyboards.

- Ergonomic keyboards are seen as essential for enhancing user experience and comfort.

- The focus on personal well-being is leading to investments in ergonomic solutions.

Compact Layouts for Portability and Efficiency

Compact layouts combine portability with functionality, making them ideal for professionals and gamers alike. These keyboards eliminate unnecessary keys while retaining essential features, ensuring a clutter-free workspace. Their lightweight design makes them perfect for travel, while their efficient layouts boost productivity by keeping all critical keys within easy reach.

Material Innovations in Keyboard Design

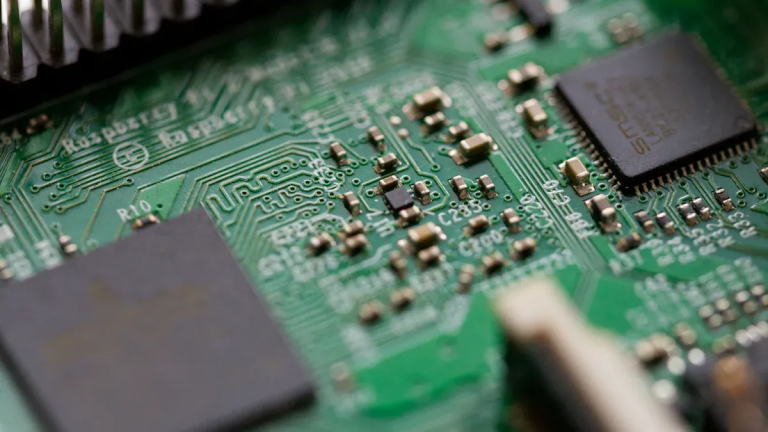

High-Durability Switches and Keycaps

Material advancements have significantly improved the durability and quality of keyboards. Mechanical keyboards now last up to 50 million keystrokes, compared to just 5-10 million for membrane keyboards. High-quality switches and reinforced keycaps ensure your keyboard can withstand rigorous use without compromising performance.

| Keyboard Type | Durability (Keystrokes) |

|---|---|

| Mechanical Keyboard | Up to 50 million |

| Membrane Keyboard | 5 to 10 million |

Lightweight and Sustainable Materials

Sustainability is becoming a priority in keyboard design. Manufacturers are adopting lightweight and eco-friendly materials to reduce environmental impact. These materials not only make keyboards more portable but also align with the growing demand for sustainable products. By choosing keyboards made from sustainable materials, you contribute to a greener future without sacrificing performance or durability.

Innovations in Keyboard Manufacturing Processes

Automation and Precision in Keyboard Manufacturing

CNC Machining for Custom Cases

CNC machining has transformed how custom keyboard cases are produced. This technology allows you to enjoy cases with intricate designs and precise dimensions, ensuring a perfect fit for your keyboard components. By automating the cutting and shaping process, CNC machining reduces production time and enhances quality. It also enables manufacturers to create unique designs tailored to your preferences, making customization more accessible than ever.

- CNC machining shortens cycle times by optimizing tool paths.

- Improved milling techniques ensure consistent quality and reduce the need for manual intervention.

The integration of AI in CNC machining further boosts efficiency by enabling real-time adjustments and predictive maintenance. This ensures that every production run meets the highest standards of performance and efficiency.

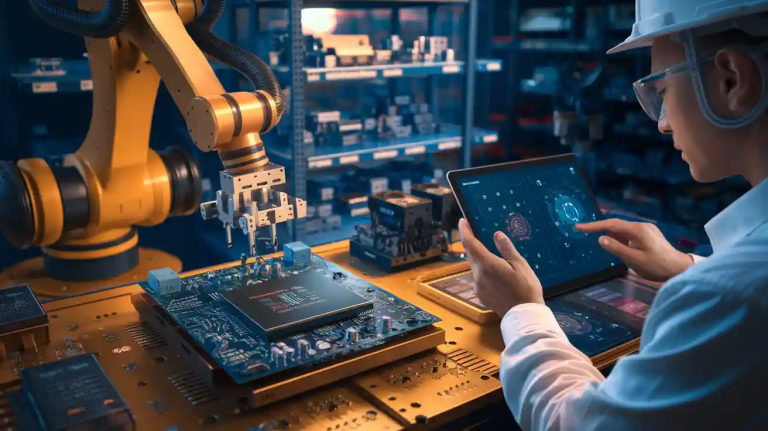

Robotic Assembly for Consistency and Speed

Robotic assembly has revolutionized keyboard manufacturing by delivering unmatched precision and speed. Robots can assemble keyboards with consistent quality, eliminating human errors. This means you get a product that performs reliably, whether you’re typing or gaming. Robotic systems also streamline production, allowing manufacturers to meet the growing demand for ergonomic keyboards without compromising on quality.

The ergonomic keyboard market, valued at $1.8 billion in 2022, continues to grow at a CAGR of 8.5%. Automation plays a key role in this expansion by reducing costs and increasing the availability of ergonomic and customizable solutions.

Advanced Fabrication Techniques

Injection Molding for Keycaps

Injection molding has become the go-to method for producing durable and visually appealing keycaps. This technique allows manufacturers to create keycaps with intricate details and vibrant colors, enhancing both aesthetics and functionality. For you, this means access to keyboards with high-quality keycaps that withstand heavy use while maintaining their appearance.

Laser Etching for Key Legends

Laser etching ensures that key legends remain clear and legible, even after years of use. This process uses precision lasers to engrave legends onto keycaps, providing a durable and fade-resistant finish. Whether you’re a gamer or a professional, laser-etched keycaps guarantee a seamless typing experience.

Wireless Integration in Keyboard Manufacturing

Bluetooth and Low-Latency Wireless Modules

Wireless keyboards have become a staple in modern setups, thanks to advancements in Bluetooth and low-latency wireless modules. These technologies allow you to connect your keyboard to multiple devices effortlessly, ensuring a stable and secure connection even in environments with high wireless interference.

Power Efficiency and Battery Life Enhancements

Continuous innovation in battery technology has significantly improved the battery life of wireless keyboards. You can now enjoy extended usage without frequent recharging, making wireless keyboards more convenient and reliable. Enhanced power efficiency also reduces energy consumption, aligning with the growing demand for sustainable products in the ergonomic keyboard market.

Advances in Keyboard Assembly Processes

Modular Designs for Simplified Keyboard Assembly

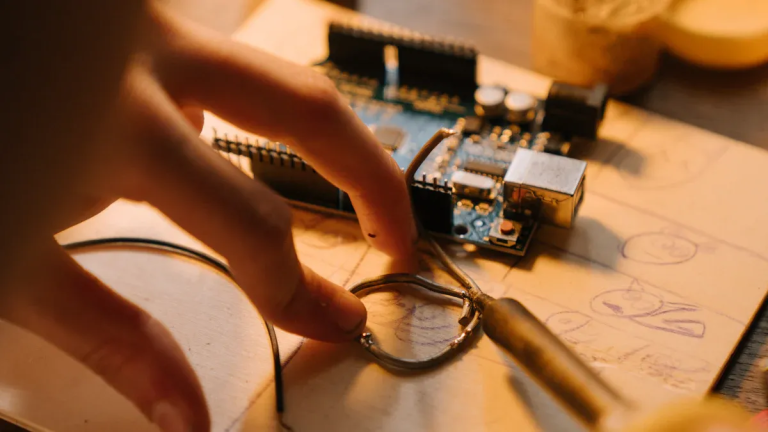

Tool-Free Assembly for End-Users

Imagine assembling your keyboard without needing any tools. Tool-free assembly has made this possible, allowing you to customize and maintain your keyboard effortlessly. You can swap out switches, keycaps, or even entire modules with just your hands. This innovation not only saves time but also makes customization accessible to everyone, regardless of technical expertise. Whether you’re a gamer or a professional, tool-free assembly ensures your keyboard adapts to your needs with ease.

Pre-Lubed Switches for Enhanced Performance

Pre-lubed switches take your typing experience to the next level. These switches come pre-applied with lubrication, ensuring smoother keystrokes and reduced noise. You no longer need to spend hours manually lubing switches to achieve optimal performance. Pre-lubed switches enhance both performance and efficiency, making them a favorite among enthusiasts and casual users alike. With this feature, your keyboard delivers a premium feel right out of the box.

Quality Assurance in Keyboard Assembly

Automated Testing for Durability and Consistency

Automated testing ensures every keyboard meets the highest quality standards. Machines rigorously test each unit for durability and consistency, simulating millions of keystrokes to guarantee reliability. This process eliminates human error, ensuring you receive a keyboard that performs flawlessly. Automated testing also accelerates production, allowing manufacturers to meet the growing demand in the ergonomic keyboard market without compromising quality.

AI-Assisted Visual Inspections

AI-assisted visual inspections add another layer of precision to keyboard assembly. Advanced algorithms analyze each keyboard for defects, such as misaligned keycaps or faulty switches. This technology catches issues that might go unnoticed during manual inspections, ensuring every keyboard meets strict quality benchmarks. For you, this means a product that not only looks great but also performs reliably for years to come.

Tip: When choosing a keyboard, look for features like tool-free assembly and pre-lubed switches. These innovations enhance usability and ensure a superior typing experience.

Software and Firmware Integration in Keyboards

Customizable Firmware for Enhanced Functionality

Per-Key RGB Lighting and Macro Programming

Customizable firmware has transformed how you interact with your keyboard. Features like per-key RGB lighting allow you to personalize your keyboard’s appearance, creating a vibrant and unique workspace. Whether you want a calming gradient for focus or dynamic effects for gaming, the choice is yours. Macro programming takes this customization further by letting you assign complex commands to single keys. This feature boosts your productivity and enhances your gaming performance by streamlining repetitive tasks.

Layering and Advanced Typing Features

Layering in firmware enables you to assign multiple functions to a single key, maximizing your keyboard’s efficiency. You can switch between layers for different tasks, such as typing, gaming, or coding, without needing extra keys. Advanced typing features, like predictive text and error correction, improve your typing speed and accuracy. These innovations ensure your keyboard adapts to your needs, enhancing both performance and efficiency.

Open-Source Ecosystems for Keyboard Software

QMK and VIA for Customization

Open-source platforms like QMK and VIA have revolutionized keyboard customization. QMK firmware offers you unparalleled control over your keyboard’s functionality, from remapping keys to creating custom macros. VIA simplifies this process with a user-friendly interface, allowing you to make real-time adjustments without technical expertise. These tools empower you to design a keyboard experience tailored to your preferences, whether you prioritize ergonomics, aesthetics, or functionality.

Community Contributions to Firmware Development

The open-source community plays a vital role in advancing keyboard software. Developers worldwide collaborate to create innovative features and improve existing firmware. This collective effort ensures you benefit from cutting-edge technology and robust quality. The growing popularity of ergonomic keyboards has driven the development of customizable ergonomic solutions, making it easier for you to find a keyboard that meets your specific needs.

Did you know? The computer keyboard market is projected to grow from $5.78 billion in 2024 to $7.90 billion by 2034, driven by advancements in software and firmware. This growth reflects the increasing demand for ergonomic designs and smart features, ensuring you have access to high-quality, customizable keyboards.

Future Trends and Challenges in the Keyboard Industry

Emerging Technologies in Keyboard Design and Manufacturing

Haptic Feedback and Force Sensors

Imagine typing on a keyboard that provides tactile feedback for every keystroke. Haptic feedback is transforming how you interact with keyboards by simulating the sensation of pressing physical keys, even on touch-sensitive surfaces. This technology enhances your typing experience, making it more intuitive and satisfying. Force sensors add another layer of innovation by detecting the pressure you apply to each key. These sensors allow for dynamic input, enabling features like variable typing speeds or pressure-sensitive shortcuts. These advancements in ergonomic designs ensure that your keyboard adapts to your unique typing style, boosting both performance and efficiency.

AI-Powered Typing Assistance

AI-powered typing assistance is revolutionizing the ergonomic keyboard market. Imagine a keyboard that learns your typing habits and predicts your next word with remarkable accuracy. AI technologies are making this possible, offering features like real-time error correction and personalized ergonomic support. These smart keyboards not only improve your typing speed but also reduce strain by optimizing key layouts based on your usage patterns. With AI, your keyboard becomes a tool that enhances productivity while prioritizing your comfort.

Sustainability Challenges in the Ergonomic Keyboard Market

Reducing E-Waste in Manufacturing Processes

The ergonomic keyboard market faces a pressing challenge: reducing e-waste. Manufacturers are adopting sustainable practices, such as using recyclable materials and modular designs, to minimize environmental impact. Modular keyboards allow you to replace individual components instead of discarding the entire device, extending its lifespan. By choosing keyboards made with eco-friendly materials, you contribute to a greener future while enjoying the same level of quality and performance.

Balancing Customization with Scalability

Customization is a cornerstone of the ergonomic keyboard market, but it poses challenges for scalability. Manufacturers must balance the demand for personalized ergonomic support with the need for efficient production. Advanced technologies like 3D printing and CNC machining are helping bridge this gap, enabling the creation of custom designs at scale. These innovations ensure you get a keyboard tailored to your needs without compromising on quality or affordability.

Note: The future of the ergonomic keyboard market lies in combining cutting-edge technologies with sustainable practices. By embracing these trends, you can enjoy a keyboard that offers unparalleled comfort, functionality, and environmental responsibility.

The advancements in keyboard design, keyboard manufacturing, and keyboard assembly have reshaped the ergonomic keyboard market. These breakthroughs have made ergonomic keyboards more accessible, improving your comfort and productivity. Innovations like hot-swappable switches, modular assembly, and sustainable materials ensure you enjoy a personalized typing experience without compromising quality. The focus on ergonomic design has also reduced strain and enhanced usability, making keyboards an essential tool for modern workspaces. By choosing these cutting-edge solutions, you gain functionality, customization, and sustainability in one package.

FAQ

What makes mechanical keyboards better than membrane keyboards?

Mechanical keyboards offer superior durability, tactile feedback, and customization options. They last longer and provide a more satisfying typing experience. Their advanced design ensures you can tailor them to your preferences, making them ideal for both gaming and professional use.

How do hot-swappable PCBs improve the keyboard experience?

Hot-swappable PCBs let you replace switches without soldering. This feature allows you to customize your keyboard easily and experiment with different switch types. It also extends the keyboard’s lifespan by simplifying repairs and upgrades.

Are ergonomic keyboards worth the investment?

Yes, ergonomic keyboards reduce strain and improve typing comfort. Their split and adjustable designs promote better posture, making them essential for long typing sessions. Investing in one enhances your productivity and protects your health.

How does automation improve keyboard manufacturing quality?

Automation ensures consistent assembly and reduces human error. Techniques like robotic assembly and CNC machining produce keyboards with precise designs and reliable performance. This guarantees you receive a high-quality product every time.

Can I customize my keyboard without technical expertise?

Absolutely! Many modern keyboards feature tool-free assembly and user-friendly software. You can swap keycaps, switches, and even program macros without needing advanced skills. These innovations make customization accessible to everyone.