When it comes to creating electronic devices, two critical processes come into play: PCB fabrication and PCB assembly. PCB fabrication involves building the physical structure of a printed circuit board, including layers like copper for conductivity and fiberglass for support. On the other hand, PCB assembly focuses on attaching electronic components to the fabricated board, transforming it into a functional unit.

The global PCB assembly market, valued at over USD 90 billion in 2023, is growing at a steady 5% CAGR, reflecting its importance in modern electronics. Similarly, the PCB market is projected to rise from $75 billion in 2021 to $120 billion by 2030. These figures highlight the increasing demand for both processes, which serve as the backbone of technological innovation.

Key Takeaways

- PCB fabrication builds the board’s structure, while assembly adds parts to make it work.

- Careful work in fabrication and assembly is key for reliable devices.

- Picking fabrication or assembly depends on your project: fabrication for design, assembly for working devices.

- Using machines in assembly makes it faster and better, meeting industry rules.

- Knowing how fabrication and assembly differ helps improve electronics production.

PCB Fabrication

What is PCB Fabrication?

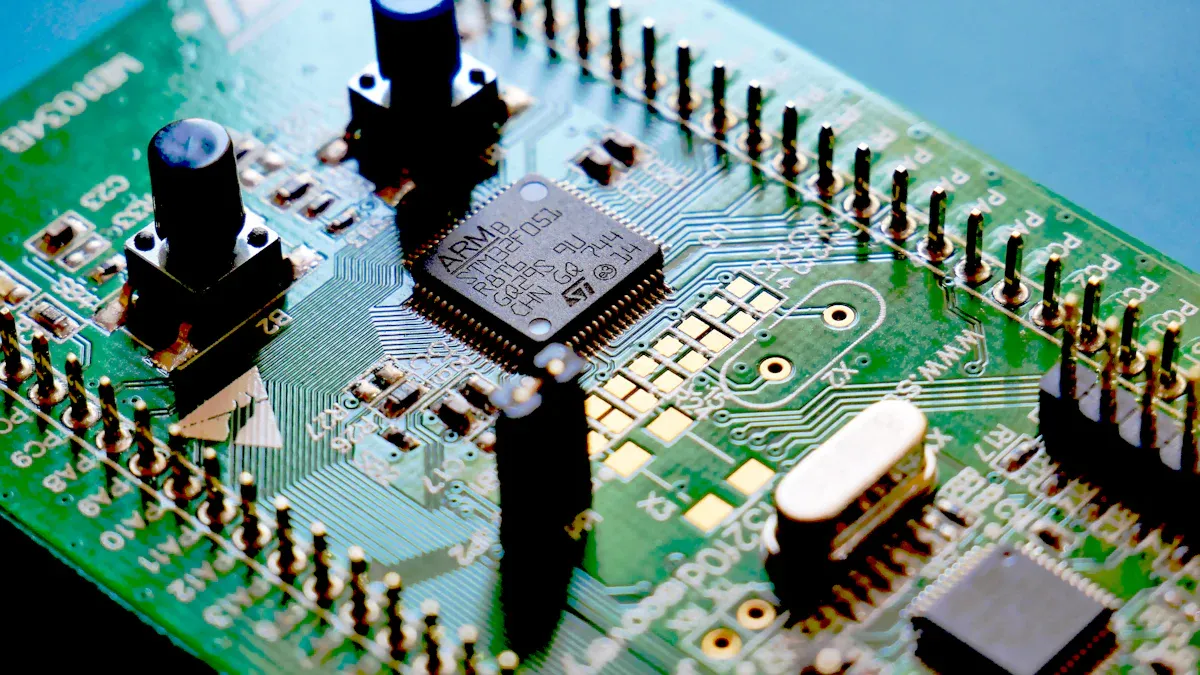

PCB fabrication is the process of creating the physical structure of a printed circuit board. It involves transforming raw materials into a functional base that supports electronic components. You start with a non-conductive substrate layered with copper, which forms the conductive pathways. This process ensures the board is ready for assembly, where components are added to make it operational. Without proper fabrication, achieving a reliable and durable PCB becomes impossible.

Key Steps in PCB Fabrication

Designing the PCB Layout

The first step in fabrication is designing the PCB layout. You use specialized software to create a blueprint that defines the placement of components and conductive pathways. This design ensures the board meets your specific requirements.

Creating PCB Layers

Next, the board’s layers are prepared. A laminate with a copper layer is used as the base. This step forms the foundation for the conductive traces that will carry electrical signals.

Etching and Adding Copper Traces

Etching removes excess copper, leaving behind the desired circuit pattern. This step is crucial for defining the pathways that connect components. You achieve this by transferring the design onto the board using a photosensitive film and UV light.

Drilling Holes and Adding Vias

Holes are drilled to allow for component mounting and interconnections between layers. Vias, or plated holes, ensure electrical continuity across multiple layers.

Applying Solder Mask and Silkscreen

A solder mask is applied to protect the board from oxidation and prevent solder bridges. Finally, silkscreen printing adds essential information, such as component labels, to guide assembly.

Tip: Ensuring precision at each step minimizes errors and enhances the board’s reliability.

Applications of PCB Fabrication

PCB fabrication plays a vital role in various industries:

- Medical: Used in imaging equipment and implantable devices.

- Automotive: Found in onboard computers for safety and entertainment systems.

- Telecommunications: Essential for high-frequency amplifiers and LED displays.

- Military & Defense: Critical for secure and reliable systems in vehicles and networks.

- Consumer Electronics: Integral to smartphones, laptops, and other devices.

The automotive sector alone is driving significant growth, with the PCB market expected to reach $13.39 billion by 2030. This highlights the importance of fabrication in advancing technology across industries.

PCB Assembly

What is PCB Assembly?

PCB assembly is the process of transforming a bare printed circuit board into a functional unit by attaching electronic components. This step is essential for creating devices that power modern technology. By using advanced techniques and equipment, you can ensure that each component is placed accurately and securely on the board. The pcb assembly process bridges the gap between design and functionality, making it a cornerstone of electronics manufacturing.

Key Steps in PCB Assembly

Solder Paste Application

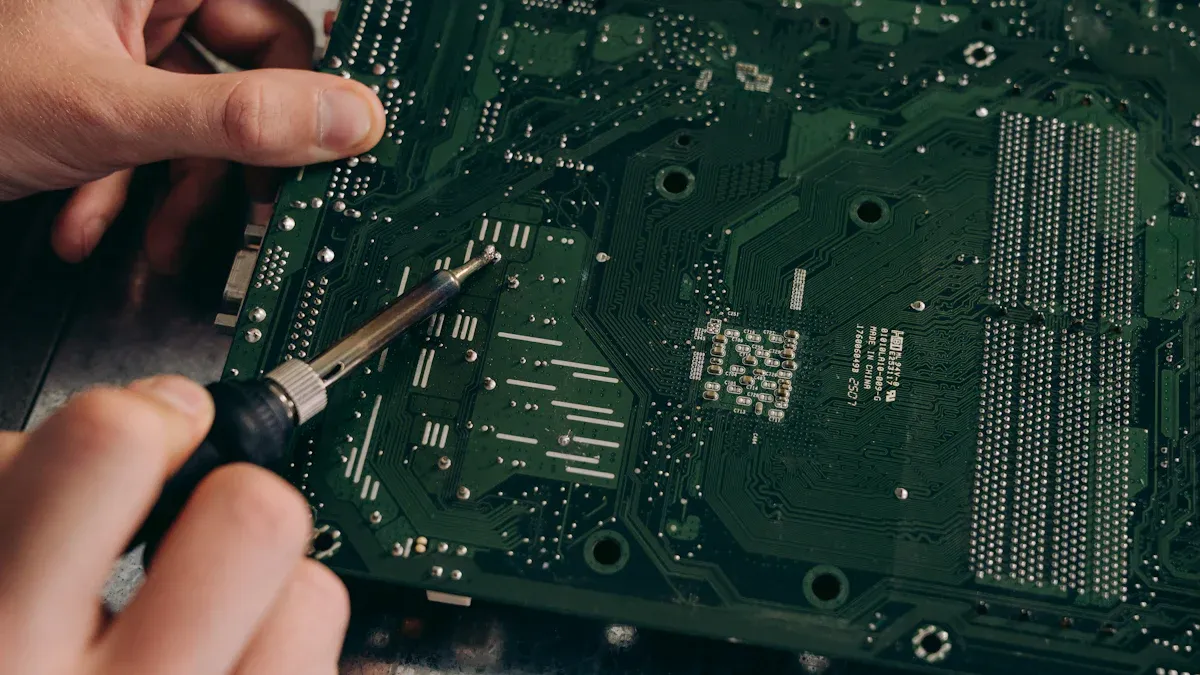

The process begins with applying solder paste to the board. This paste, a mixture of powdered solder and flux, is applied to the pads where components will be mounted. Precision is critical here, as uneven application can lead to defects during soldering.

Component Placement

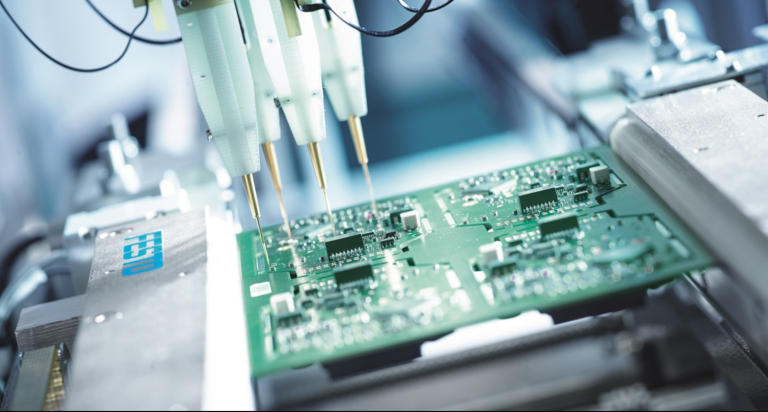

Next, components are placed onto the board. Automated pick-and-place machines handle this step with incredible speed and accuracy. These machines ensure that each component aligns perfectly with its designated pad, reducing the risk of misalignment.

Soldering Techniques (SMT and Through-Hole)

Soldering secures the components to the board. Two primary techniques are used:

- SMT (Surface Mount Technology): Components are mounted directly onto the PCB surface. This method supports high-density designs and reduces weight.

- THT (Through-Hole Technology): Components are inserted into drilled holes and soldered. This technique offers stronger mechanical bonds, making it ideal for high-stress applications like automotive and aerospace.

Inspection and Testing

Quality control ensures the reliability of the circuit board assembly. Common inspection methods include:

- Automated Optical Inspection (AOI): Detects defects in solder joints and component placement.

- X-Ray Inspection: Identifies hidden issues like solder shorts.

- In-Circuit Testing (ICT): Verifies the functionality of individual components.

These steps help you deliver high-quality products with minimal defects.

Applications of PCB Assembly

PCB assembly plays a vital role in various industries:

- Consumer Electronics: Found in smartphones, laptops, and gaming consoles.

- Medical Devices: Used in imaging equipment and wearable health monitors.

- Automotive: Powers advanced driver-assistance systems and infotainment units.

- Industrial Equipment: Supports automation and control systems.

From home appliances to cutting-edge medical devices, printed circuit board assembly drives innovation across sectors.

Tip: Automating the pcb assembly process enhances speed, consistency, and product quality, giving you a competitive edge.

Key Differences Between PCB and PCBA

Purpose

Understanding the purpose of PCB fabrication and PCB assembly helps you grasp their distinct roles in electronics manufacturing.

- PCB fabrication focuses on creating the bare printed circuit board. This involves etching conductive pathways, adding insulating layers, and preparing the board for further processing.

- PCB assembly, on the other hand, transforms the bare board into a functional unit. By soldering components onto the board, you enable it to perform specific tasks in electronic devices.

- The end goal of PCB fabrication is to establish the foundational structure of the PCB.

- The end goal of PCB assembly is to integrate components that make the PCB operational.

Note: The relationship between PCB and PCBA is sequential. Without a fabricated PCB, you cannot proceed to assembly.

Processes

The processes involved in PCB fabrication and assembly differ significantly.

- PCB Fabrication:

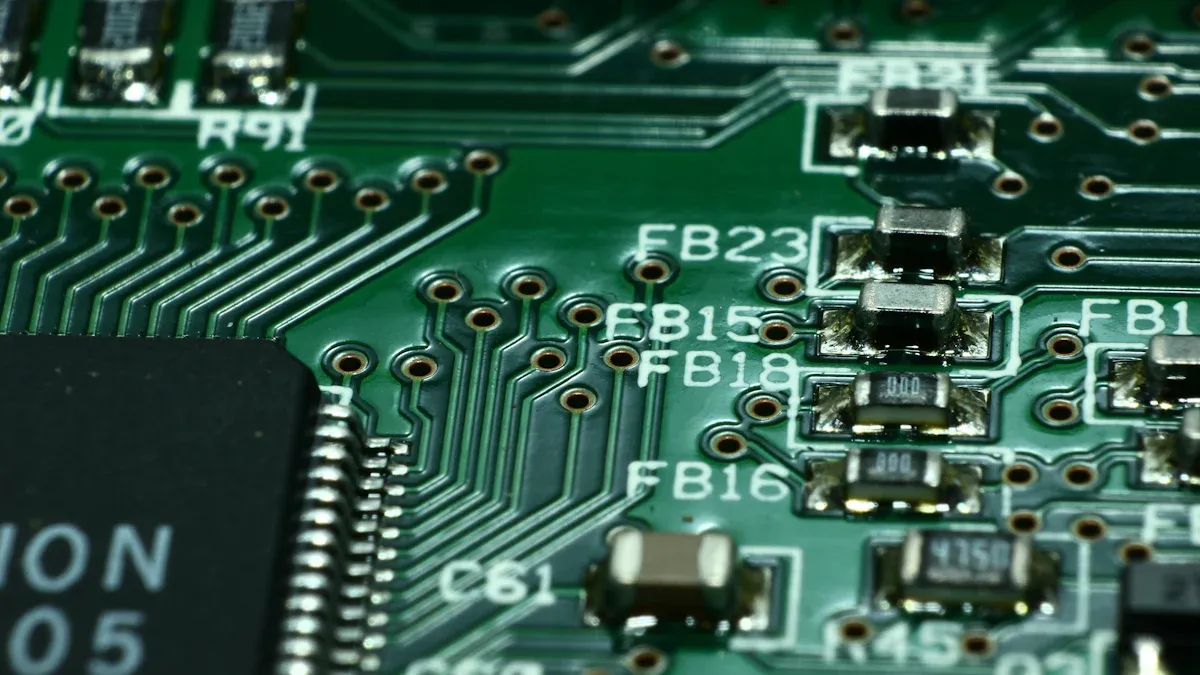

- Patterning and etching define the conductive pathways.

- Drilling creates holes for interconnections.

- Lamination and plating add durability and conductivity.

- Solder mask and silkscreen application protect the board and provide labeling.

- PCB Assembly:

- Solder paste application prepares the board for component placement.

- Automated pick-and-place machines ensure precise component alignment.

- Advanced soldering techniques, like selective soldering, secure components.

- Inspection and testing verify the functionality of the printed circuit board assembly.

Each step in these processes requires specialized tools and technologies, such as copper cladding and photoengraving for fabrication or soldering and testing equipment for assembly.

Applications

The applications of PCB fabrication and assembly cater to different needs across industries.

| Industry | PCB Fabrication Needs | PCB Assembly Needs |

|---|---|---|

| Medical | High-density interconnects, flex PCBs | Precision assembly for diagnostic devices |

| Automotive | Reliable, lightweight designs | Functional control systems |

| Military & Defense | Secure, durable PCBs | Mission-critical system assembly |

| Telecommunications | Signal processing, network reliability | Functional network equipment |

PCB fabrication produces blank boards tailored to industry-specific requirements. PCB assembly integrates components to create functional devices, such as smartphones, medical monitors, or automotive control units.

When deciding how to choose between PCB and PCBA, consider your project’s stage. If you need a foundational board, opt for fabrication. If you require a functional device, assembly is the way forward.

When to Choose PCB Fabrication or Assembly

Scenarios for Choosing PCB Fabrication

When custom-designed PCBs are required.

If your project demands a unique design, PCB fabrication is the way to go. Custom-designed PCBs allow you to tailor the board’s layout, size, and functionality to meet specific requirements. This is especially important in industries like medical devices or automotive systems, where precision and reliability are critical. A fabricated PCB serves as the foundation for your device, ensuring it meets your exact specifications. By starting with a custom design, you can avoid compatibility issues during the assembly phase.

When prototyping or mass-producing blank boards.

Prototyping is essential when you want to test your design before committing to mass production. It helps you identify faults, verify performance, and explore cost-effective manufacturing methods. For instance, prototyping allows you to inspect individual components and test the board in various environments, ensuring reliability. Once the design is finalized, you can scale up to mass production. Fabricating blank boards in bulk reduces costs as the setup expenses are distributed across a larger quantity. This approach is ideal for industries requiring high volumes of PCBs, such as telecommunications or consumer electronics.

Tip: Prototyping not only saves money but also minimizes risks by catching errors early in the process.

Scenarios for Choosing PCB Assembly

When fully functional electronic devices are needed.

PCB assembly is your go-to solution when you need a functional device. By attaching components to the fabricated board, you transform it into a working unit. This process is crucial for creating products like smartphones, medical monitors, or automotive control systems. Advanced pcb assembly methods, such as SMT and THT, ensure precision and reliability. These techniques allow you to meet the high standards required in industries like aerospace or defense.

When integrating components into pre-fabricated PCBs.

If you already have fabricated boards, assembly is the next step. This scenario is common when you outsource fabrication but handle assembly in-house or vice versa. By integrating components into pre-fabricated PCBs, you can focus on optimizing functionality. Automated processes like pick-and-place machines and AOI inspections enhance speed and accuracy, ensuring high-quality results. This approach is particularly beneficial when you need to meet tight deadlines or produce complex devices.

Note: Understanding how to choose a pcb assembly manufacturer can significantly impact the quality and cost of your project. Look for a partner with expertise in both fabrication and assembly to streamline the process.

Understanding the differences between PCB fabrication and assembly helps you make informed decisions for your projects. Fabrication focuses on creating the physical board, while assembly transforms it into a functional unit by adding components. Each process plays a unique role in electronics manufacturing.

When deciding between the two, consider key factors like quality, time, and cost. For instance, if you need a custom design or blank boards for prototyping, fabrication is the right choice. On the other hand, assembly is ideal when you require fully functional devices or need to integrate components into pre-fabricated boards.

Pro Tip: Stay ahead of the curve by exploring trends like HDI miniaturization, AI-driven automation, and sustainable manufacturing practices. These innovations can enhance your pcb production and assembly processes, ensuring efficiency and eco-friendliness.

FAQ

What is the difference between PCB fabrication and PCB assembly?

PCB fabrication creates the physical board, including layers and conductive pathways. PCB assembly adds components to make the board functional. Think of fabrication as building the foundation and assembly as completing the structure. Both are essential for creating reliable electronic devices.

Tip: Start with fabrication if you need a blank board. Choose assembly for a functional product.

How do you ensure quality in PCB assembly?

You ensure quality by using automated processes like pick-and-place machines and inspection methods such as AOI and X-ray. These steps detect defects early and improve reliability. Partnering with experienced manufacturers also guarantees high standards.

Pro Tip: Always verify the manufacturer’s expertise in both fabrication and assembly.

Can you use the same manufacturer for both PCB fabrication and assembly?

Yes, many manufacturers offer both services. This approach saves time and ensures compatibility between the fabricated board and assembled components. It also simplifies communication and reduces the risk of errors.

Emoji Insight: ✅ Opt for a one-stop solution to streamline your project.

What industries benefit most from PCB assembly?

Industries like consumer electronics, automotive, medical, and telecommunications rely heavily on PCB assembly. It powers devices like smartphones, medical monitors, and automotive control systems. Assembly ensures these products meet performance and reliability standards.

Note: PCB assembly drives innovation across multiple sectors.

How do you choose the right PCB assembly manufacturer?

Look for a manufacturer with advanced equipment, quality certifications, and a proven track record. Check their expertise in SMT and THT techniques. A reliable partner ensures precision, speed, and cost-effectiveness.

Call to Action: 🛠️ Choose KING FIELD for expert PCB assembly solutions tailored to your needs.