Choosing a PCB manufacturer is a critical decision that directly impacts the success of your electronic projects. An unreliable partner can lead to design flaws, material inconsistencies, or manufacturing defects, jeopardizing your product’s performance. KING FIELD eliminates these risks with over 20 years of expertise, advanced technology, and a trusted PCB manufacturing plant that delivers precision and quality every time.

Key Takeaways

- Pick a PCB maker with lots of experience. KING FIELD has worked for over 20 years, giving your projects expert support.

- Check for modern manufacturing tools. KING FIELD uses the latest tech to make accurate and top-quality PCBs for today’s designs.

- Make sure the maker follows quality rules. KING FIELD has ISO certifications, proving their products are safe and trustworthy.

Expertise and Manufacturing Capabilities

KING FIELD’s Experience in the Industry

When choosing a PCB manufacturer, you need a partner with proven experience and expertise. KING FIELD has over 20 years of industry leadership, making it a trusted name in PCB manufacturing. This extensive experience ensures that your projects benefit from a deep understanding of industry trends and challenges. KING FIELD’s ability to handle complex requirements, from multilayer PCBs to high-density interconnect (HDI) boards, demonstrates its unmatched expertise. By partnering with KING FIELD, you gain access to a team that transforms your ideas into reliable, high-quality products.

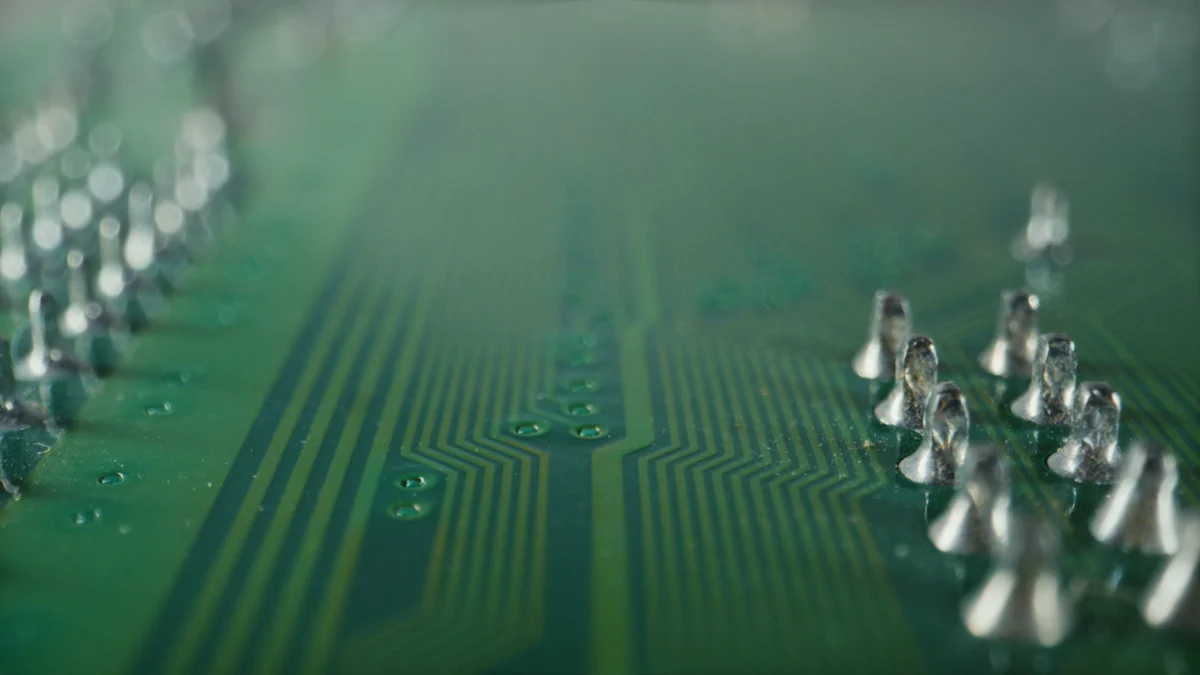

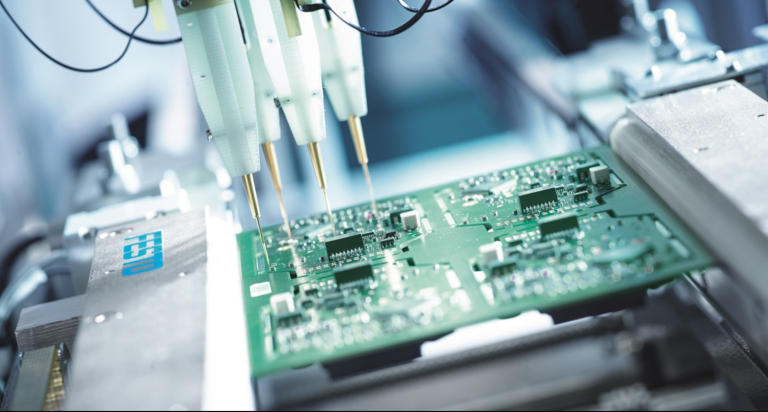

Advanced Manufacturing Capabilities and Technology

KING FIELD leverages cutting-edge manufacturing capabilities and technology to deliver precision and efficiency. The use of advanced techniques like Laser Direct Imaging (LDI) ensures accurate circuit trace outlining, while High-Density Interconnect (HDI) technology allows for compact designs ideal for modern devices. KING FIELD also excels in producing flexible and rigid-flex PCBs, which are lightweight and adaptable for industries like medical and automotive. By adopting environmentally friendly materials and finishes, KING FIELD not only meets regulatory standards but also supports sustainable manufacturing. These advancements ensure that your products are built to the highest standards of quality and innovation.

Comprehensive Services Offered by KING FIELD

KING FIELD offers a one-stop solution for all your PCB needs. From design and development to manufacturing and assembly, every step is handled with precision. The company’s services include electronic product design, PCB fabrication, component sourcing, and final assembly. This comprehensive approach eliminates the need to coordinate with multiple vendors, saving you time and reducing costs. KING FIELD’s global supply chain network ensures quick responses to market demands, helping you bring your products to market faster. By choosing KING FIELD, you secure a reliable partner dedicated to your success.

Quality Standards and Certifications

Importance of Industry Certifications (e.g., ISO, IPC)

When choosing a PCB manufacturer, you need to ensure they meet recognized quality standards and certifications. These certifications demonstrate a manufacturer’s commitment to delivering reliable and high-quality products. For example:

| Certification | Description | Importance |

|---|---|---|

| ISO 9001:2015 | Basic quality management system certification. | Ensures consistent quality management practices. |

| ISO 13485 | Focuses on manufacturing processes of PCB assembly. | Guarantees strict process control, especially for medical devices. |

| UL Certification | Globally recognized for assessing hardware and software capabilities. | Builds trust with customers and ensures product safety. |

Certifications like these are essential for competing in today’s market. They assure you that the manufacturer follows industry best practices, resulting in fewer defects and higher reliability.

KING FIELD’s Commitment to Quality Standards and Certifications

KING FIELD prioritizes quality standards and certifications to deliver exceptional results. The company holds ISO certifications, including ISO 9001 and ISO 13485, which reflect its dedication to quality management and process control. KING FIELD also complies with IPC-A-600 standards, ensuring every PCB meets stringent quality benchmarks. By choosing KING FIELD, you gain a partner that values precision and reliability, giving you peace of mind for your projects.

Regulatory Compliance and Environmental Responsibility

KING FIELD goes beyond standard certifications by adhering to global regulatory requirements. The company uses environmentally friendly materials and processes to minimize its ecological footprint. This commitment not only ensures compliance with environmental regulations but also supports sustainable manufacturing. When you work with KING FIELD, you align with a PCB manufacturer that values both quality and environmental responsibility.

Ensuring Product Quality

Material Sourcing and Quality Control

The foundation of exceptional PCBs lies in the materials used. KING FIELD ensures that every component meets stringent quality standards. By sourcing materials from trusted suppliers, the company guarantees durability and reliability. A robust quality management system monitors every stage of production, ensuring consistency. Techniques like Statistical Process Control (SPC) and Six Sigma methodologies further enhance precision. These practices minimize defects and ensure your PCBs meet the highest standards. When choosing a PCB manufacturer, you need one that prioritizes material integrity, and KING FIELD delivers exactly that.

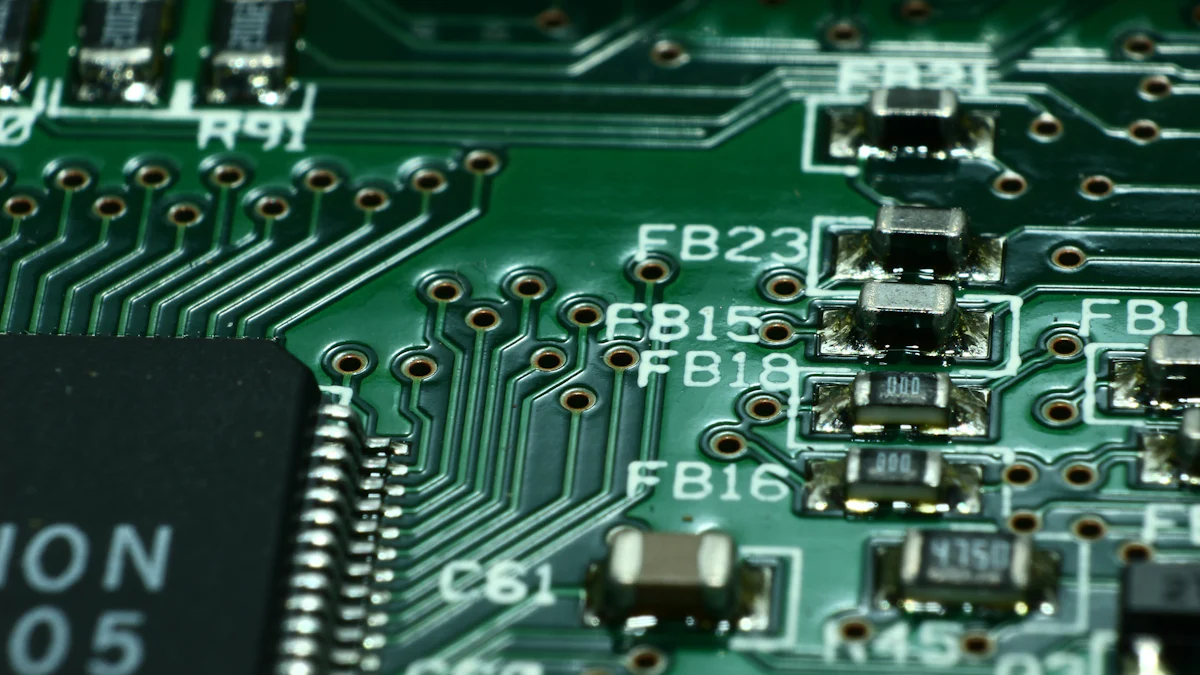

Testing and Quality Assurance Processes at KING FIELD

Testing is critical to maintaining product quality. KING FIELD employs advanced methods to ensure flawless performance. Automated Optical Inspection (AOI) detects surface defects, while X-ray inspection examines hidden solder joints in Ball Grid Array (BGA) and Chip-Scale Package (CSP) components. In-Circuit Testing (ICT) verifies the functionality of individual components, and Environmental Stress Screening (ESS) exposes PCBs to extreme conditions to uncover latent defects. Functional testing simulates real-world scenarios, ensuring your PCB performs as intended. These rigorous processes reflect KING FIELD’s commitment to high-quality manufacturing.

Proven Track Record of Delivering High-Quality PCBs

KING FIELD’s reputation speaks for itself. With over 20 years of experience, the company has consistently delivered reliable PCBs across industries like medical, automotive, and consumer electronics. Its focus on product quality and innovation has earned the trust of clients worldwide. By partnering with KING FIELD, you gain access to a proven leader in PCB manufacturing. This track record ensures your projects succeed, giving you confidence in every product delivered.

Delivery and Lead Times

Efficient Production Timelines at KING FIELD

When choosing a PCB manufacturer, you need a partner that values your time. KING FIELD excels in delivering PCBs within industry-standard timelines, ensuring your projects stay on track. The average lead time for PCB production varies by complexity:

| Complexity Level | Lead Time Range |

|---|---|

| Simple, low-volume PCBs | 1-2 weeks |

| Moderate complexity, medium volume | 2-4 weeks |

| High complexity or high volume | 4-8 weeks or more |

KING FIELD’s advanced manufacturing capabilities and streamlined processes allow it to meet or even exceed these benchmarks. By optimizing production workflows and leveraging cutting-edge technology, KING FIELD ensures on-time delivery without compromising quality.

Flexibility in Meeting Tight Deadlines

Unexpected challenges can arise during product development, but KING FIELD’s flexibility ensures your deadlines are met. Whether you need a quick turnaround for a prototype or a large-scale production run, KING FIELD adapts to your requirements. The company’s robust capacity planning and global supply chain network enable it to handle urgent orders efficiently. This flexibility minimizes delays and helps you bring your products to market faster.

Transparency in Delivery Schedules

Clear communication is essential for managing expectations. KING FIELD provides complete transparency in delivery time, keeping you informed at every stage of the process. Factors like design complexity, material availability, and logistics challenges can impact timelines. KING FIELD mitigates these risks through:

- Early supplier engagement

- Streamlined quality control processes

- Proactive regulatory compliance

- Optimized logistics

By choosing KING FIELD, you gain a partner committed to delivering your PCBs on time and at affordable prices. The company’s focus on location and shipping options ensures your products reach you efficiently, no matter where you are.

Cost and Value

Balancing Cost with Quality

When selecting a PCB manufacturer, you must balance cost with quality to ensure your investment delivers value. The cost of pcb manufacturing varies widely based on complexity and materials. For instance:

- A simple single-layer PCB may cost just a few dollars.

- Complex multi-layer boards can range from $100 to $500 or more.

- Specialty materials like Rogers demand higher prices compared to standard options like FR-4.

KING FIELD helps you strike this balance by offering high-quality PCBs at competitive prices. With advanced manufacturing techniques and efficient processes, KING FIELD ensures you receive durable, reliable products without overspending. By choosing KING FIELD, you avoid compromising on quality while staying within budget.

Transparent Pricing Structures at KING FIELD

Transparency in pricing is essential for building trust. KING FIELD provides clear and upfront pricing, so you know exactly what you’re paying for. The company’s pricing structure reflects the complexity of your design, material selection, and production volume. Larger orders benefit from economies of scale, reducing the cost per unit. KING FIELD’s commitment to transparency eliminates surprises, allowing you to plan your project confidently. With KING FIELD, you gain a partner that values honesty and ensures every dollar you spend contributes to your success.

Avoiding Hidden Costs in PCB Manufacturing

Hidden costs can derail your budget and delay your project. KING FIELD eliminates these risks by addressing common cost factors upfront, such as:

- Prototyping and testing to meet design specifications.

- Tooling and manufacturing for custom PCBs.

- Assembly and testing to ensure functionality.

- Quality control and certifications to meet industry standards.

- Shipping and logistics for timely delivery.

By managing these aspects efficiently, KING FIELD ensures you avoid unexpected expenses. This proactive approach saves you time and money, making KING FIELD the ideal choice for your PCB manufacturing needs.

Customer Support and Communication

KING FIELD’s Customer-Centric Approach

Exceptional customer service and support set KING FIELD apart in the PCB manufacturing industry. The company prioritizes customer satisfaction by offering a seamless experience from the initial consultation to post-production assistance. You can rely on their 24/7 availability to address concerns promptly, ensuring minimal downtime during critical stages of your project. Their multi-channel support system, including email, phone, and live chat, provides flexibility and convenience. With a team of experts ready to assist, KING FIELD ensures your requirements are met with precision and care. By choosing KING FIELD, you establish clear communication with a partner dedicated to your success.

| Feature | Description | Why It’s Important |

|---|---|---|

| 24/7 Availability | Support available at all hours to address issues promptly. | Minimizes downtime and ensures quick resolutions. |

| Technical Expertise | Knowledgeable staff who understand PCB intricacies. | Provides accurate solutions tailored to your project. |

| Multi-Channel Support | Access via email, phone, live chat, and ticketing systems. | Offers convenience and efficient problem resolution. |

Technical Support and Problem-Solving Expertise

KING FIELD goes beyond manufacturing by acting as your collaborator. Their technical support team ensures your electronic projects succeed by providing guidance from design to final production. Whether you need help to provide detailed specifications and documentation or resolve complex issues, their experts deliver accurate solutions. This proactive approach guarantees quality and reliability, even in time-sensitive environments. With KING FIELD, you gain a partner that helps you overcome challenges and achieve your goals.

Post-Sales Service and Long-Term Partnerships

KING FIELD’s commitment doesn’t end with delivery. Their post-sales service ensures your products perform as expected, offering ongoing support to address any concerns. They help you establish clear communication channels for future projects, fostering long-term partnerships. By choosing KING FIELD, you secure a reliable partner who values your success and continuously works to exceed your expectations.

Choosing the right PCB manufacturer is crucial for your project’s success. You need a partner with proven expertise, certified quality standards, efficient delivery, and transparent pricing. KING FIELD excels in all these areas, offering advanced production capabilities, rigorous material selection, and unmatched customer support.

By partnering with KING FIELD, you gain long-term benefits like faster turnaround times, supply chain stability, and tailored solutions for your unique needs. Their commitment to reliability and innovation ensures your products meet the highest standards. Prioritize quality and trust KING FIELD to bring your ideas to life.

FAQ

What makes KING FIELD stand out as a PCB supplier?

KING FIELD combines over 20 years of expertise, advanced technology, and a customer-centric approach to deliver high-quality PCBs tailored to your needs.

How does KING FIELD ensure the quality of its PCBs?

KING FIELD uses rigorous testing, certified materials, and advanced manufacturing processes to guarantee exceptional quality in every product.

Can KING FIELD handle urgent PCB orders?

Yes, KING FIELD’s flexible production capabilities and global supply chain allow it to meet tight deadlines without compromising quality.