Choosing the best PCB assembly manufacturer can improve your electronics greatly. A good manufacturer provides strong, accurate, and quick results. You need a partner who cares about top quality. Don’t choose poorly—pick experts to stay ahead in electronics.

Key Takeaways

- Picking a great PCB maker improves your electronics’ quality.

- Find makers with good certifications like IPC-A-610 and ISO 9001.

- Quick delivery is important; choose one that works fast.

Overview of the PCB Assembly Industry

What is PCB Assembly?

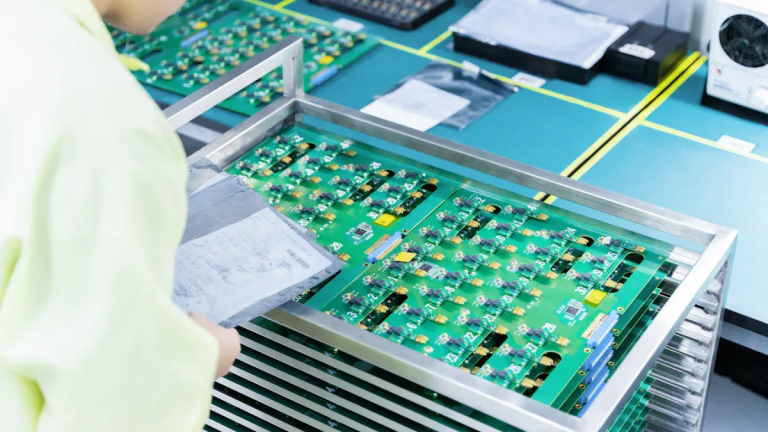

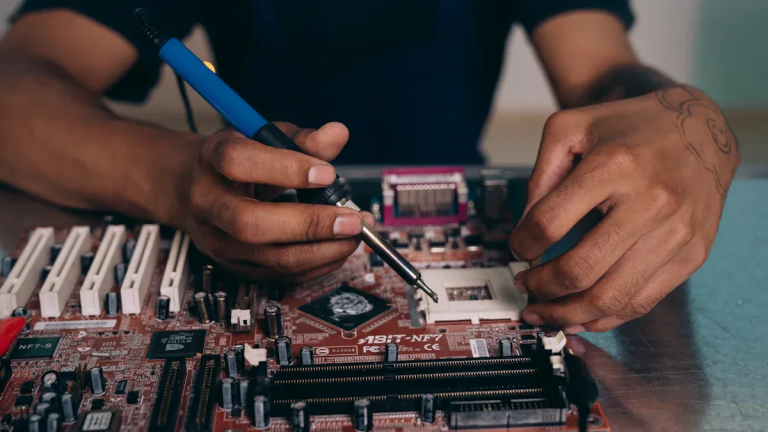

PCB assembly means putting electronic parts onto circuit boards. This process makes devices work properly. It uses methods like surface-mount technology (SMT) and through-hole assembly. These ways help parts stay in place and work well. PCB assembly services are important for making precise and reliable electronics.

Why PCB Assembly is Critical for Electronics Manufacturing

PCB assembly helps devices work reliably and perform well. Clear assembly plans prevent mistakes. First article inspections (FAI) check parts placement to avoid errors. Manufacturers review processes often to improve quality and reduce problems. Without good assembly, even great designs can fail. This can cause expensive fixes and unhappy customers.

Trends and Innovations in the PCB Assembly Industry

The PCB industry is changing fast with new technology and needs. Important trends include:

- More demand for gadgets like smartphones and smartwatches.

- Growth in car electronics due to electric and self-driving cars.

- More IoT devices needing complex PCB assemblies.

In 2023, North America’s PCB market was worth $14.5 billion. By 2032, it may grow to $19.5 billion. Automation and AI are speeding up production and finding mistakes. For instance, Tempo Automation finishes orders in three days using smart software.

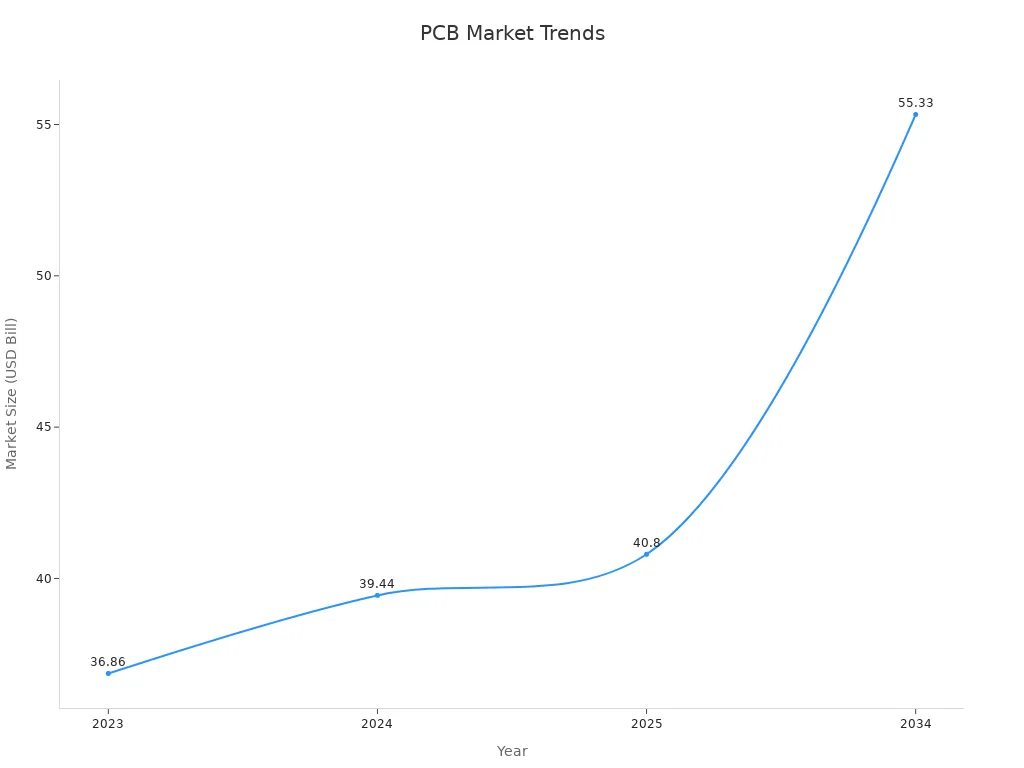

The table below shows how the market is growing:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2023 | 36.86 | N/A |

| 2024 | 39.44 | N/A |

| 2025 | 40.80 | N/A |

| 2034 | 55.33 | 3.44 |

The PCB industry keeps improving. It offers faster, better, and cheaper solutions for today’s electronics.

Top PCB Assembly Manufacturers

TTM Technologies – Skilled in PCB Assembly

TTM Technologies is a top name in PCB assembly. They are experts in making HDI PCBs, especially for aerospace and defense. Their focus on new ideas ensures your products work well and last long.

| Key Services Offered | Industry Focus | Performance Metrics |

|---|---|---|

| HDI PCB manufacturing | Aerospace and Defense | 30% better signal quality for military electronics |

Choosing TTM Technologies means getting advanced solutions. They improve signal quality and help your electronics work perfectly in tough conditions.

Sanmina Corporation – Strong Engineering Skills

Sanmina Corporation is great at advanced PCB assembly. Their engineering skills and creative ideas make them stand out. With $7 billion yearly revenue and $187 million spent on research, they lead in technology.

| Metric | Value |

|---|---|

| Annual Revenue | $7 billion |

| R&D Investment | $187 million |

| New Patent Filings | 42 in 2023 |

| Circuit Board Design Complexity | 9.2/10 |

| Revenue from Medical and Aerospace Sectors | $1.2 billion |

Sanmina focuses on complex designs and works in medical and aerospace fields. They are a great choice for high-tech projects.

Jabil Inc. – All-in-One Electronics Services

Jabil Inc. offers many electronic services, making them a one-stop shop. They work in over 100 locations across 30 countries.

- Jabil’s digital tools improve training and keep workers happy.

- They use AI and automation to grow and improve.

- Happy customers are key to their success.

Working with Jabil gives you access to their smart ideas and experience.

Flex Ltd. – Smart Solutions Worldwide

Flex Ltd. is known for its smart PCB assembly solutions. They use new technology to give you the best service.

| Indicator | Improvement Percentage |

|---|---|

| Line utilization improvement | 20–30% |

| Increase of line operator productivity | ~33% |

| Increase of engineering team productivity | 25–30% |

Flex uses tools like Pulse for supply chain tracking and JRM for risk control. These tools make Flex a top pick for reliable PCB services.

Plexus Corp. – Reliable PCB Assembly Services

Plexus Corp. focuses on giving you high-quality PCB assembly. They listen to your needs and make sure every project is done right. Their attention to detail has made them a trusted name in electronics.

Benchmark Electronics – Full PCB Assembly Services

Benchmark Electronics offers full PCB assembly services for many industries. They are experts in making circuit boards to high standards. Their focus on quality and new ideas makes them a dependable choice.

Creation Technologies – Custom Solutions for Your Needs

Creation Technologies creates custom solutions for your unique projects. They focus on making things scalable and easy to manage. Choosing them means working with a team that understands your goals and delivers great results.

Precision Technologies – Trusted for Quality

Precision Technologies is known for its high-quality PCB assembly. They follow global standards to ensure your products are top-notch.

| Standard | Description |

|---|---|

| IPC-A-610 | Rules for soldering and placing parts correctly. |

| IPC-6012 | Standards for strong and reliable PCBs. |

| IPC-7711/7721 | Guides for fixing and improving PCBs. |

| AS9100/ISO9001 | Quality management standards for better products. |

| IEEE Standards | Rules for designing and testing electronic circuits. |

With Precision Technologies, your PCBs will meet strict quality rules.

Z Axis – Advanced PCB Services

Z Axis provides advanced PCB assembly services. They are skilled in custom designs and fast prototyping.

| Feature | Description |

|---|---|

| Advanced Manufacturing | Uses ISO-9000: 2015 methods for quality. |

| Engineering Expertise | Team with 100+ years of combined experience. |

| Customization | Makes special connectors for unique needs. |

| Consistent Performance | Tests products for quality and reliability. |

| Rapid Prototyping | Quickly makes small or large batches of products. |

| Demanding Tolerances | Custom wire spacing for tight spaces. |

| Application-Specific Solutions | Solves unique problems with small, affordable batches. |

Z Axis focuses on quality and innovation, making them a great choice.

Sierra Circuits – Fast and Reliable Service

Sierra Circuits is known for quick and quality service. If you need PCBs fast, they deliver.

- PCBs can be made in just 24 hours.

- Full boards with parts can be ready in 5 days.

- Their certifications prove their high-quality work.

Sierra Circuits helps you stay on track without losing quality.

How to Pick the Best PCB Assembly Manufacturer

Checking Quality Standards and Certifications

When picking a PCB assembly company, focus on quality first. Certifications like IPC-A-610 and ISO 9001 show they follow strict rules. Automated tests, like AOI and in-circuit testing, find problems early. These steps make sure your products work well and meet industry rules.

Tip: Always ask for proof of their quality checks and certifications. This helps you trust their work and ensures they are reliable.

Looking at Costs and Affordability

Cost is important when choosing a PCB manufacturer. Find one with clear pricing and no hidden fees. Check their minimum order sizes to match your needs. A good partner offers fair prices without lowering quality.

| Factor | What to Look For |

|---|---|

| Pricing Details | Clear costs, small order options, and no extra charges. |

| Value for Money | Affordable prices while keeping high standards. |

Why Delivery Time Matters

Fast delivery is key in today’s tech world. A PCB assembly company with quick lead times helps you launch faster. Short production times improve efficiency and keep you ahead of others.

- Fast deliveries avoid delays in making products.

- Quick lead times help you beat competitors to market.

Note: Pick a company that shares clear schedules and delivers on time.

Customer Service and Communication

Good customer support makes working together easier. A dependable company gives updates, solves problems fast, and works well with you. Studies show quick responses and expert help make customers happier.

| Factor | Importance Level | What It Means |

|---|---|---|

| Customer Support | High | Checks how fast and well they solve issues. |

| Expertise and Responsiveness | High | Shows their ability to keep promises and deliver quality. |

Customization and Growth Options

Your project might need special designs or more production later. A good PCB manufacturer offers custom solutions and can grow with your needs. For example, some focus on small batches for medical devices, while others handle large orders for gadgets.

| Business Type | Need Description | Result |

|---|---|---|

| Electronics Company | Fast production for a new product | Faster launch with a full-service partner. |

| Medical Device Maker | Small batch of special PCBs | Affordable small production with top quality. |

Pro Tip: Share your future plans with the company to ensure they can grow with you.

Picking the right PCB assembly company helps your electronics succeed. Good companies focus on quality, speed, and happy customers. Numbers like high success rates and few returns show their worth.

| Metric | Why It Matters |

|---|---|

| Industry Certifications | Shows they follow global rules for safety and quality. |

| First-pass Yield Rate | Proves they make products well without many mistakes. |

| Customer Return Rate | Tells how reliable their products are and if buyers are happy. |

Check these points to find a company that fits your needs.

FAQ

What certifications should a PCB assembly manufacturer have?

Check for ISO 9001, IPC-A-610, and AS9100 certifications. These show the manufacturer meets strict quality rules and makes reliable products.

Tip: Always check their certifications before working with them.

How can I make sure my PCB design works with the manufacturer?

Send your Gerber files and design details early. Request a DFM (Design for Manufacturability) review to spot problems before production starts.

How long does PCB assembly usually take?

The time depends on how complex it is. Regular assemblies take 2–4 weeks. Fast services can finish in just 24 hours.

Note: Ask about timelines during your first meeting to avoid delays.