A mechanical control panel is key to running industries smoothly. It helps control machines and processes with great accuracy. It brings everything together, making sure parts work well together. Its strong build lowers dangers, keeping workers safe. It works well for tasks like running conveyor belts or controlling temperatures. This tool boosts work speed and cuts down mistakes. Adding it to your system gives you a dependable way to handle tough industrial jobs.

Key Takeaways

- Mechanical control panels are important for safe and smooth factory work. They keep controls in one place, lowering errors and boosting safety.

- Taking care of control panels often is very important. It finds small problems early, stops big failures, and keeps them working well.

- Customizing control panels helps factories with special needs. Adding tools like PLCs makes them work better and faster.

- Using smart technology with control panels makes them more useful. It lets workers check them live and control them from far away, making work easier.

- Buying good control panels saves money over time. Their strong design and good heat handling mean less fixing and fewer delays.

Understanding Mechanical Control Panels

What Is a Mechanical Control Panel?

A mechanical control panel is a system that controls machines. It works like the brain of an industrial setup. It ensures machines run safely and efficiently. These panels have circuits that send signals to guide equipment. They are built for safety, reliability, and efficiency, making them vital in industries.

Did you know? The global control panel market may reach $10.3 billion by 2032. This shows how important they are in modern industries.

These panels are tough and can handle harsh conditions. They follow rules and consider the environment to last long. Whether controlling conveyor belts or adjusting temperatures, they are reliable tools.

Key Components of Control Panels

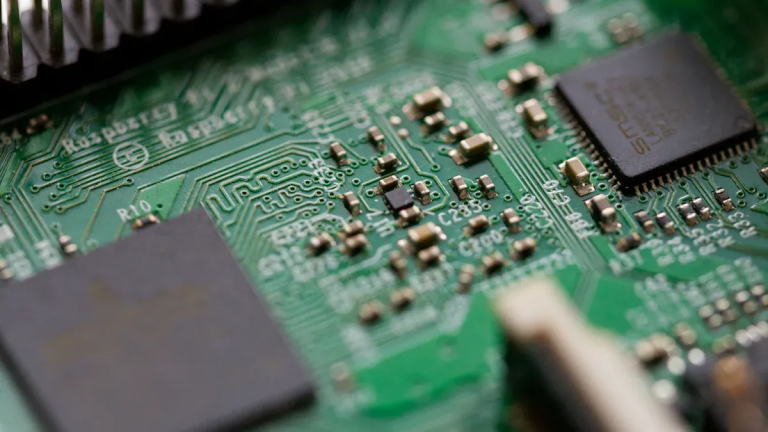

Control panels have important parts that help manage machines. The enclosure, made of aluminum or stainless steel, protects the inside from dust and water. Its size and safety features decide if it works indoors or outdoors.

Inside, the back panel holds electrical parts like circuit breakers, relays, and PLCs. Each part has a job. Circuit breakers stop electrical overloads, and PLCs automate tasks like starting machines.

Heat and vibrations are also important to manage. Smaller, stronger parts need good heat control to avoid overheating. Strong housing keeps the panel safe from vibrations and heavy use.

How Control Panels Function in Industrial Systems

Control panels are the control center for machines. They take input signals, process them, and send output signals. This helps machines work as needed. For example, they can control conveyor belt speed or keep temperatures steady.

Custom panels can be made for specific needs. Whether for advanced tasks or simple ones, they can adjust to fit. They also connect with other systems, making them useful for many industries.

By centralizing control, these panels make operations easier. They lower mistakes, improve safety, and boost efficiency. With a mechanical control panel, your machines can run smoothly and reliably.

Benefits of Mechanical Control Panels

Enhancing Safety and Reliability

A mechanical control panel helps keep workplaces safe and reliable. It reduces mistakes by centralizing control and lowering accident risks. Features like circuit breakers stop electrical problems, protecting people and machines. Clear labels and proper wiring make it safer to use. For example, diagrams and layouts help workers fix problems faster, avoiding delays.

These panels are also very dependable. They are made to handle tough conditions like heat and vibrations. Their strong design ensures they work well even in hard environments. When you choose a good control panel, you get a system that keeps workers safe and jobs running smoothly.

Improving Operational Efficiency

Control panels make industrial work faster and easier. They automate repeated tasks, so less manual work is needed. For instance, they can control conveyor speeds or keep temperatures steady. This saves time and makes work more accurate, avoiding costly mistakes.

They also make managing systems simpler. With one control point, you can adjust many machines at once. This setup boosts productivity and lets you focus on important tasks. A mechanical control panel is a must-have for better efficiency in industries.

Customization for Industrial Needs

Every industry has different needs, and control panels can be customized. You can add features like PLCs or HMI panels to fit your work. Certified panels meet safety rules and work at high performance. Good setup helps avoid problems and improves efficiency.

Customization also includes support after installation. Many makers offer help to fix any issues quickly. Clear labels and guides make training and maintenance easier. Whether for small or big operations, custom panels match your goals perfectly.

Maintaining Mechanical Control Panels

Why Maintenance Matters

Taking care of mechanical control panels is very important. Regular checks help find small problems early. Fixing these stops bigger, costly issues later. Maintenance also makes your panels last longer. This saves money and keeps them working well. It also reduces downtime, helping you meet work goals on time.

Pro Tip: Write down all maintenance work. This helps track how well your panels are doing. Use this information to plan checks and upgrades.

Skipping maintenance can cause sudden breakdowns and safety risks. It can also slow down work. By keeping up with maintenance, you make your workplace safer and your systems more reliable.

How to Maintain Control Panels

Good care keeps your control panels working well. Follow these tips:

- Ground wires correctly to avoid electrical shocks or accidents.

- Organize wires neatly to make repairs easier and safer.

- Group parts in a way that makes fixing problems simple.

- Watch temperatures to stop parts from overheating or breaking.

- Use safety labels to warn about electrical dangers.

These steps make your panels safer and work better. Paying attention to these details keeps them reliable for a long time.

Stopping Downtime and Problems

Downtime can stop work and cost a lot of money. To prevent this, check your panels for signs of wear. Replace broken parts before they cause bigger problems. Regular checks help you spot issues early.

Industries like factories and energy plants need panels to work nonstop. By taking care of them, you avoid failures and keep everything running smoothly. A good maintenance plan saves time and money while keeping your systems strong.

The Role of Control Panels in Future Industries

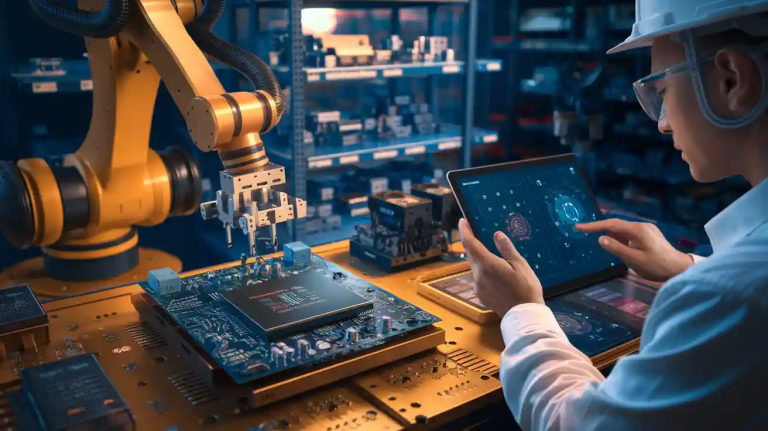

Integration with Smart Technologies

The future of control panels is in smart technology. Industries now use IoT devices, sensors, and cloud systems. Control panels can connect to these for better performance. They collect data and show real-time updates. This helps you fix problems faster. For example, a smart panel can warn about overheating early.

Smart features make control panels more flexible. They can change settings automatically when needed. This saves time and reduces manual work. Remote access lets you control systems from anywhere. This keeps work running smoothly. Combining strong design with smart tech makes these panels essential.

Trends in Industrial Automation

Automation is changing how control panels are made and used. Smaller parts and more heat need better cooling systems. Without cooling, parts can break and cause safety risks. Strong designs help panels handle heavy use and vibrations.

New trends focus on panels that can grow with your needs. Modular designs let you add or change parts easily. Advanced tools now find problems early, saving repair costs. These features keep panels working well for a long time. By following these trends, your panels stay ready for the future.

Mechanical control panels are very important in industries today. They keep systems safe, efficient, and flexible. Their strong build and smart features help manage tough tasks. Using these panels lowers downtime, saves money, and boosts productivity.

| Feature | Why It Matters | Benefits and Savings |

|---|---|---|

| Strong Build | Tough panels stop vibrations and last a long time | Cuts down on breakdowns and work delays |

| Heat Control | Good heat control keeps parts working longer | Lowers repair costs and makes equipment last longer |

| Vibration Protection | Knowing how to handle vibrations protects delicate parts | Saves money on fixing or replacing damaged parts |

To get the most out of them, take care of your panels often. This keeps them working well, makes parts last longer, and avoids sudden problems. Adding smart tech makes them even better, helping you stay ahead in automated industries.

Pro Tip: Regular care not only keeps things safe but also saves money. It’s a key part of running industries successfully.

FAQ

What industries use control panels the most?

Factories, energy plants, and shipping companies depend on control panels. These panels run conveyor belts, control heat, and handle repeated tasks. Their flexibility makes them important for jobs needing accuracy and speed.

How does maintenance help control panels work better?

Maintenance keeps control panels working well. It stops overheating, reduces part damage, and avoids delays. Fixing small problems early saves money and makes equipment last longer.

Can control panels be made for special needs?

Yes, control panels can be designed for specific tasks. You can add tools like PLCs or HMIs to improve how they work. Custom panels match your work needs and follow safety rules.

What are the unique uses of mechanical control panels?

Mechanical control panels work well in tough places. They handle high heat, shaking, and heavy work. Their strong build makes them perfect for mining, oil, and big factories.

How do control panels make workplaces safer?

Control panels manage machines in one place, lowering mistakes. Safety features like circuit breakers and labels keep workers safe. By automating tasks, they reduce accidents and follow safety laws.