Surface mount technology (SMT) has transformed how PCBs are produced, making it essential for creating smaller, faster, and better devices. This is particularly significant for a pcb assembly pcba manufacturer.

- The SMT market is projected to grow from $5.8 billion in 2023 to $8.4 billion by 2028, reflecting a 7.8% annual growth rate.

- This expansion is fueled by the demand for smaller designs, automation, and advanced PCBs with increased connectivity.

Utilizing SMT enables a pcb assembly pcba manufacturer to meet these evolving needs and maintain a competitive edge in electronics manufacturing.

Key Takeaways

- SMT is important for today’s electronics. It helps make smaller, faster, and better devices.

- Using machines in SMT assembly lowers mistakes and makes things faster. This saves money when making many products.

- SMT works for many uses, like gadgets and medical tools. It makes them work better and last longer.

Understanding Surface Mount Technology in PCB Assembly

What is surface mount technology?

Surface mount technology (SMT) is a way to attach electronic parts directly onto a printed circuit board (PCB). Unlike older methods that need holes drilled into the PCB, SMT skips this step. This makes the process faster and more efficient. It is now a key part of making modern electronics because it helps create smaller and better designs.

SMT helps make devices smaller by using tiny components. These parts are about one-tenth the size of older ones. This smaller size has changed industries like electronics, cars, and airplanes, where saving space and weight is very important.

How SMT assembly technology works

SMT assembly uses machines to make the process fast and accurate. First, solder paste is spread on the PCB using a stencil. This shows where the parts will go. Then, a pick-and-place machine puts the parts on the board with great precision. These machines can place thousands of parts every hour.

After the parts are placed, the PCB is heated in a reflow oven. The heat melts the solder paste, connecting the parts to the board securely. This process ensures strong connections and reduces the chance of errors. In fact, SMT has a very low failure rate, less than 10 parts per million.

Using machines for SMT assembly lowers mistakes and speeds up production. It also allows for more parts to fit on smaller boards, which is important for advanced, compact devices.

Key components in SMT PCB assembly

Several important parts are used in SMT PCB assembly:

- Surface-mount devices (SMDs): These are small electronic parts like resistors, capacitors, and chips made for SMT. They are lighter and smaller than older parts.

- Solder paste: This sticky mixture helps connect the parts to the PCB.

- Pick-and-place machines: These machines carefully place parts on the PCB quickly and accurately.

- Reflow ovens: These ovens heat the PCB to melt the solder paste, creating strong connections.

SMT has greatly improved electronics manufacturing. It can reduce the size of devices by 40% to 60% and their weight by 60% to 80%. It also supports faster operating speeds, up to 3000MHz, compared to 500MHz with older methods. These features make SMT essential for today’s technology.

Tip: Using SMT can improve your products’ performance and reliability while cutting costs.

Advantages of SMT Assembly Technology for PCBA Manufacturers

Automation and production efficiency

Automation in surface-mount technology (SMT) has changed how PCBs are made. Using advanced machines makes work faster, reduces mistakes, and improves production. Here’s how automation helps:

- Simpler designs: Better PCB layouts make placing parts easier.

- Less waste: Removing unnecessary steps makes work smoother.

- Quick setup: Machines are ready faster during product changes.

- Faster processes: Doing tasks at the same time saves time.

- Automatic checks: Machines find defects quickly, improving quality.

- Data tracking: Checking data helps fix problems and improve speed.

- Fast part placement: Machines place parts quickly and accurately.

- Smart feeders: Automatic setups save time during changes.

- Precise printers: Solder paste is applied evenly for strong connections.

- Organized storage: Better material handling saves time and avoids errors.

These tools make production faster and better, making SMT vital for modern PCB assembly.

Compact designs with higher component density

SMT helps create smaller designs with more parts on the PCB. It skips drilling holes, letting parts sit directly on the board. This brings many benefits:

- More parts per board: Both sides of the PCB can hold parts.

- Smaller devices: Products like phones and tablets can be thinner.

- Better performance: Shorter paths improve signals and speed.

- Faster assembly: Machines work quickly and reduce human mistakes.

With SMT, you can make smaller, lighter, and stronger devices for today’s needs.

Cost-effectiveness and scalability in pcb assembly

SMT is cost-friendly and works well for large-scale PCB production. Its automated process handles many PCBs quickly, saving money. Here’s how SMT lowers costs:

- Large-scale production: Machines work fast, cutting labor costs and boosting output.

- Mixed methods: Use machines for simple tasks and people for tricky ones to save money.

By using SMT, manufacturers can grow their business and keep prices low. This makes it a smart choice for balancing quality and cost.

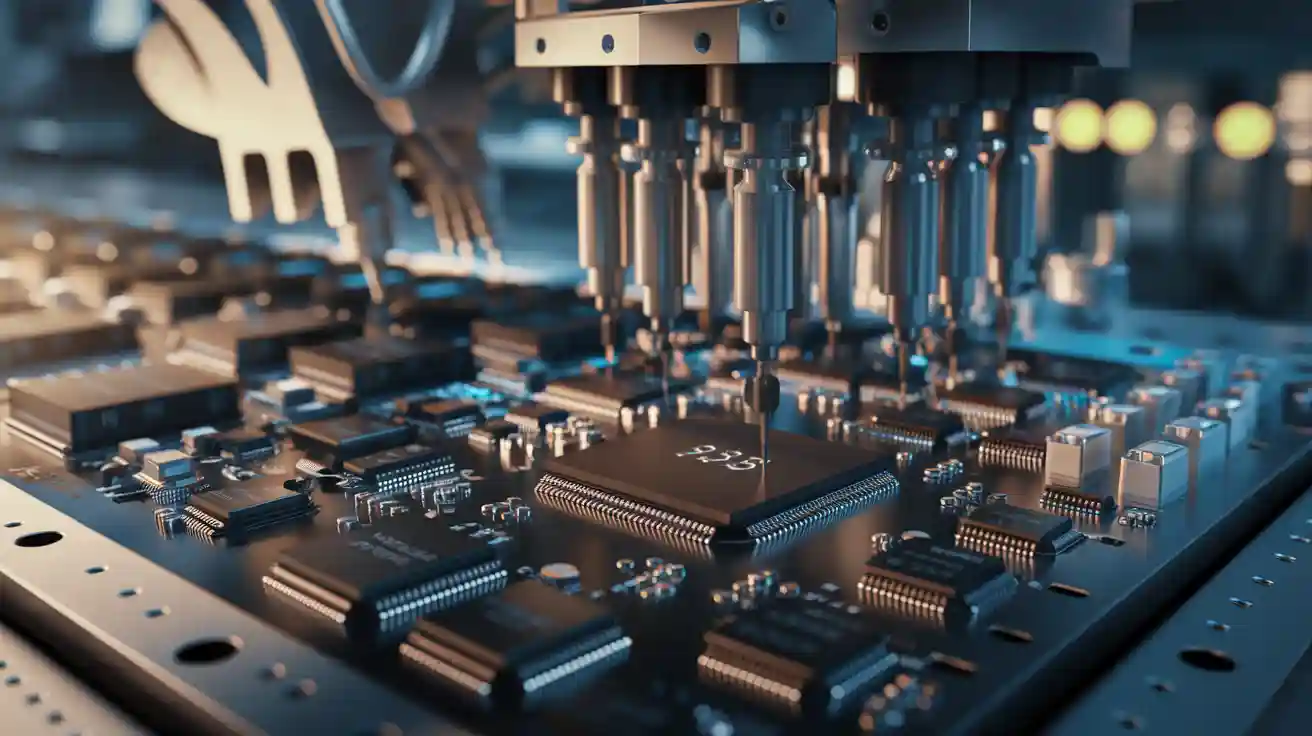

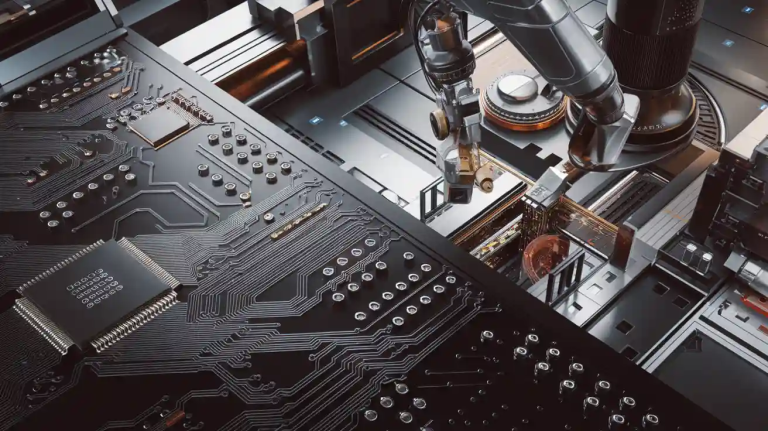

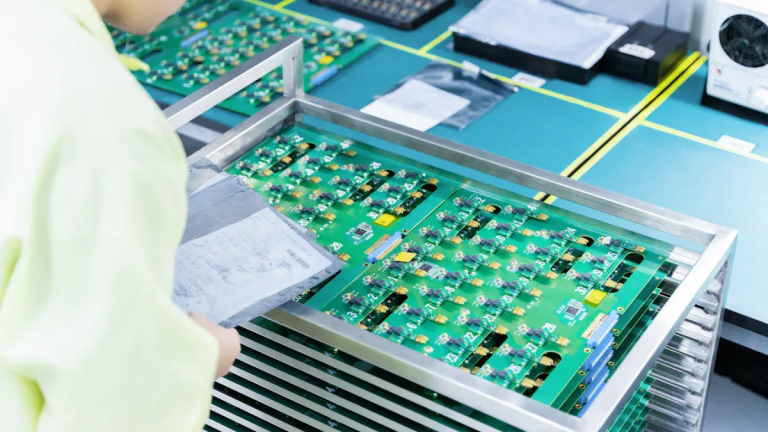

Image: Automated SMT assembly line with fast machines and smart tools.

Comparing SMT and Through-Hole Technologies

Differences between surface-mount technology and through-hole

Surface Mount Technology (SMT) and Through-Hole Technology (THT) are very different. SMT parts are tiny and light, fitting more on a PCB. They stick directly to the board without needing holes, making assembly quicker and cheaper. THT parts need holes, which makes them stronger but slower to assemble.

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Smaller | Larger |

| Component Density | Higher | Lower |

| Assembly Time | Faster | Slower |

| Cost-Effectiveness | More efficient | Less efficient |

| Physical Connection | Weaker | Stronger |

SMT works best for small designs and automated processes. THT is better for tough jobs where strength matters.

Why SMT is the preferred choice for modern applications

SMT is popular in electronics because it’s fast and flexible. It helps make smaller, lighter, and faster devices, which are in high demand. Today, over 90% of PCBs use SMT because it’s so useful.

- SMT fits more parts on a PCB, making it work better.

- Machines assemble SMT quickly, saving time and money.

- Tiny parts allow for slim designs like phones and tablets.

SMT is perfect for making lots of products quickly and efficiently.

When through-hole technology is still relevant

Through-hole technology is still important for certain industries. Its strong connections and heat resistance make it great for military, space, and heavy-duty uses. THT is also easier to test and fix, making it good for small projects.

- THT is best for high-power devices needing strong connections.

- It works well for products facing heat or vibration.

Even though SMT is common, THT is still needed for jobs where strength and reliability are key.

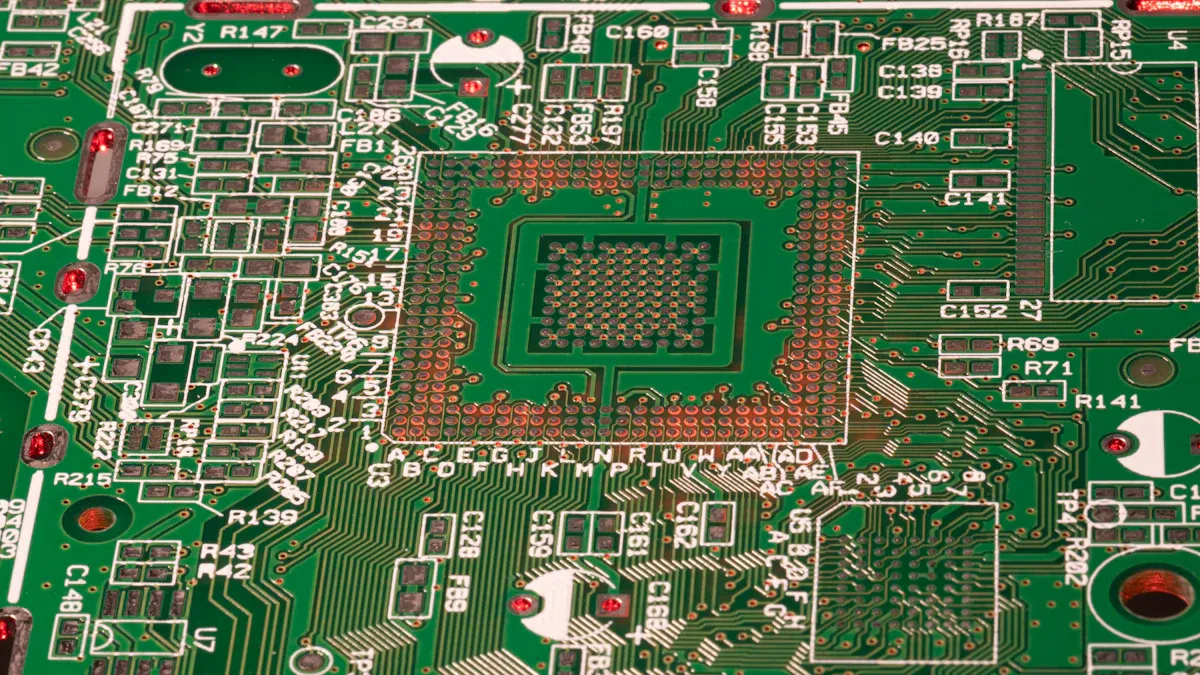

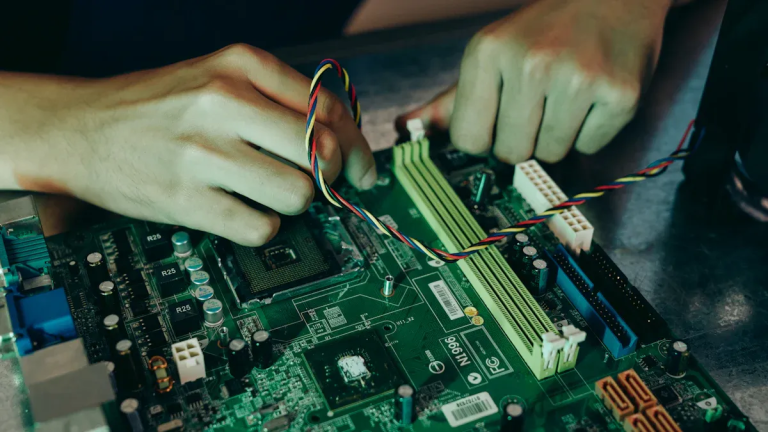

Image: SMT and THT components side by side on a PCB.

Applications of SMT PCB Assembly in Modern Industries

Consumer electronics and IoT devices

Surface mount technology (SMT) is key for modern electronics. Devices like smartphones, wearables, and smart home gadgets need to be small and light. SMT helps by fitting many parts onto tiny PCBs. This makes devices work better without getting bigger.

- The global SMT market was worth $5.27 billion in 2023. It is expected to grow 5.8% yearly until 2030.

- IoT devices use SMT to stay lightweight and user-friendly.

- Fitness trackers and other wearables depend on SMT for small size and advanced features.

Using SMT lets you create smaller, smarter products that people want.

Image: Small IoT devices and wearables made with SMT.

Automotive and aerospace innovations

Cars and airplanes need parts that are precise and reliable. SMT helps make these parts better and cheaper. In cars, SMT is used for systems like ADAS, infotainment, and EV components. In airplanes, it ensures safety and top performance.

- SMT lowers costs and improves efficiency for cars and planes.

- Aerospace systems need high-quality PCBs to stay safe and reliable.

With SMT, you can build advanced systems that meet strict industry needs.

Medical devices and industrial applications

Medical and industrial fields use SMT for small, reliable, and powerful devices. In healthcare, SMT helps make portable tools, health monitors, and implants. Factories use SMT for sensors, controllers, and automation systems.

- SMT makes medical devices smaller and better, helping patients.

- Factories benefit from SMT’s ability to produce many parts quickly and well.

By using SMT, you can create new solutions that improve lives and make work easier.

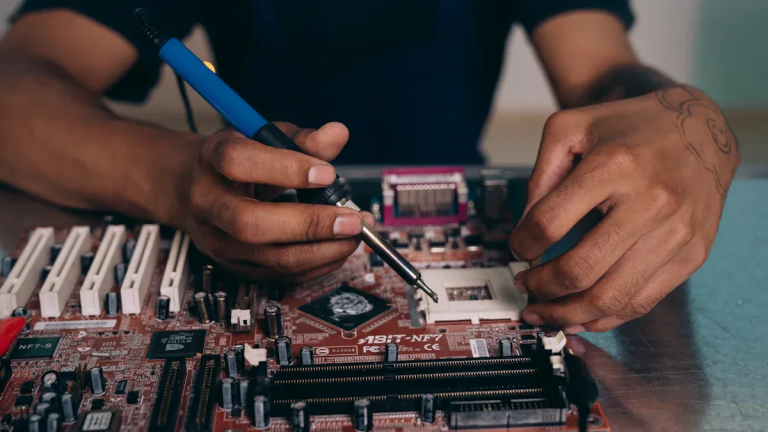

Image: High-tech medical devices and factory tools made with SMT.

Surface mount technology (SMT) has changed how PCBs are made. It helps create smaller, better, and more reliable designs. With SMT assembly, machines work with great accuracy and can handle large tasks. The solder paste step and reflow soldering make strong part connections. Inspection tools check for mistakes to improve quality. Using SMT keeps you ahead in the fast-moving electronics world.

Tip: Improve inspections and accuracy to get the most from SMT.

Image: SMT assembly line showing precise and fast work.

FAQ

Why is SMT better than through-hole technology?

SMT works faster and saves money. It fits more parts on smaller boards. It also supports automation, making it great for modern electronics.

Tip: Choose SMT for big projects to save time and money.

Can SMT handle tough or high-power jobs?

SMT works well for most tasks. But, it’s not as strong as through-hole technology for tough jobs like military or space systems.

How does SMT help with large-scale production?

SMT uses machines to make many PCBs quickly and accurately. This lowers labor costs and keeps quality consistent.

Image: Machines in an SMT assembly line working efficiently.

Note: Keep SMT machines in good shape for the best results.